Hey guys, I’ve been trying to get my fresh built 440 RamCharger running right, and haven’t had much luck. I haven’t been able to spend much time with it lately, so I’m hoping someone here can point me in the right direction. I set the base timing at 16btdc, (haven’t checked total timing yet. I know I should). At first I bolted the carb on, and was able to break-in the engine. Whenever I try to accelerate at all, it falls on its face and pops out of the carb, sometimes stalling the engine.

Here’s some details.

440 big block/manual transmission

Holley 770 street avenger (single pumper)

Aluminum dual plane intake

452 iron heads

Forged aluminum pistons (9:1 compression)

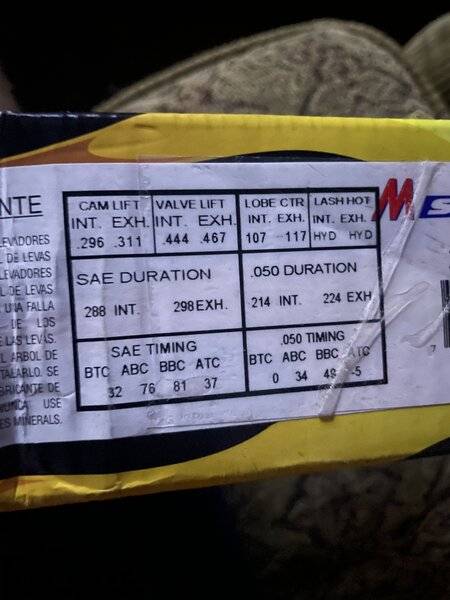

RV cam (see pic for specs)

Mopar electronic vacuum advance distributor

Mopar blue ignition box

440 source 10mm plug wires

MSD Blaster coil

Autolite #85 plugs

Full length headers with 1 3/4 primaries

Edelbrock mechanical fuel pump

New 3/8 fuel line/filter all the way to the clean tank

87 octane fuel.

I followed Holley’s instructions on setting the accelerator pump, so it starts pumping fuel as soon as the throttle is touched. I’m confused on the curb idle screw, because some say adjust it until you can barely see the transfer slots, and some say you shouldn’t be able to see them at all. I’m also confused on the sizing of the accelerator pump nozzle and diagram sizing, as some say for heavier vehicles, you need a larger one, and then some say a smaller one.

I can see fuel through the little sight glass on the sides of the bowls, it’s towards the bottom of the window.

I’ve tried tuning the idle air screws with a vacuum gauge, but that didn’t seem to help, I was able to get about 16Hg at idle. I’ve checked for vacuum leaks and don’t believe I have any.

Any input is appreciated.

Thanks, Craig.

Here’s some details.

440 big block/manual transmission

Holley 770 street avenger (single pumper)

Aluminum dual plane intake

452 iron heads

Forged aluminum pistons (9:1 compression)

RV cam (see pic for specs)

Mopar electronic vacuum advance distributor

Mopar blue ignition box

440 source 10mm plug wires

MSD Blaster coil

Autolite #85 plugs

Full length headers with 1 3/4 primaries

Edelbrock mechanical fuel pump

New 3/8 fuel line/filter all the way to the clean tank

87 octane fuel.

I followed Holley’s instructions on setting the accelerator pump, so it starts pumping fuel as soon as the throttle is touched. I’m confused on the curb idle screw, because some say adjust it until you can barely see the transfer slots, and some say you shouldn’t be able to see them at all. I’m also confused on the sizing of the accelerator pump nozzle and diagram sizing, as some say for heavier vehicles, you need a larger one, and then some say a smaller one.

I can see fuel through the little sight glass on the sides of the bowls, it’s towards the bottom of the window.

I’ve tried tuning the idle air screws with a vacuum gauge, but that didn’t seem to help, I was able to get about 16Hg at idle. I’ve checked for vacuum leaks and don’t believe I have any.

Any input is appreciated.

Thanks, Craig.