Well today I ordered a new cam for my W2 408.

W2 408 build

The engine has treated me very well, but I always felt I had left quite a bit on the table. The engine pulls very hard, but I was limiting the RPM to 6200 max for safety due to the hydraulic roller setup. I have decided pull the juice roller out, and simplify things, with a solid flat tappet cam. I spoke with several grinders and decided upon a custom grind from Bullet Cams.

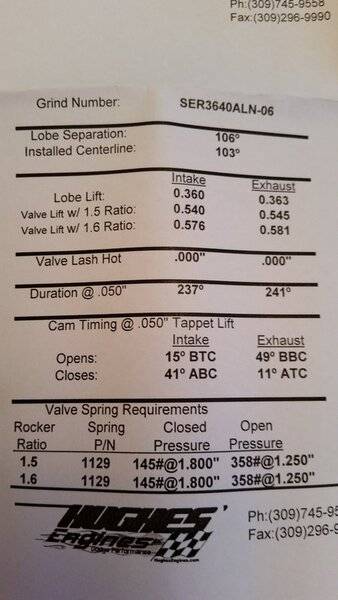

The new stick is single pattern, with the following lobes.

280 advertised, 251@ 0.050, .371 lobe lift (1.6 rockers), 106LSA, .013 lash.

Having a good idea of what I was after, I had Chris, at Bullet Cams help me with the details. I asked for lobes with a degree of intensity that would take advantage of performance, but not beat up the valve train, as the car does see a lot of street miles. Although the idea was to allow me to run the RPM up a little more on the top end, Chris feels this cam will make more power all over. (@Rat Bastid) I took your advice on mentioning I may put a tunnel ram on in the future, Chris indicated this shorter duration cam would be a great compromise for either single plane or tunnel ram. The single pattern, combined with 106LSA should prevent me from having to RPM like mad to make the tunnel ram work. I figured you may like the single pattern also, LOL. Cam is 10 weeks out, likely will be a winter swap out. I'll post the current cam card for comparison.

W2 408 build

The engine has treated me very well, but I always felt I had left quite a bit on the table. The engine pulls very hard, but I was limiting the RPM to 6200 max for safety due to the hydraulic roller setup. I have decided pull the juice roller out, and simplify things, with a solid flat tappet cam. I spoke with several grinders and decided upon a custom grind from Bullet Cams.

The new stick is single pattern, with the following lobes.

280 advertised, 251@ 0.050, .371 lobe lift (1.6 rockers), 106LSA, .013 lash.

Having a good idea of what I was after, I had Chris, at Bullet Cams help me with the details. I asked for lobes with a degree of intensity that would take advantage of performance, but not beat up the valve train, as the car does see a lot of street miles. Although the idea was to allow me to run the RPM up a little more on the top end, Chris feels this cam will make more power all over. (@Rat Bastid) I took your advice on mentioning I may put a tunnel ram on in the future, Chris indicated this shorter duration cam would be a great compromise for either single plane or tunnel ram. The single pattern, combined with 106LSA should prevent me from having to RPM like mad to make the tunnel ram work. I figured you may like the single pattern also, LOL. Cam is 10 weeks out, likely will be a winter swap out. I'll post the current cam card for comparison.

Last edited:

I think you're on the right track. There's just not that many head-to-head solid flat tappet /roller hydraulic comparison out there at least I haven't read too much.

I think you're on the right track. There's just not that many head-to-head solid flat tappet /roller hydraulic comparison out there at least I haven't read too much.