Hello everyone,

the parts have arrived this Wednesday from the US. So I have started to install and wire it the way the workshop manual showed incl. a ballast resistor. The charge voltage is perfekt with new electronic Vreg, it moves between 13,8 V in idle and up to 14,4 V above idle, no fluctuations anymore.

I have installed as well new spark plug wires, a new coil, condenser, spark plugs, ignition switch. The engine fires right up and seems stable so far, a following test drive will show more.

Still a bit chaotic the wiring but it's just for test purposes ...

It took me a while to find the IGN1 wire, it fed a new relay for the horn combined with a second wire going to the positive contact at the ign coil. I understand the purpose of that modification and will care about the horn later, first putting the ignition and charge system into original specs.

Moreover wire IGN2 and 1 were interconnected right behind the ignition switch. There were no ballast resistor before installed so it didn't matter, all available current went to the coil ... Maybe the old coil had an internal ballast resistor?

Old coil:

primary (- -> +) = 1,3 Ohms

secondary (- -> 4) = 9,64 kOhms

new coil:

primary = 1 Ohm

secondary: = 8,8 kOhms

On the lower contact of the ballast resistor I installed IGN 1 wire and IGN from the Vreg IGN. On the upper contact is the ign coil positive wire and IGN 2 wire.

Coming to the voltage for the ignition coil. At idle I measured ~ 12,8 V, above idle up to 13,7 V. Does anyone know what should arrive there? The new coil is a 12 V and it's written "use ext. ballast resistor" (no further specs). While ign switch is at IGN1 it should not exceed 12 Volts that much, right? With the old setup and defektive Vreg there were up to 17 Volts ...

Also I have noticed the AMM just moves a bit to D(echarge) while starting and while the engine is running and the ALT is charging it moves up 2 mm into C(harge) also when all lighting and other users are ON. With the old setup the AMM pointer was very nervous high into C (faulty Vreg....) Note: I just recharged the battery. I'm going to measure current and voltage drop once I figured out if the voltage the the coil + is correct or incorrect and eventually further mods.

Old plugs left: Champion RN14YC, new at the right Denso W14EXR-U

I couldn't get the Champion within a few days, so I cross checked with the WS manual ref no. "AG 42" and the Denso plugs were recommended. Shorter body, resistance the same. What do you think, any recommandations?

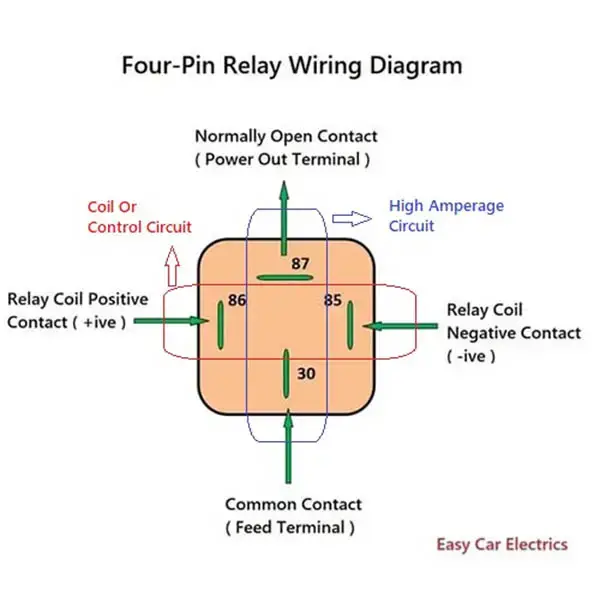

The new horny relay. On the empty conact was IGN1 and a secon wire going to the coil +

New ignition coil