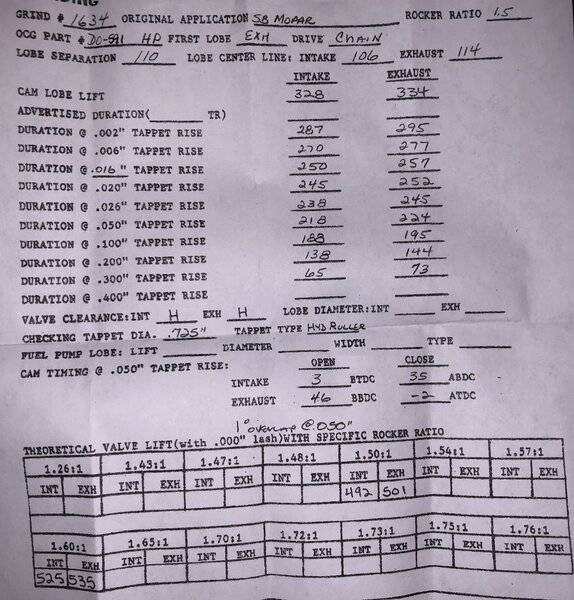

I finally got my regrind cam ordered and received from Oregon cams and I’m looking for advice on which valve springs to run with it. It’s going in a 5.9 Magnum, with speedmaster aluminum heads. Here’s the cam card. Would the Hughes 1199 kit be the kit to get? I tried calling Hughes but apparently they’re closed today.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Valve spring recommendations?

- Thread starter 75slant6

- Start date

-

Speedmaster LA heads with 11/32 stem valves?

Checking tappet diameter .725? I think you got someone else's cam card. Mopar lifters are .903 in diameter.

Yeah I asked Ken at Oregon cams if they send a spring recommendation and he said they leave that up to whoever is assembling the heads. He did say he’d recommend around a 90-100# seat pressureYou got all that info, and no spring pressure recommendation? WTF...That's pretty funny..

It’s a 5.9 magnum hydraulic roller cam, if that makes a difference.Checking tappet diameter .725? I think you got someone else's cam card. Mopar lifters are .903 in diameter.

YesSpeedmaster LA heads with 11/32 stem valves?

.903It’s a 5.9 magnum hydraulic roller cam, if that makes a difference.

I wonder if they mean the roller wheel diameter? Surely they would have made that clear. I don't know what that stock diameter is anyway. All I've ever seen referenced is the actual lifter body diameter which is .903.

.725 wheel diameter

Do you have a bare set of heads you're building or assembled? Spring selection is going to depend on your valve length and retainer installed height. According to their website (and some information I have found out by getting some of their parts in my grubby mitts) if they're assembled heads with the dual springs without dampers and "whatever" retainers they come with, they're supposed to have a 1.85 installed height with around 110 pounds of seat pressure. But if the heads are bare and you're having them set up by someone else, all they'll need to know is your targeted build lift with required seat and a ballpark open pressure.

If you come up fairly close to those parameters, this spring right here should be close to 105 pounds seat with proper retainer and locator/cup selection. You'll lose between 5 to 10 pounds of pressure during break in. When I've talked to Ken about magnum or LA spring pressure, he said that close to stock pressures worked well, but I hadn't asked him about the 270 XR grind (I am about to get one ground, ironically enough, so I'll find out about open pressures for definite...), but the profiles I had asked him about were in the same neighborhood of lift rates.

HERS084 1.437 OD, 110/1.750 FT/HR Single Valve Springs

HERS084 1.437 OD, 110/1.750 FT/HR Single Valve Springs

Last edited:

I bought a set of the bare heads but then I bought the valves from Speedmaster for those heads. So should I maybe just take the heads to the machine shop and have them measure the install height and recommend me which springs to buy?Do you have a bare set of heads you're building or assembled? Spring selection is going to depend on your valve length and retainer installed height. According to their website (and some information I have found out by getting some of their parts in my grubby mitts) if they're assembled heads with the dual springs without dampers and "whatever" retainers they come with, they're supposed to have a 1.85 installed height with around 110 pounds of seat pressure. But if the heads are bare and you're having them set up by someone else, all they'll need to know is your targeted build lift with required seat and a ballpark open pressure.

These are the intake valves I got.

Speedmaster PCE273.1049 Procomp Electronics Valves | Summit Racing

And these are the exhaust valves.

Speedmaster PCE273.1050 Procomp Electronics Valves | Summit Racing

Speedmaster PCE273.1049 Procomp Electronics Valves | Summit Racing

And these are the exhaust valves.

Speedmaster PCE273.1050 Procomp Electronics Valves | Summit Racing

The roller diam is given so that duration can be verified at the lift points on the cam card. Using a different diam roller changes the duration slightly. 110Lb seat pressure seems a little low for that cam; if it was mine, I would be aiming for 120-130.

Cuda416

Well-Known Member

If you come up fairly close to those parameters, this spring right here should be close to 105 pounds seat with proper retainer and locator/cup selection. You'll lose between 5 to 10 pounds of pressure during break in. When I've talked to Ken about magnum or LA spring pressure, he said that close to stock pressures worked well, but I hadn't asked him about the 270 XR grind (I am about to get one ground, ironically enough, so I'll find out about open pressures for definite...), but the profiles I had asked him about were in the same neighborhood of lift rates.

HERS084 1.437 OD, 110/1.750 FT/HR Single Valve Springs

holy smokes, $65 for one spring?

The parts list page that I clicked on the link from shows that it should be a set of 16.

What's wrong with the good old Hughes 1110 springs?

cookietruck

Well-Known Member

installed height is too short for the edelbrock and the knockoff heads.

cookietruck

Well-Known Member

i was looking at springs for these heads a while back.

wonder if a comp 985-16 would be ok?

the other thing i was looking at was a PAC 1218 beehive, the TFS-16918 is the same spring. just looked at prices. damn they went up quite a bit!!

wonder if a comp 985-16 would be ok?

the other thing i was looking at was a PAC 1218 beehive, the TFS-16918 is the same spring. just looked at prices. damn they went up quite a bit!!

lead69

hopeless car junkie

I would run the edelbrock 5767 springs with -.050 locks as all the spreedmasters/edelbrocks ect. seem to have around a 1.9 installed height for the spring.

Thanks for the suggestions everyone, I guess what I’m going to do is drop the heads and valves off at the machine shop and have him measure everything and give me a recommendation on springs or at least get me an install height so I can go from there.

One more question, I have a set of 1.5 ratio rockers that I’d bought because speedmaster had been out of stock on the 1.6 rockers for over a year. Well, they finally have the 1.6 back in stock for $180. Would it be worth it to buy the 1.6 arms and resell the 1.5’s that I have?

One more question, I have a set of 1.5 ratio rockers that I’d bought because speedmaster had been out of stock on the 1.6 rockers for over a year. Well, they finally have the 1.6 back in stock for $180. Would it be worth it to buy the 1.6 arms and resell the 1.5’s that I have?

cookietruck

Well-Known Member

With the hydro lifter, I’d just use the 1.5 ratio rockers

Another thing to remember about BH springs....

The SB has a short rocker & care is needed in not selecting an overly big diam spring

[ alum rockers are worse, 'cause the alum is thicker ]. You want to find this out BEFORE your machinist buys the springs. No problem here with BHs.

The SB has a short rocker & care is needed in not selecting an overly big diam spring

[ alum rockers are worse, 'cause the alum is thicker ]. You want to find this out BEFORE your machinist buys the springs. No problem here with BHs.

-