'65 Barracuda 273 with 9 1/2" Bellhousing 2465523.

I put one of the 3 Finger Borg and Beck Style Clutch from Brewers in... (CP 10 I Think)

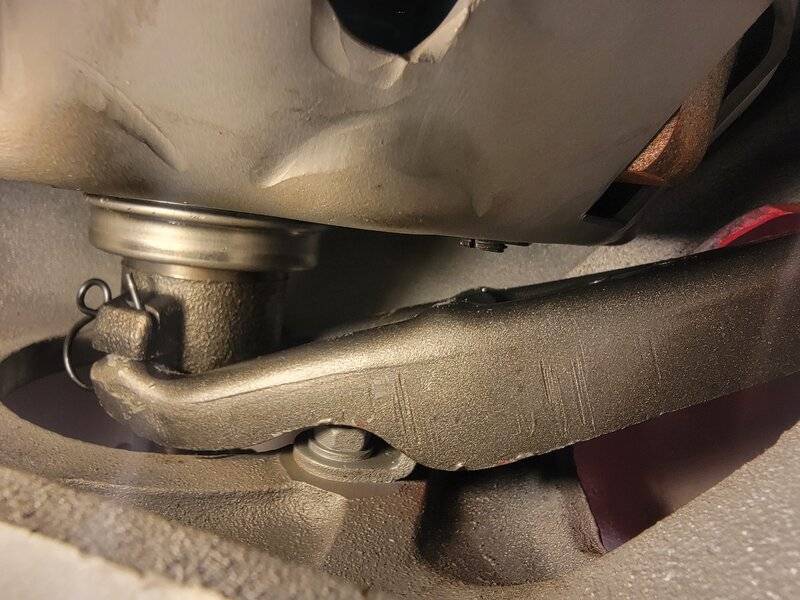

I have a '65 10 1/2" Fork which I think is Correct???

The Provided T.O. Bearing sits back too far and forces the Fork All-The-Way-Forward on the Outside. Is it possible that I just have the wrong Pivot inside?

Wrong T.O. Bearing? Please Advise.

Thanks To All

-eric

I put one of the 3 Finger Borg and Beck Style Clutch from Brewers in... (CP 10 I Think)

I have a '65 10 1/2" Fork which I think is Correct???

The Provided T.O. Bearing sits back too far and forces the Fork All-The-Way-Forward on the Outside. Is it possible that I just have the wrong Pivot inside?

Wrong T.O. Bearing? Please Advise.

Thanks To All

-eric

Last edited: