Guage testing and adjustments

As some of you know I fried my temp gauge when my mechanical IVR lost the heater wire full volting the temp and fuel gauge.

It still functions, but normal operating temp is just at the low tick of the temp gauge, normally it would be 1/4 past the low tick.

(Note: the temp gauge is 67 so the normal range is shifted to the right)

Luckly the fuel gauge functions as expected.

EDIT--

I have been collecting clusters to gather good working gauges. So far I have I really good used, 2 less than great but functional, and I lucked in on a NOS temp gauge.

To date I have 4 clusters and one NOS Temp gauge.

all 4 clusters have snap on speedo cables so none of them are 67.

2 of them have the shifted temp "normal" ranges. I don't know what year the shifted "Normal" became centered.

End EDIT----

I have another cluster inbound and it looks promising.

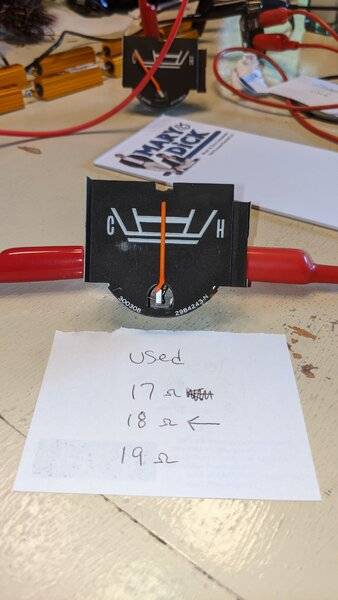

I figured I would test the used gauge assuming the NOS gauge is the most accurate.

I set up a series of 100w resisters and a series of 18 awg jumper cables.

I can do any resistance from 1 ohm to 100 ohms.

I have a 12v power supply and an rt-eng.com IVR4 limiter.

I set up the gauges and resisters etc.

Actual resistance values below, the input voltage to the IVR was 13.66v

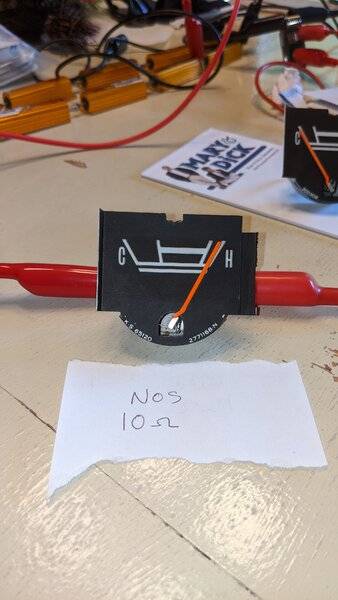

10 ohms NOS

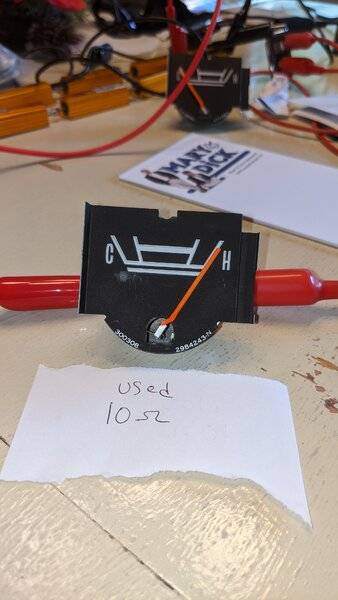

10 ohms Used

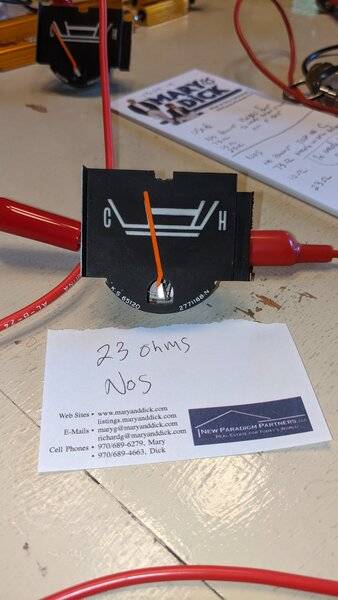

23 ohms NOS

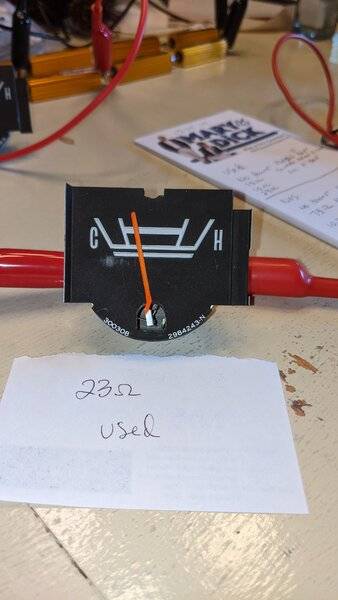

23 ohms used

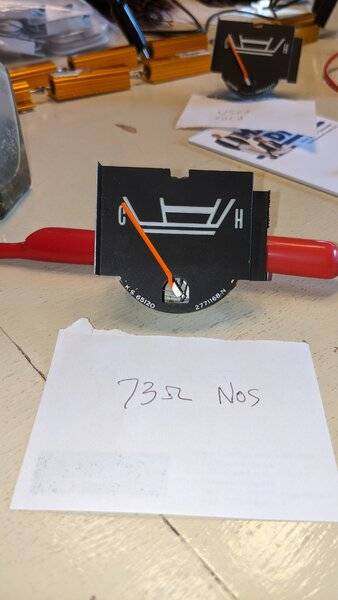

73 ohms NOS

73 ohms used

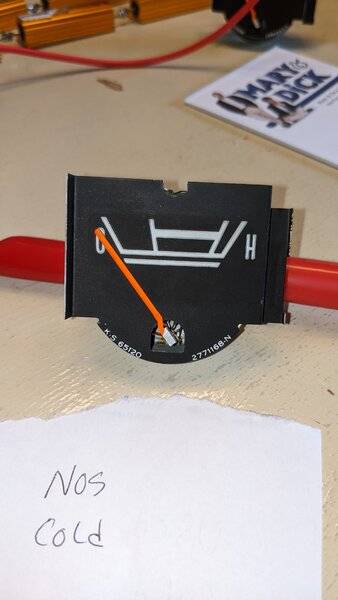

NOS no voltage (cold, 5 minutes)

Used no voltage (cold, 5 minutes)

Here is the interesting thing...

23 ohms has been the defacto 1/2 gauge resistance value. As you can see the 23 ohm readings were around 1/3 reading.

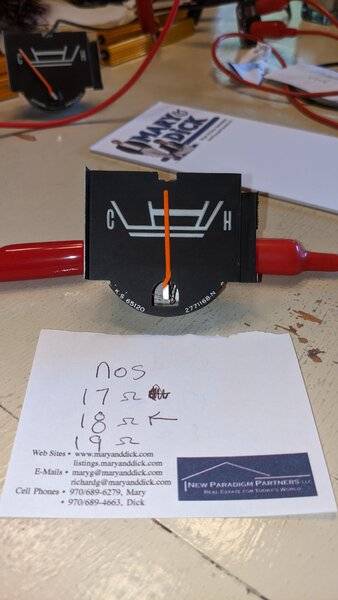

17 to 18 ohm caused half gauge reading

18 ohms NOS

18 ohms used

My conclusion is the used gauge is about as accurate as it can be.

I had messed with the upper and lower limits in the past and had no idea where it should read.

I started with adjusting the high limit and got it on the line when 10 ohms was applied.

Then I adjusted the low limit and got the needle on the line with 73 ohms

I then went back and forth, high and low, adjusting one affected the other till I got a happy medium.

Now both gauges read about the same.

It will be interesting to see how the incoming cluster works out.

Either way I have 2 options to replace my bad gauge.

As some of you know I fried my temp gauge when my mechanical IVR lost the heater wire full volting the temp and fuel gauge.

It still functions, but normal operating temp is just at the low tick of the temp gauge, normally it would be 1/4 past the low tick.

(Note: the temp gauge is 67 so the normal range is shifted to the right)

Luckly the fuel gauge functions as expected.

EDIT--

I have been collecting clusters to gather good working gauges. So far I have I really good used, 2 less than great but functional, and I lucked in on a NOS temp gauge.

To date I have 4 clusters and one NOS Temp gauge.

all 4 clusters have snap on speedo cables so none of them are 67.

2 of them have the shifted temp "normal" ranges. I don't know what year the shifted "Normal" became centered.

End EDIT----

I have another cluster inbound and it looks promising.

I figured I would test the used gauge assuming the NOS gauge is the most accurate.

I set up a series of 100w resisters and a series of 18 awg jumper cables.

I can do any resistance from 1 ohm to 100 ohms.

I have a 12v power supply and an rt-eng.com IVR4 limiter.

I set up the gauges and resisters etc.

Actual resistance values below, the input voltage to the IVR was 13.66v

- 10.4 ohms

- 17.3 ohms

- 18.3 ohms

- 23.4 ohms

- 73.5 ohms

10 ohms NOS

10 ohms Used

23 ohms NOS

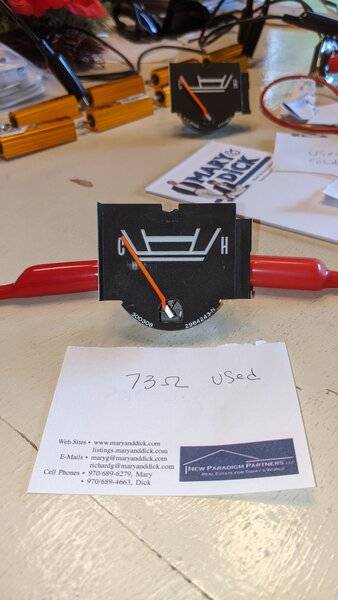

23 ohms used

73 ohms NOS

73 ohms used

NOS no voltage (cold, 5 minutes)

Used no voltage (cold, 5 minutes)

Here is the interesting thing...

23 ohms has been the defacto 1/2 gauge resistance value. As you can see the 23 ohm readings were around 1/3 reading.

17 to 18 ohm caused half gauge reading

18 ohms NOS

18 ohms used

My conclusion is the used gauge is about as accurate as it can be.

I had messed with the upper and lower limits in the past and had no idea where it should read.

I started with adjusting the high limit and got it on the line when 10 ohms was applied.

Then I adjusted the low limit and got the needle on the line with 73 ohms

I then went back and forth, high and low, adjusting one affected the other till I got a happy medium.

Now both gauges read about the same.

It will be interesting to see how the incoming cluster works out.

Either way I have 2 options to replace my bad gauge.