A833 no shift

I've read all the responses, thanks!

Yes the car creeps a little in 2nd gear with clutch in.

Yes it goes into 4th gear with pressure on the stick when engine is shut off.

Update:

I'll remove the trans and clutch soon. It could be a couple weeks though as I'm collecting parts, manpower and putting a plan together. Not the eaiest thing to do lying on a hunk of cardboard and the car is kept at a friend's house away from my home where I have access to all my tools. Luckily I have a couple car buddies and my gearhead son to lend a hand.

I injured my primary (right) hand last Fall and have an appointment with a surgeon this Tuesday. I'd like to get this done before the surgery. Kind of funny, now that I'm converting this one to floor shift and going auto to manual on my 68, I used to joke about developing a leg problem and not being able to operate a clutch. Ha, ironic that right now it actually hurts to grip a 4 speed ball.

Things I'm going to do:

I've decided to go back to a stock size clutch for the time being. (No turbo in the near future) I bought a very nice LUK clutch from Rockauto. I can tell the 10" HD in there now is straining the stock linkage. For example, the ball end pivot bracket that attaches to the frame rail is a stamping retained with 3 small screws. If that develops into a problem, I have the parts in my stash to change to the 67 and up through-the-rail ball stud mount but that ain't happening now.

The FSM states when using the pilot bushing installation tool that it automatically sizes the ID of the bushing when the tool is removed. I can find no reference to what that dimension should be. None! I seem to recall measuring the new uninstalled bushing last fall at .754. Assuming that the interference fit is .002 it could very well be that it had an installed ID of .752. It was so tight last summer that the 3 speed trans would not go back in when prepping for Carlisle. Everything was good except it would just go clunk, about an inch short, because the input shaft was butting against the end of the bushing. I figured out that the plastic installation tool was not accurate enough so we eventually just snugged up the pressure plate screws so we had a little float in the disc. I just measured the new plastic installation tool included with the LUK and it's about .732 diameter, almost .020 under the actual input shaft diameter.

Later, when installing the 4 speed, I ground a more generous chamber on the end of the input shaft and using a Dremel, increased the lead-in chamber on the bushing. We also used the actual 3 speed trans (only 60 lbs) as the installation tool without the BH in place. I have a real install tool on order from Brewers made from a junk input shaft.

This new LUK kit came with 2 new bushings and they measure .752.

List of things to do:

1. Check clutch departure again. I have the pedal free play about 1/4-1/2" now. Last fall, departure was .050.

2. Measure installed bushing ID. Perhaps ream it larger.

3. Measure bore runout again. Last fall it was .0075. (FSM spec is .008) The smallest offset dowels available are .007.

4. Check BH face runout.

5. Check crank end play. It was well within spec when I completely rebuilt the engine 10,000 miles ago. I'm well aware of this as I try to start the car in neutral with the clutch out, especially on a cold start, to minimize thrust bearing wear.

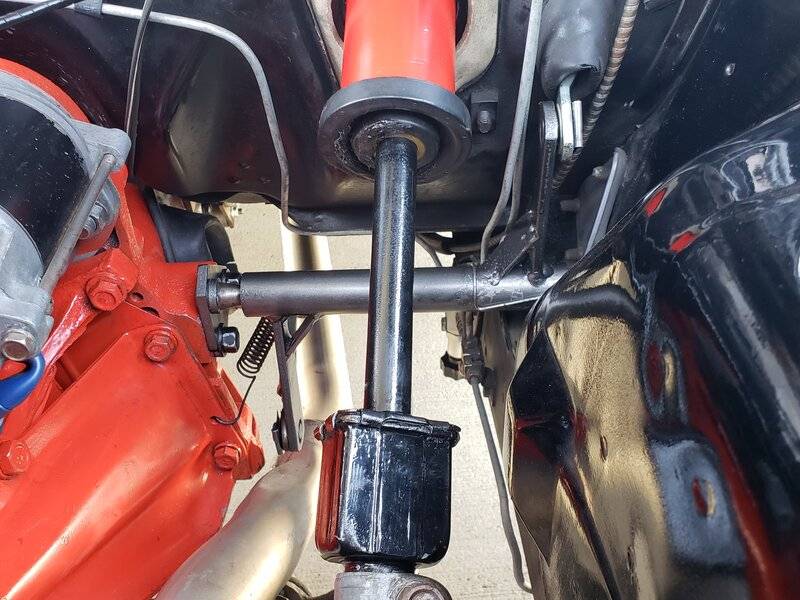

That's it for now. Here's a pic of the present linkage geometry. Looks pretty good except the lower arm could be tweaked about 1/2" to the center of the car to square up the clutch fork push rod.

I've read all the responses, thanks!

Yes the car creeps a little in 2nd gear with clutch in.

Yes it goes into 4th gear with pressure on the stick when engine is shut off.

Update:

I'll remove the trans and clutch soon. It could be a couple weeks though as I'm collecting parts, manpower and putting a plan together. Not the eaiest thing to do lying on a hunk of cardboard and the car is kept at a friend's house away from my home where I have access to all my tools. Luckily I have a couple car buddies and my gearhead son to lend a hand.

I injured my primary (right) hand last Fall and have an appointment with a surgeon this Tuesday. I'd like to get this done before the surgery. Kind of funny, now that I'm converting this one to floor shift and going auto to manual on my 68, I used to joke about developing a leg problem and not being able to operate a clutch. Ha, ironic that right now it actually hurts to grip a 4 speed ball.

Things I'm going to do:

I've decided to go back to a stock size clutch for the time being. (No turbo in the near future) I bought a very nice LUK clutch from Rockauto. I can tell the 10" HD in there now is straining the stock linkage. For example, the ball end pivot bracket that attaches to the frame rail is a stamping retained with 3 small screws. If that develops into a problem, I have the parts in my stash to change to the 67 and up through-the-rail ball stud mount but that ain't happening now.

The FSM states when using the pilot bushing installation tool that it automatically sizes the ID of the bushing when the tool is removed. I can find no reference to what that dimension should be. None! I seem to recall measuring the new uninstalled bushing last fall at .754. Assuming that the interference fit is .002 it could very well be that it had an installed ID of .752. It was so tight last summer that the 3 speed trans would not go back in when prepping for Carlisle. Everything was good except it would just go clunk, about an inch short, because the input shaft was butting against the end of the bushing. I figured out that the plastic installation tool was not accurate enough so we eventually just snugged up the pressure plate screws so we had a little float in the disc. I just measured the new plastic installation tool included with the LUK and it's about .732 diameter, almost .020 under the actual input shaft diameter.

Later, when installing the 4 speed, I ground a more generous chamber on the end of the input shaft and using a Dremel, increased the lead-in chamber on the bushing. We also used the actual 3 speed trans (only 60 lbs) as the installation tool without the BH in place. I have a real install tool on order from Brewers made from a junk input shaft.

This new LUK kit came with 2 new bushings and they measure .752.

List of things to do:

1. Check clutch departure again. I have the pedal free play about 1/4-1/2" now. Last fall, departure was .050.

2. Measure installed bushing ID. Perhaps ream it larger.

3. Measure bore runout again. Last fall it was .0075. (FSM spec is .008) The smallest offset dowels available are .007.

4. Check BH face runout.

5. Check crank end play. It was well within spec when I completely rebuilt the engine 10,000 miles ago. I'm well aware of this as I try to start the car in neutral with the clutch out, especially on a cold start, to minimize thrust bearing wear.

That's it for now. Here's a pic of the present linkage geometry. Looks pretty good except the lower arm could be tweaked about 1/2" to the center of the car to square up the clutch fork push rod.