pishta

I know I'm right....

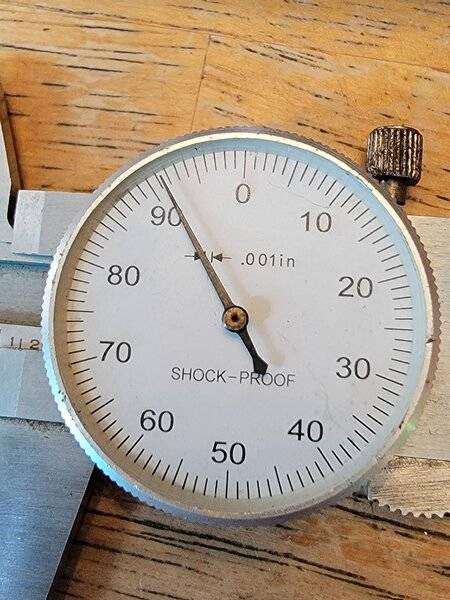

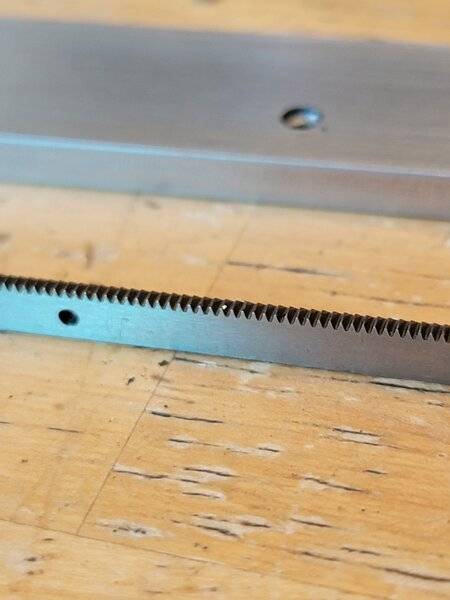

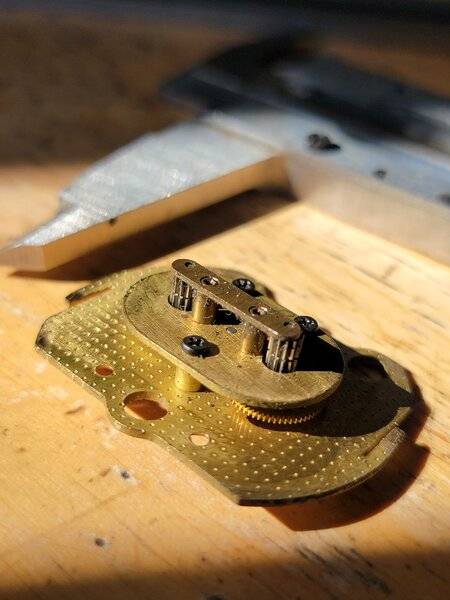

My cheap *** HF dial caliper that I've had for 15 years finally started to give me fits. Would not return to zero repeatable. So...take it a part! A few pics. Key is to pry the bezel ring off and you'll be on your way. Remove the needle with 2 screwdrivers prying up in it at the shaft. It's a female so don't think the pins gonna come out. Take the gace odd and remove the 3 large screws. This will release the dial part. Under that you'll see 2 pinions for the rack and if you look closely under them you'll see one of them has a spring pawled to the brass gear and one has it but does not seem to be attached. Maybe this is my issue as the needle has about 6 thou of play on a locked up dial. If you lock the gears there is no play. I think the spring that looks to be floating should have some tension on it as the other one does? I cleaned it and put it all together , tightening some screws that I found a little loose enough to provide me a smooth travel and I still have the play. There is a brass shim in there that is bowed to provide some tension on the slide, you have to make sure that piece is installed correctly (bowed out) and the pin is in the hole or it won't go back together properly. It will if its not pinned but it will slide out once you start using it. It's the small screw closest to internal jaws and it has a nub on the end that fits in the hole of the shim to anchor it. So its all back together and it's still sloppy unless I snap the jaws to the piece and that swings the needle to its stop but that's not how we do this. There are 3 Phillips screws that hold the pinion retainer down but I stripped one trying to get it out so I didn't get any deeper than, just a visual but I need a new dual SAE/Metric digital caliper anyway so HF gift cards up! It worked for 15 years, not bad for a tool drawer dial caliper who's crystal broke 10 years ago! I kept it in its case after that.

Good job!

Good job!