Post#10, I don't want this as a "special moment" switch-over, that's easy. If I have a short stroke, high winder hot street engine capable of 8k maybe more, it has to function all the time & on demand. Thx.It’s done all the time with MSD systems with dual pickup distributors and is shown in the manuals delivered in the MSD box. Mostly on race cars running endurance races. Don’t see why you couldn’t run it this way. But it’s also extra work for a street car, when you can just unplug and plug in the new box.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Parallel ignition systems, anybody tried running one?

- Thread starter Killer6

- Start date

-

Scody21

Just send it

Post#10, I don't want this as a "special moment" switch-over, that's easy. If I have a short stroke, high winder hot street engine capable of 8k maybe more, it has to function all the time & on demand. Thx.

Dual pickup distributor, wire both boxes and a sensor switch.

Scody21

Just send it

That's one possibility, I want to hear from somebody who has done it/tried it, thx.

That’s how it’s done. With a dual pickup distributor. You were given answers by a bunch of the guys on here. So yeah, have fun spinning your wheels…

FYI the dual pck up plates from the lean burn have a 5-degree difference in pick up positions so you are aware of it. One is for start one is for run. Also they have no vacuum advance provision so the distributor would be all mechanical advance only. Just FYI

Last edited:

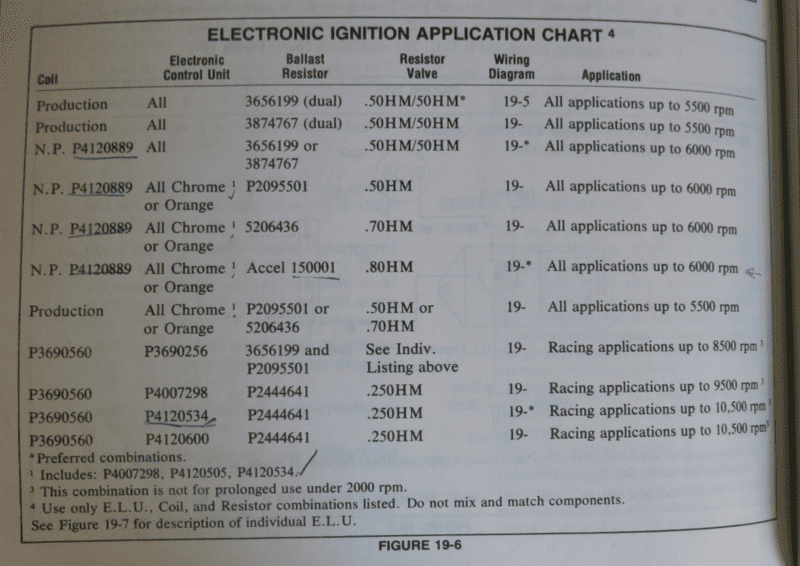

Yes I can between the mock up and a scope. Did a bit comparing ballasts yesterday with different ecu/s Interesting results, kind of what I thought. Have to get it on a spreadsheet. Ballasts make a huge difference in the amp draw and heat created. In a nut shell the higher the resistor the less heat created, explains why the race box will wiithstand the daily driver. Draw back it will not perform as well basically the same with all of the ones I tested.Hops when you test these Ignition Modules/ECUs

What coil are you using in your tests ?

And can you test up to 5500-6000-6500 RPMs to see when everything starts to head south if either the coil or box

Thanx Scott

bee1971

Well-Known Member

Excellent - Awesome setup !

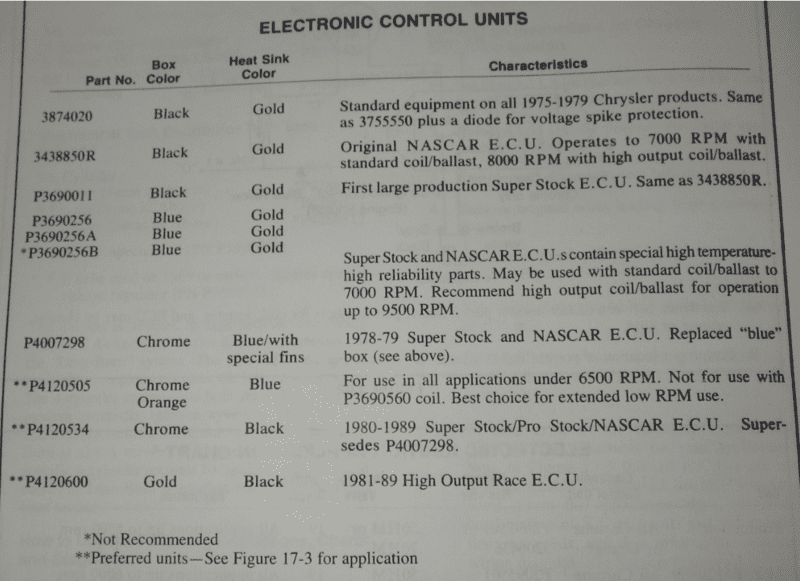

I see in that top photo your running a factory Chrysler ECU #3874020 5 Pin

Is that a Standard UC12 Coil - 1.5 OHM ?

That’s why I was asking about different combinations and RPMs , as I have tested so many of these on my car with different results , and RPM breakdown from 4500 RPMs - 5500 RPMs etc.

Coils are the biggest issue , especially reliability on the street - I stay away from the Blaster 2 coils or anything with a lower resistance designed for CDI Ignition type systems

Accel - Pertronix - Edelbrock etc. all make so called Performance type oil filled canister coils with a Primary resistance of around 1.5 OHMs

Standard SMP has there UC12

Even those factory Chrysler ECUs seem to breakdown around 5000 - 5500 RPMs , but again that could be an result of these Chinese oil filled canister coils - Ballast Resistors vary from .5 to 1.5 OHM resistance that are available today

Like I mentioned earlier Mopar doesn’t make those .25 OHM resistors anymore along with there Mopar Performance ECUs or a made in the USA canister oil filled coil

Would like to see some of your results when you have a chance

Peace , thanx for your time

I see in that top photo your running a factory Chrysler ECU #3874020 5 Pin

Is that a Standard UC12 Coil - 1.5 OHM ?

That’s why I was asking about different combinations and RPMs , as I have tested so many of these on my car with different results , and RPM breakdown from 4500 RPMs - 5500 RPMs etc.

Coils are the biggest issue , especially reliability on the street - I stay away from the Blaster 2 coils or anything with a lower resistance designed for CDI Ignition type systems

Accel - Pertronix - Edelbrock etc. all make so called Performance type oil filled canister coils with a Primary resistance of around 1.5 OHMs

Standard SMP has there UC12

Even those factory Chrysler ECUs seem to breakdown around 5000 - 5500 RPMs , but again that could be an result of these Chinese oil filled canister coils - Ballast Resistors vary from .5 to 1.5 OHM resistance that are available today

Like I mentioned earlier Mopar doesn’t make those .25 OHM resistors anymore along with there Mopar Performance ECUs or a made in the USA canister oil filled coil

Would like to see some of your results when you have a chance

Peace , thanx for your time

Last edited:

The .25 ohm resistors when you find them are usually $65+ now. I will post them when I get done just using a stock coil now on the mock up. Maybe one day I will do coils.

The other angle, besides the dual-pickups being non-synchronous, is that the plate is fixed, so no vac advance. The difference in pickup timing could be worked to an advantage, but I vow to make the vac can work w/o causing roughness/surging this time, patience patience......

I may end up simply having a 2nd .5 ohm ballast switch on parallel to the normal running one at WOT.

I may end up simply having a 2nd .5 ohm ballast switch on parallel to the normal running one at WOT.

Swinger 340

Well-Known Member

Not an expert here, but I believe if it's not broke, don't fix it. I have been running a duel point Accel distributor along with its Super coil and a second (2) ballast Resistors for over 42 years in my 340 (van). I also have a 69 Swinger 340(in photo) and run the stock Prestolite duel point, with a single Ballast. Only had to change the Ballast Resistors once, each. I just changed the plugs, points, condenser, rotor and cap for the first time (Dart), with over 65,000 miles on those parts. The trick is to change all the ignition parts at the same time. A old or weak part will play on the new ones. Engine "Blow-by" will also have a negative effect on your distributor, weather points or electronic. Some distributor caps have "vents", so be sure you face the opening to the rear so not to allow any contaminants to enter. A engine miss could be just a little water, oil or dirt in the cap. Clean often!!!!!

This is not a service/misfire issue, thanks.Not an expert here, but I believe if it's not broke, don't fix it. I have been running a duel point Accel distributor along with its Super coil and a second (2) ballast Resistors for over 42 years in my 340 (van). I also have a 69 Swinger 340(in photo) and run the stock Prestolite duel point, with a single Ballast. Only had to change the Ballast Resistors once, each. I just changed the plugs, points, condenser, rotor and cap for the first time (Dart), with over 65,000 miles on those parts. The trick is to change all the ignition parts at the same time. A old or weak part will play on the new ones. Engine "Blow-by" will also have a negative effect on your distributor, weather points or electronic. Some distributor caps have "vents", so be sure you face the opening to the rear so not to allow any contaminants to enter. A engine miss could be just a little water, oil or dirt in the cap. Clean often!!!!!

-