After MUCH effort yesterday I got my engine, trans and K-Frame dropped as a unit. I said unit. The big issue was the passenger side torsion bar "stuck" in the lower control arm.

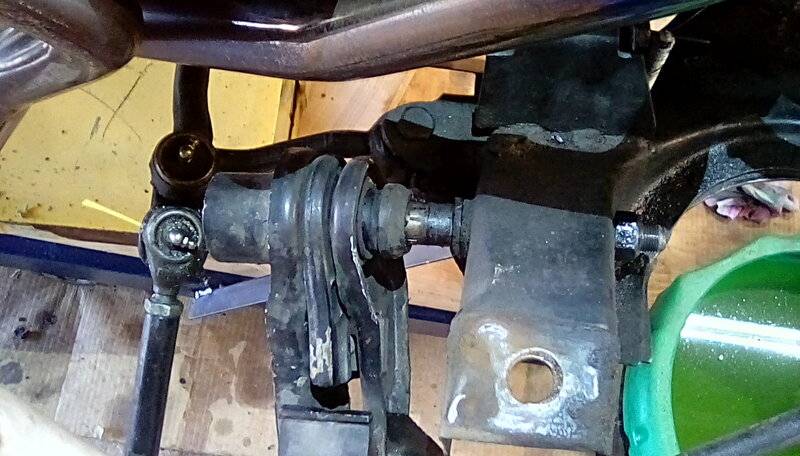

The car is on a lift and I fully loosened both T-Bar adjusters. The driver's side came out easily. On the pass side I had to make a tool and used a hand sledge striking the tool rearward but got little movement. Yes the rear clip was out. I tried loosening the strut rod and control arm shaft nut but to no avail. I also hit the control arm/t-bar socket with the sledge to try to free it up but NFG. I finally got the bar removed by attaching a come-along to the tool I made and hooked into a rear frame hole. Even with the bar beyond the frame socket and a lot of tension on it there wasn't much movement but eventually it freed up with me hitting the control arm socket and driving the arm forward with a HD rod and hand sledge. There was so much force that the control arm pivot shaft actually pulled out of the arm quite a bit. WTF? Ever see this?!?!?!?!?!? Next question is can I just press the pivot shaft back in and call it good?

Before you answer...Note that I rebuilt my suspension with all new T-bars, bushings, shafts, etc about 8K miles 10 years ago and the car is not driven in the rain. The T-bar ends were greased up prior to assembly.

The car is on a lift and I fully loosened both T-Bar adjusters. The driver's side came out easily. On the pass side I had to make a tool and used a hand sledge striking the tool rearward but got little movement. Yes the rear clip was out. I tried loosening the strut rod and control arm shaft nut but to no avail. I also hit the control arm/t-bar socket with the sledge to try to free it up but NFG. I finally got the bar removed by attaching a come-along to the tool I made and hooked into a rear frame hole. Even with the bar beyond the frame socket and a lot of tension on it there wasn't much movement but eventually it freed up with me hitting the control arm socket and driving the arm forward with a HD rod and hand sledge. There was so much force that the control arm pivot shaft actually pulled out of the arm quite a bit. WTF? Ever see this?!?!?!?!?!? Next question is can I just press the pivot shaft back in and call it good?

Before you answer...Note that I rebuilt my suspension with all new T-bars, bushings, shafts, etc about 8K miles 10 years ago and the car is not driven in the rain. The T-bar ends were greased up prior to assembly.