pishta

I know I'm right....

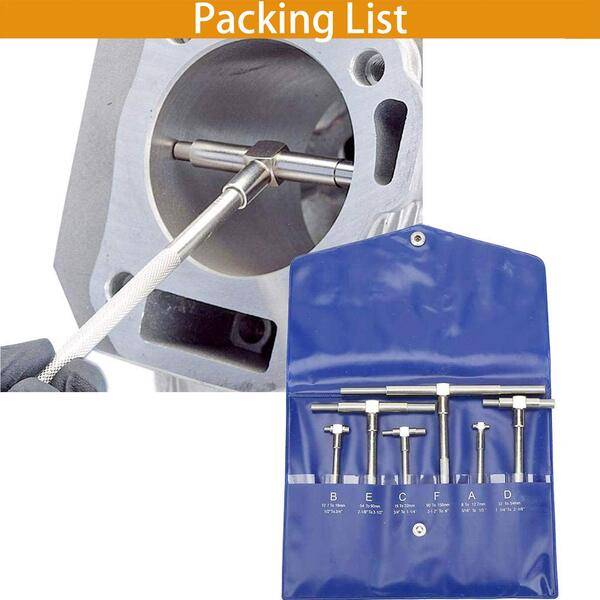

Are these accurate? Seems the diameter of the ends would prevent them from hitting the cylinder wall at the right angle >> (| << to see the entire diameter? Or would you measure across the opposites?

For this price (https://www.amazon.com/dp/B087CKYLW9/?tag=fabo03-20) you could get a cheap caliper to boot (https://www.amazon.com/dp/B082DV3LC2/?tag=fabo03-20) and still be under 1/2 of that tool, but it would be nice to have...... You will also need a 3-4" or 4-5" micrometer to measure the snap gauge once it's out of the bore obviously. For that money just get one of these https://www.amazon.com/dp/B000J4K016/?tag=fabo03-20

but what taper, equal to the smallest bore size for that sized tool?The ends that make contact with the ID of what you’re measuring are not flat. They have some taper to them.

It comes with that little control piece....^^^^^^^^^^^^^^^^^^good instructions!!!!!!!!!!!!!!!!

Thats a good price on a dial bore gauge, but you need standards to certify it.

That would make sense, most likely slightly smallerbut what taper, equal to the smallest bore size for that sized tool

Same here!FWIW a set of decent calipers isn't exactly cheap. These are my go to at work

I use those for checking ports.Are these accurate? Seems the diameter of the ends would prevent them from hitting the cylinder wall at the right angle >> (| << to see the entire diameter? Or would you measure across the opposites?

View attachment 1715931317

Is this it?I use those for checking ports.

They'll definitely work.

Jegs has a 100 dollar or so bore gauge that works great. That's what I use... but the snap gauges and a micrometer will do it, just takes longer...with the gauge you can just run up n down and see how tapered and oor it is.

Yep. You can check not only cyl bores...but rods,mains etc.