Front subframe sitting on bump stop ?

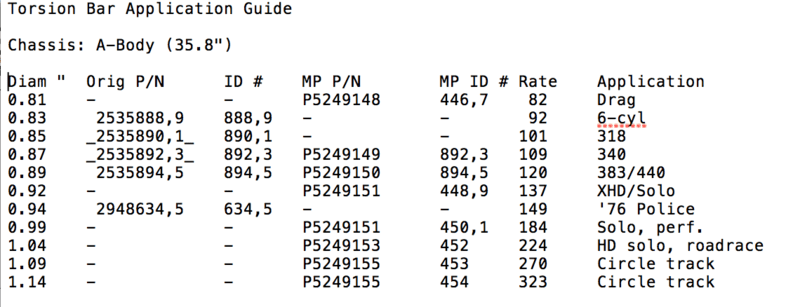

This is the best guide I have for relating the ID #'s, part #'s and diameters. The rates listed in this one are calculated by the author of the chart though, and don't exactly match the rates that Mopar published officially. The difference is probably that these were calculated with a generic constant for spring steel, while Mopar actually used the exact constant based on the metallurgy of the bars. Either that or the author of this chart used a slightly different length for the LCA which is totally possible if it was measured. Again Mopar would have had the exact number.

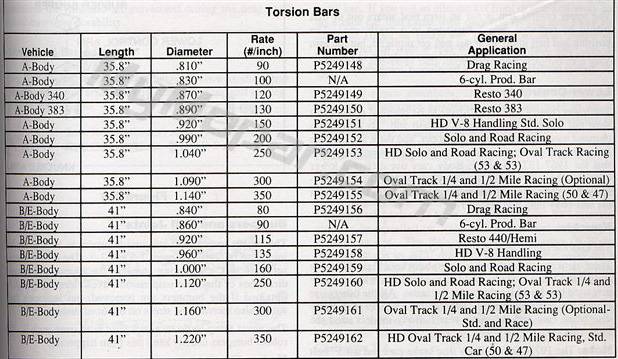

This is a great list of the part #'s and rates, this is the Mopar published data for the rates. But of course it doesn't list the ID #'s on the bars themselves, and it's missing the .85" bar.

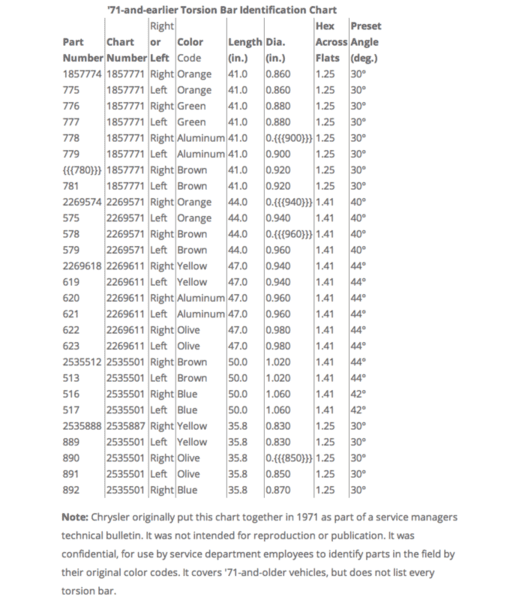

Here's another list, this one shows a few of the bars with ID #'s, diameters, and some of the measurements, as well as the factory paint stripe color you can find on the OE bars.

This isn’t actually true.

For radial tires the best suspension geometry occurs when the LCA is parallel to the ground. That’s when the camber gain matches the performance of radial tires the best. The original geometry and specs was designed for bias ply tires, which perform very differently.

Same for the drop spindles replicating stock geometry- not true. The control arm angles might be the same if you drop the car the full 2”, but the bump steer and roll center still change because of the different axle stub location with respect to the ball joints and tie rod ends.

This is the best guide I have for relating the ID #'s, part #'s and diameters. The rates listed in this one are calculated by the author of the chart though, and don't exactly match the rates that Mopar published officially. The difference is probably that these were calculated with a generic constant for spring steel, while Mopar actually used the exact constant based on the metallurgy of the bars. Either that or the author of this chart used a slightly different length for the LCA which is totally possible if it was measured. Again Mopar would have had the exact number.

This is a great list of the part #'s and rates, this is the Mopar published data for the rates. But of course it doesn't list the ID #'s on the bars themselves, and it's missing the .85" bar.

Here's another list, this one shows a few of the bars with ID #'s, diameters, and some of the measurements, as well as the factory paint stripe color you can find on the OE bars.

This isn’t actually true.

For radial tires the best suspension geometry occurs when the LCA is parallel to the ground. That’s when the camber gain matches the performance of radial tires the best. The original geometry and specs was designed for bias ply tires, which perform very differently.

Same for the drop spindles replicating stock geometry- not true. The control arm angles might be the same if you drop the car the full 2”, but the bump steer and roll center still change because of the different axle stub location with respect to the ball joints and tie rod ends.