I do not want to drill holes for the pilot type cutter, so. How long do the other type last? I have approximately 50 spot welds to drill out. They can cost upwards of $30. a piece

Use cutting oil and keep the speed down?

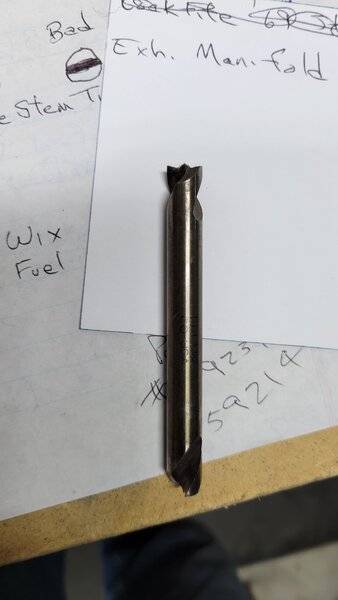

I borrowed some from a friend, they are so dull that they need to be replaced. So how many should I buy?

Use cutting oil and keep the speed down?

I borrowed some from a friend, they are so dull that they need to be replaced. So how many should I buy?