Tremec TKX first cuts

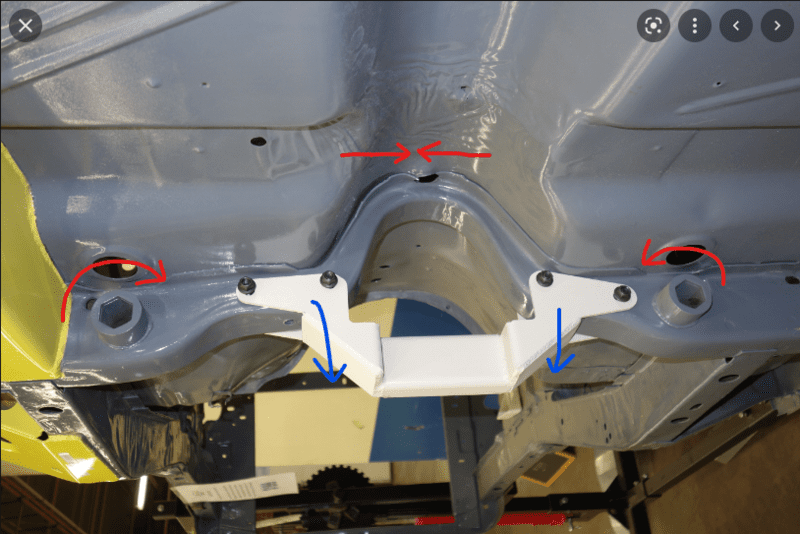

That bend in the bar is the triangulation. I've edited a picture from google to try and illustrate. The red forces at the torsion bars represent the forces that occur when your suspension compresses. The red arrows in the middle of the bend represent where those forces end up, and why that bend is important. The forces squeeze that section together; it's stable and strong. Without that upper section, you have the blue arrows showing where the forces end up. They just tug down on the floor. No matter how strong the lower section is, it's still a downward force with no counter-acting force. To be completely honest, and I hope I am not offending anybody when I say this, I don't think the folks at SST are engineers. You don't have to be one to design something like that. I do believe the folks who created the ToddRon crossmember ARE engineers - and as you can see from the cost of that unit, that's why I believe SST aren't including it. It drives up the cost and complexity.

As a mechanical engineer, I can assure you that part is important. If you can drive down the street with peace of mind without it, more power to you!

You're correct. It doesn't even have to be connected to the floor to do its job. As you can see in the pic above, it's just about dealing with the forces from the t bar movement. Tack welds are all that's needed.

That bend in the bar is the triangulation. I've edited a picture from google to try and illustrate. The red forces at the torsion bars represent the forces that occur when your suspension compresses. The red arrows in the middle of the bend represent where those forces end up, and why that bend is important. The forces squeeze that section together; it's stable and strong. Without that upper section, you have the blue arrows showing where the forces end up. They just tug down on the floor. No matter how strong the lower section is, it's still a downward force with no counter-acting force. To be completely honest, and I hope I am not offending anybody when I say this, I don't think the folks at SST are engineers. You don't have to be one to design something like that. I do believe the folks who created the ToddRon crossmember ARE engineers - and as you can see from the cost of that unit, that's why I believe SST aren't including it. It drives up the cost and complexity.

As a mechanical engineer, I can assure you that part is important. If you can drive down the street with peace of mind without it, more power to you!

You're correct. It doesn't even have to be connected to the floor to do its job. As you can see in the pic above, it's just about dealing with the forces from the t bar movement. Tack welds are all that's needed.