When you pay $1200 for an AAR hood, you expect more from Stinger Fiberglass

That looks as if the resin and glass was not compacted properly in the corners. Voids/air bubbles are a manufacturing defect which can be easily avoided when proper layup techniques are FOLLOWED.

You are likely to have had to fix that whether or not the shipping container was properly made.

When you get glass parts, examine them closely with an awl or punch along all edges for voids and air bubbles. Dremel them out with tool tips like the first four on the bottom. When I get home, I will try to draw up some pictures and upload them so you can see how to will want to do the edges for better blending the surfaces between the glass and the filler putty/bondo.

Note, these tool tips are SMALL, the shank on these tools is 1/8".

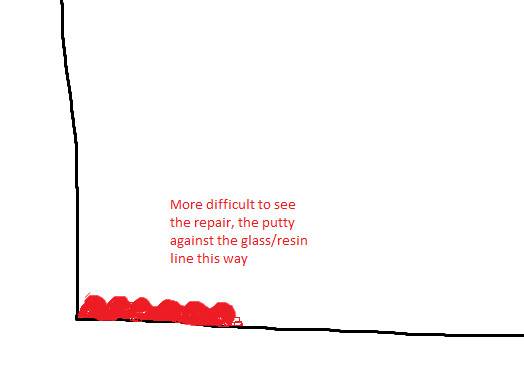

If you scallop the edges of where you cut out material it's more difficult to see the repair line.

Do NOT rush the repair, no NOT start block sanding when the putty/bondo is still wet or uncured. patience is your friend. In fact, when you put the putty on, clean up your tools and go spend some time on FABO re-reading the My Luck thread. Once that's done, the bondo should be cured and you can block it. Don't get too aggressive on rounding the edges.

That looks as if the resin and glass was not compacted properly in the corners. Voids/air bubbles are a manufacturing defect which can be easily avoided when proper layup techniques are FOLLOWED.

You are likely to have had to fix that whether or not the shipping container was properly made.

When you get glass parts, examine them closely with an awl or punch along all edges for voids and air bubbles. Dremel them out with tool tips like the first four on the bottom. When I get home, I will try to draw up some pictures and upload them so you can see how to will want to do the edges for better blending the surfaces between the glass and the filler putty/bondo.

Note, these tool tips are SMALL, the shank on these tools is 1/8".

If you scallop the edges of where you cut out material it's more difficult to see the repair line.

Do NOT rush the repair, no NOT start block sanding when the putty/bondo is still wet or uncured. patience is your friend. In fact, when you put the putty on, clean up your tools and go spend some time on FABO re-reading the My Luck thread. Once that's done, the bondo should be cured and you can block it. Don't get too aggressive on rounding the edges.