70 Duster runs rough or dies when up to operating temps

Crackedback is giving you good advice. You have nothing to lose and all to gain by backing the fuel pressure down to 5.5 psi or less.

With winter fuel and hot temperatures, its that much more likely to be getting high fuel levels in the bowl. 4 psi is plenty to keep the bowls filled driving around and in idle. I don't know that's the problem but again nothing to lose and all to gain.

The fact it runs good cold suggests the idle mix may be rich or the fuel levels were high. However there seems to be some inconsistancy in that so don't see that as a clear cause - effect.

Establishing fuel level is one of the first things to do. That's why I covered it first.

Close to first is establishing timing. However you have some wiring questions and those take precedent.

The ballast resistor itself is non-directional. It will .5 to .7 ohms whether the current flows left to right or right to left. With the electronic ECU resistance should closer to 0.5 ohms. So far not seeing this as the issue but make sure resistance is in this range as many aftermarket ones peple are reporting as over an ohm.

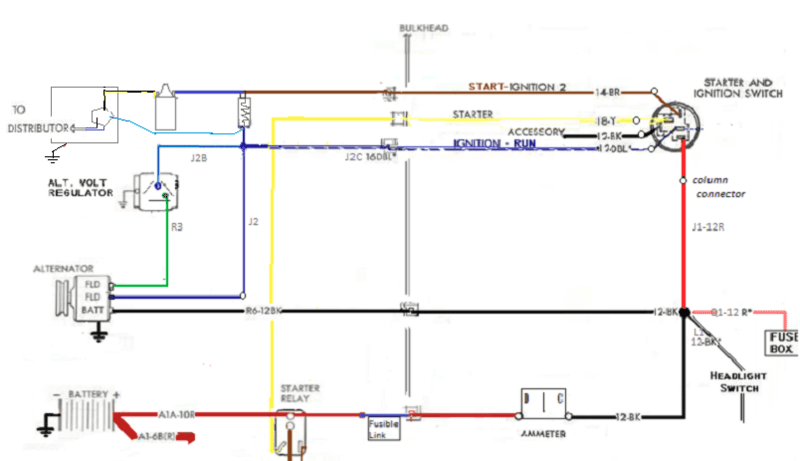

The 16 gage blue or blue with stripe wire is power supply with key in run. It should be very close to the same voltage as the power source.

HOWEVER, you found 12.7 V at feed side of the resistor while the alternator is producing 14.1 Volts. That's a problem.

Additionally, you found the battery was only seeing 13.3 Volts when the alternator was producing at 14.1 V - also a problem.

Those two measurements indicate

1. resistance between the alternator output and the battery.

2. resistance between the main splice and the ballast resistor.

Next time note the current on the ammeter when measuring these voltages. That will further clarify where the problems are as well as the severity.

Now timing

If that vacuum is at 800 rpm in Park then may WAG is thats a cam with around 270 adv duration.

Crackedback is giving you good advice. You have nothing to lose and all to gain by backing the fuel pressure down to 5.5 psi or less.

With winter fuel and hot temperatures, its that much more likely to be getting high fuel levels in the bowl. 4 psi is plenty to keep the bowls filled driving around and in idle. I don't know that's the problem but again nothing to lose and all to gain.

The fact it runs good cold suggests the idle mix may be rich or the fuel levels were high. However there seems to be some inconsistancy in that so don't see that as a clear cause - effect.

Establishing fuel level is one of the first things to do. That's why I covered it first.

Close to first is establishing timing. However you have some wiring questions and those take precedent.

The ballast resistor itself is non-directional. It will .5 to .7 ohms whether the current flows left to right or right to left. With the electronic ECU resistance should closer to 0.5 ohms. So far not seeing this as the issue but make sure resistance is in this range as many aftermarket ones peple are reporting as over an ohm.

The 16 gage blue or blue with stripe wire is power supply with key in run. It should be very close to the same voltage as the power source.

As Dana wrote, having lower voltage on the coil side of the resistor when the engine is running is correct.

HOWEVER, you found 12.7 V at feed side of the resistor while the alternator is producing 14.1 Volts. That's a problem.

Additionally, you found the battery was only seeing 13.3 Volts when the alternator was producing at 14.1 V - also a problem.

Those two measurements indicate

1. resistance between the alternator output and the battery.

2. resistance between the main splice and the ballast resistor.

Next time note the current on the ammeter when measuring these voltages. That will further clarify where the problems are as well as the severity.

Depending on how the pump is wired in, and the type of pump, this could be making the problems worse.

Now timing

If that's at 700 rpm that would be plenty for a stock 318, but your cam is not stock.

When measuring at 800 rpm with a parts store distributor, its likely that the advance has begun. Take some timing measurements at higher and lower rpm if at all possible. Its possible, and common, to set timing at 800 rpm or more, then when the transmission is in gear and the engine rpm goes down, timing goes down. I don't think this is the cause of the rough running you're experiencing but important to be aware of when setting 'iniital'. Whether stock or hot rodded, knowing the rpm of the timing measurement is important.