3D Prints of Hood and Door Bumper Stops with TPU 95A

I found on Sunday, rubber parts purchased a few years ago got hard and fell apart. My 66 Barracuda sits in garage, and is always ready to go. I took it for a test drive and heard slight unexpected rattles.

I purchased black TPU filament with 95A shore hardness to replace a air cleaner to cowl seal on my 25 year old tractor. It worked well without heat issues.

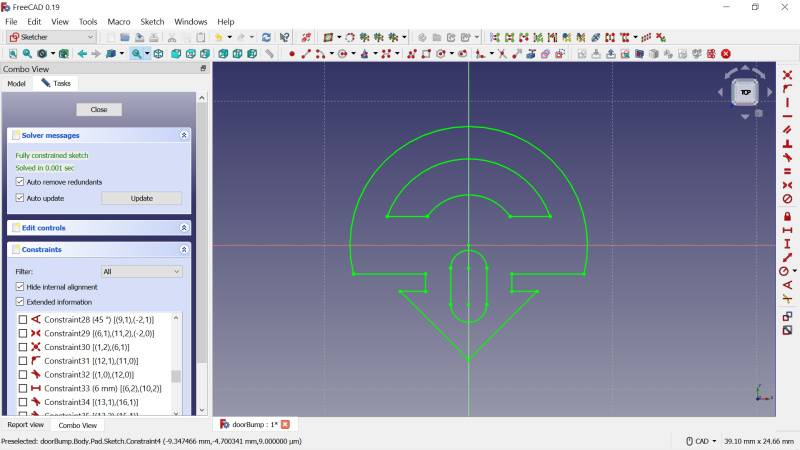

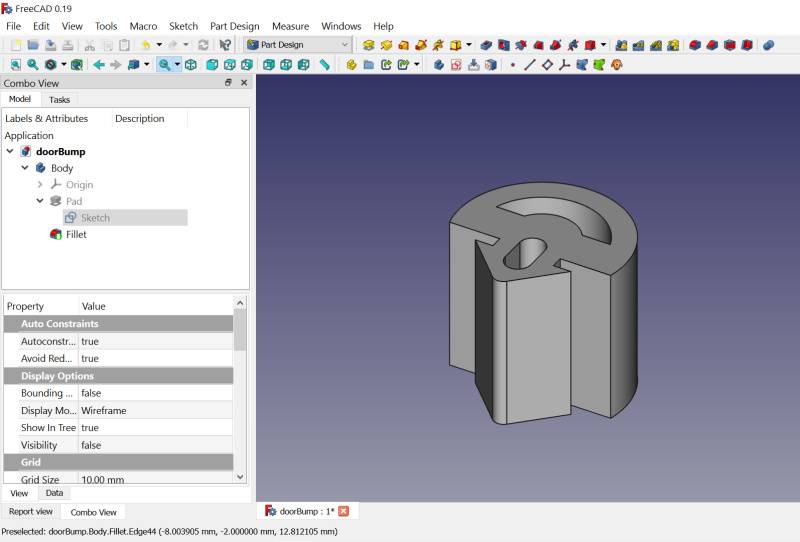

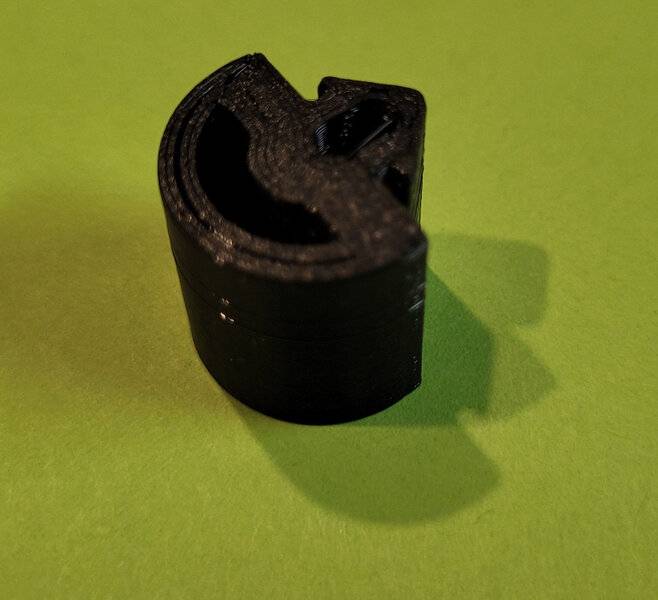

Using a digital caliper to measure example parts, started with door bumper first. I used FreeCAD to make 2D sketch in XY plane and extruded in Z, for 15mm length. I was lucky, it worked first time, so I made 3 more. TPU prints slow, at about 20 minutes per bumper.

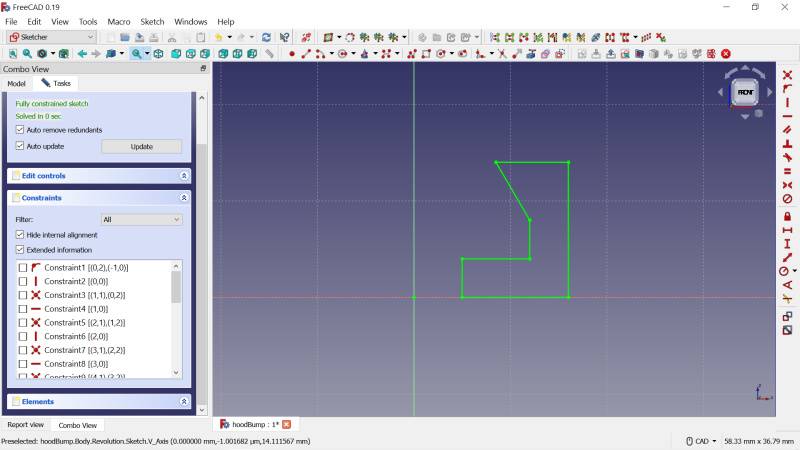

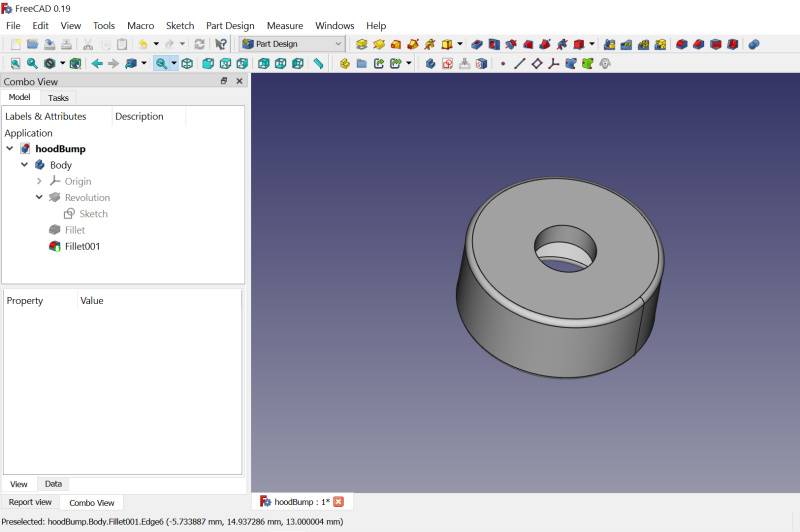

While printing door bumpers, I designed hood bumper, it was easier than door bumpers, it only took about 10 minutes. Sketch was done in XZ plane and rotated about Z axis. A hood bumper print, takes 45 minutes. Sketch is top down for print.

Printer is a Fokoos (Focus) Odin-5 F3, less than $300 printer, assembles with 4 screws.

TPU seems to print without a smell. They say the hotter you print it the harder it is. I wanted bumper to be flexible, so printed at 215C, in the mid to low range. There is infill setting, on the door bumpers 100% infill was used because design structure has that. On hood bumper 50% infill was used, and that seemed to work fine.

Pictures show design sketches, model, and finished parts. Black is hard to take pictures, please excuse that.

I found on Sunday, rubber parts purchased a few years ago got hard and fell apart. My 66 Barracuda sits in garage, and is always ready to go. I took it for a test drive and heard slight unexpected rattles.

I purchased black TPU filament with 95A shore hardness to replace a air cleaner to cowl seal on my 25 year old tractor. It worked well without heat issues.

Using a digital caliper to measure example parts, started with door bumper first. I used FreeCAD to make 2D sketch in XY plane and extruded in Z, for 15mm length. I was lucky, it worked first time, so I made 3 more. TPU prints slow, at about 20 minutes per bumper.

While printing door bumpers, I designed hood bumper, it was easier than door bumpers, it only took about 10 minutes. Sketch was done in XZ plane and rotated about Z axis. A hood bumper print, takes 45 minutes. Sketch is top down for print.

Printer is a Fokoos (Focus) Odin-5 F3, less than $300 printer, assembles with 4 screws.

TPU seems to print without a smell. They say the hotter you print it the harder it is. I wanted bumper to be flexible, so printed at 215C, in the mid to low range. There is infill setting, on the door bumpers 100% infill was used because design structure has that. On hood bumper 50% infill was used, and that seemed to work fine.

Pictures show design sketches, model, and finished parts. Black is hard to take pictures, please excuse that.