I was watching this video about drag on aircraft, and I got to thinking of the illustrated soccerball as a cross section of a valve stem in the airflow of the intake and exhaust ports.

another video on the subject

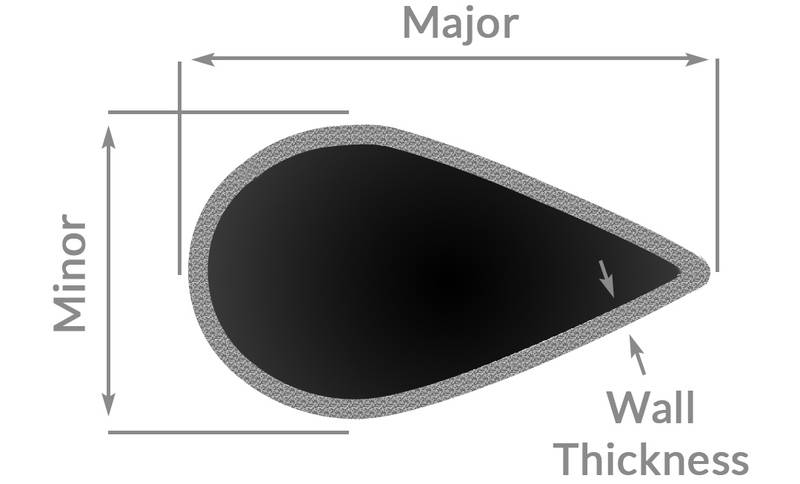

I was thinking about sleeving the valve stem with a tube with a cross section thus with the air flow direction from left to right;

Depending on the speed of the air flow, I suspect that you would want to have different shapes for your airfoil around the valve stem to optimize airflow.

I am guessing that something is better than nothing though. Has anyone seen or heard of this tested as applied to valve stems?

another video on the subject

I was thinking about sleeving the valve stem with a tube with a cross section thus with the air flow direction from left to right;

Depending on the speed of the air flow, I suspect that you would want to have different shapes for your airfoil around the valve stem to optimize airflow.

I am guessing that something is better than nothing though. Has anyone seen or heard of this tested as applied to valve stems?