Basket Case Bracket Car

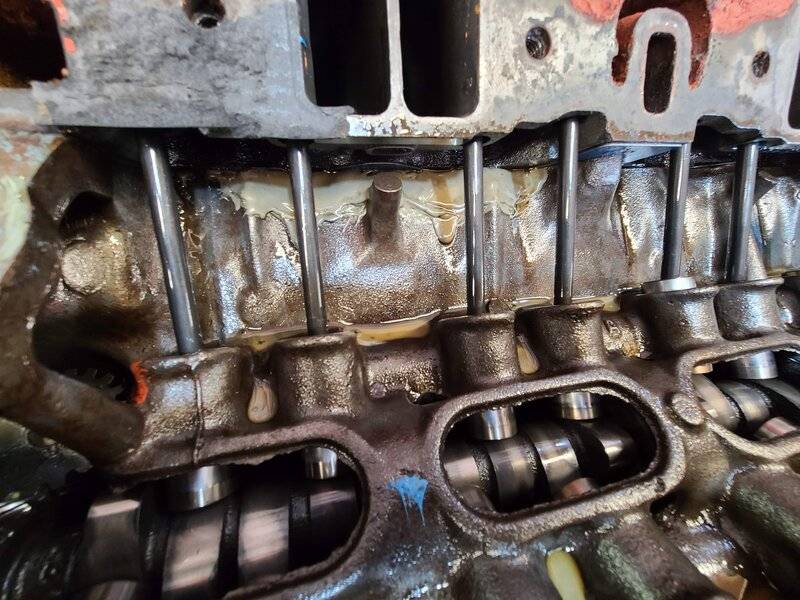

I began stripping it down when I got it home. The engine had a 4" long crack in the upper valley area that had been epoxied. Pretty disappointed in that. Engine had the old trw domes, a set of Bill Miller Engineering alum rods, a polished up steel crank, crane gold rockers, and heavily ported "O" heads. Heads have 2.08 intake valves, and the most porting I've seen on iron heads (may or may not be a good thing). Intake is a Weiand Xcelerator, with Holley 850 set up for alcohol. Basic small tube headers, electric water pump, TCI Rattler balancer.

So I took the block and heads to machine shop, and the block ended up having over 14" of cracks on both sides of valley. Luckily I had a standard bore 340 sitting in the shop that I took in. Heads were cleaned up, pressure tested, valve job, new exh valves and new guides.

The pistons had a weird coating on the domes and skirts, that was flaking off but not easily enough to remove it all without damaging piston, so I scored a set of NOS pistons of the same type, .030 over.

Not having history on the alum rods, I bought some Scat I-beams. Machine shop polished crank and balanced it all, and bored my good block .030.

I have an M1 single plane and a couple options on Holleys I'm going to use, and I decided to get the compression down to around 12:1 hopefully, so I can run 110 gas instead of alky.

Cam will be solid roller. Scored a set of the comp solid body lifters a while back. Not sure what cam brand and size I'll run yet.

Also bought a Kevko rear sump pan since I'll be doing away with the A-body suspension.

I began stripping it down when I got it home. The engine had a 4" long crack in the upper valley area that had been epoxied. Pretty disappointed in that. Engine had the old trw domes, a set of Bill Miller Engineering alum rods, a polished up steel crank, crane gold rockers, and heavily ported "O" heads. Heads have 2.08 intake valves, and the most porting I've seen on iron heads (may or may not be a good thing). Intake is a Weiand Xcelerator, with Holley 850 set up for alcohol. Basic small tube headers, electric water pump, TCI Rattler balancer.

So I took the block and heads to machine shop, and the block ended up having over 14" of cracks on both sides of valley. Luckily I had a standard bore 340 sitting in the shop that I took in. Heads were cleaned up, pressure tested, valve job, new exh valves and new guides.

The pistons had a weird coating on the domes and skirts, that was flaking off but not easily enough to remove it all without damaging piston, so I scored a set of NOS pistons of the same type, .030 over.

Not having history on the alum rods, I bought some Scat I-beams. Machine shop polished crank and balanced it all, and bored my good block .030.

I have an M1 single plane and a couple options on Holleys I'm going to use, and I decided to get the compression down to around 12:1 hopefully, so I can run 110 gas instead of alky.

Cam will be solid roller. Scored a set of the comp solid body lifters a while back. Not sure what cam brand and size I'll run yet.

Also bought a Kevko rear sump pan since I'll be doing away with the A-body suspension.