Squareback vs round back alternator?

Second possible cause is in the wiring.

We see some modifications including that relay.

A relay can help work around some resistance in the run circuit. But there still can be power feed resistance problems, and with changes in load, there will be voltage drop with increased current.

The regulator will respond in an attempt to control the voltage it senses.

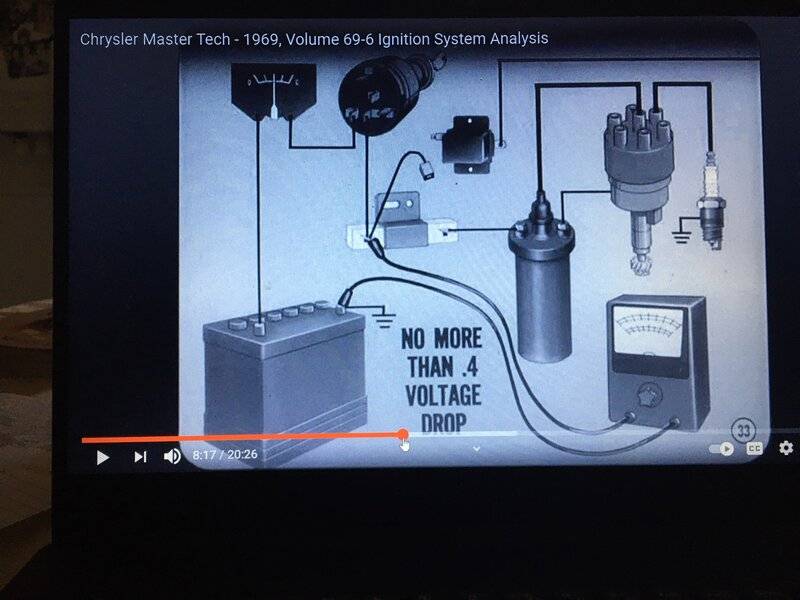

In this 1969 check, Chrysler wanted less than 0.4 Volt between the power sources (battery in this image) and the ignition and field.

Note the field is disconnected in this check. Later there's a check with it connected. That should be less than .55 Volts difference between the battery and the regulator terminal.

Because the problem in this case is voltage regulation, it would be best to repeat the voltage drop measurement between the alternator output and the regulator input/sense terminal while the engine is running.

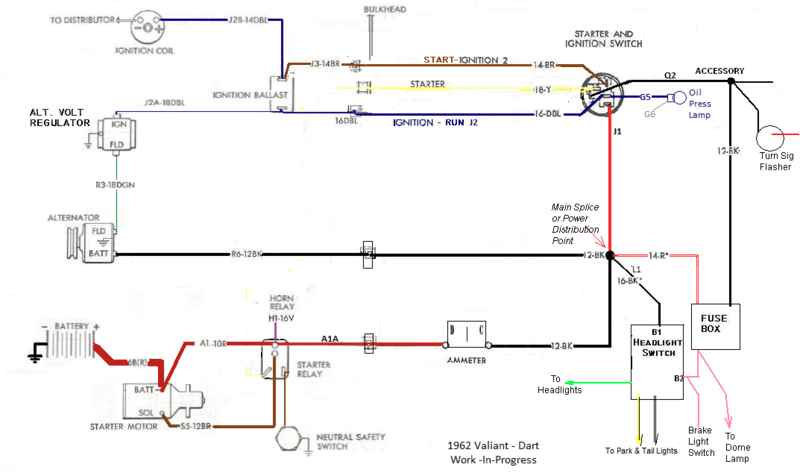

Originally the circuits looked like this.

This is a very simple arrangment.

When the alternator is generating power, current flows to the main splice through one connection.

Then to the key switch, and out to the ignition and voltage regulator.

However, if the R6 wire or connections are damaged, then there will be increasing voltage drop with increasing current flow.

Same goes for resistance or poor connections in the J1 wire, key switch, and Run wires (labelled J2).

Someone installed a relay, possibly to work around a poor connection.

We also often see accessories added to the battery. Perhaps the new fuses were added to the battery circuit. This is generally a poor location in older vehicles because power coming from the alternator does not go directly to the battery. Recharging the battery was a secondary function and a little electrical noise was not a concern.

Second possible cause is in the wiring.

We see some modifications including that relay.

A relay can help work around some resistance in the run circuit. But there still can be power feed resistance problems, and with changes in load, there will be voltage drop with increased current.

The regulator will respond in an attempt to control the voltage it senses.

In this 1969 check, Chrysler wanted less than 0.4 Volt between the power sources (battery in this image) and the ignition and field.

Note the field is disconnected in this check. Later there's a check with it connected. That should be less than .55 Volts difference between the battery and the regulator terminal.

Because the problem in this case is voltage regulation, it would be best to repeat the voltage drop measurement between the alternator output and the regulator input/sense terminal while the engine is running.

Originally the circuits looked like this.

This is a very simple arrangment.

When the alternator is generating power, current flows to the main splice through one connection.

Then to the key switch, and out to the ignition and voltage regulator.

However, if the R6 wire or connections are damaged, then there will be increasing voltage drop with increasing current flow.

Same goes for resistance or poor connections in the J1 wire, key switch, and Run wires (labelled J2).

Someone installed a relay, possibly to work around a poor connection.

We also often see accessories added to the battery. Perhaps the new fuses were added to the battery circuit. This is generally a poor location in older vehicles because power coming from the alternator does not go directly to the battery. Recharging the battery was a secondary function and a little electrical noise was not a concern.