That was a special piston with a dome. The we a flat top piston Rod lower compression. With a 65 cc head and the flat top piston at a zero deck height and a .039 head gasket you’ll be at 9.8-1. If the piston sits down in the hole some, the ratio will be less. You can also use a thicker head gasket to raise the cylinder head to lower the ratio.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stroker 340>416 Build Advice

- Thread starter Psychobob22

- Start date

-

True, high compression 340 pistons were proud of the decks, your stroker package will have pistons, that unless the block is zero decked, will be some measurement down in the hole. This scenario alone, closed chamber with dished pistons vs. Open chambers with domed pistons, is much less sensitive to detonation due to better flame propagation, and less hot spots on piston faces.I wasnt specifically planning on zero decking the block but like I mentioned the machinist will have to deck a currently unknown amount to remove some gouges that are on the head surface (was there when I bought the block unfortunately).

Here comes another newbie question: based on internet search a stock 340 had a -18 deck height (the top of the piston was above the deck) when Im getting this engine built is that a value that be changed? In my head the crank and rods set that pretty much in stone based on the fact Im getting a kit.

So if I understand dynamic cr it can be used to help a higher static cr engine have less chance of detonation? So a cam with higher durations will lower dynamic cr right?

You are correct about longer durations causing less dynamic compression, lobe seperation angle also contributes to this. This is why my cams have 106LSA, to trick my engine into thinking it has a little more compression than it does, also factoring in my 3000ft elevation. The narrower LSA helps to build more cylinder pressure. This is why I suggest speaking to a cam grinder and having one tailored exactly to your combo. All of these factors will be addressed.

You are getting good advice here from guys that know a lot more than I do. I think the general theme here is buy BEST parts you can AFFORD realistically, make a plan based on expected outcome, execute the plan. All of your choices have to work together, when all parts of the build compliment one another, you will have a winning package.

Ps. Maintenance on solid flat tappet cams is very minor, and should not be a deterrent in cam choice. Not trying to sway you, just giving facts.

Last edited:

autoxcuda

Well-Known Member

- Joined

- Apr 6, 2007

- Messages

- 8,827

- Reaction score

- 3,771

He’s got power brakes. So need vacuum to run them.

Just get the compression to handle the 91 octane with a streetable cam. Tricking the motor to get by with more compression gives him a cam that will be harder to tune.

@cpearce I’m sure the setups you and your friend use work well for you guys with your experience and knowledge. But reading the O.P.’s posts, he’s a beginner to carb tuning and other advanced adjustments.

I think keeping things simple will go a long way. Someone mentioned a Edelbrock AVS carb. I can see that now being a better fit for the owner.

@Psychobob22 have you ever adjusted mechanical valves before? If not have you watched someone else do it?

Do you own a timing light and other tuning tools?

Why not get get the right compression

Just get the compression to handle the 91 octane with a streetable cam. Tricking the motor to get by with more compression gives him a cam that will be harder to tune.

@cpearce I’m sure the setups you and your friend use work well for you guys with your experience and knowledge. But reading the O.P.’s posts, he’s a beginner to carb tuning and other advanced adjustments.

I think keeping things simple will go a long way. Someone mentioned a Edelbrock AVS carb. I can see that now being a better fit for the owner.

@Psychobob22 have you ever adjusted mechanical valves before? If not have you watched someone else do it?

Do you own a timing light and other tuning tools?

Why not get get the right compression

Psychobob22

Active Member

He’s got power brakes. So need vacuum to run them.

Just get the compression to handle the 91 octane with a streetable cam. Tricking the motor to get by with more compression gives him a cam that will be harder to tune.

@cpearce I’m sure the setups you and your friend use work well for you guys with your experience and knowledge. But reading the O.P.’s posts, he’s a beginner to carb tuning and other advanced adjustments.

I think keeping things simple will go a long way. Someone mentioned a Edelbrock AVS carb. I can see that now being a better fit for the owner.

@Psychobob22 have you ever adjusted mechanical valves before? If not have you watched someone else do it?

Do you own a timing light and other tuning tools?

Why not get get the right compression

I have never adjusted valves nor seen it done. I do have a friend who is a mechanic and willing to help me with payments of beer/ammo/etc so if I dont have some skills he definitely does. So I guess assume I have medium-ish experience?

To get the lower compression that rules out the TF heads since they have the smallest chamber. Just based on all of the comments the TF heads are a better option for flow compared to the eddys unless I find someone to port them etc.

autoxcuda

Well-Known Member

- Joined

- Apr 6, 2007

- Messages

- 8,827

- Reaction score

- 3,771

I have never adjusted valves nor seen it done. I do have a friend who is a mechanic and willing to help me with payments of beer/ammo/etc so if I dont have some skills he definitely does. So I guess assume I have medium-ish experience?

To get the lower compression that rules out the TF heads since they have the smallest chamber. Just based on all of the comments the TF heads are a better option for flow compared to the eddys unless I find someone to port them etc.

I think it’s better to walk before you run.

I think a hydraulic mid 240’s @050 cam with 110 LSA would be a good fit your total situation.

I realize that BluePrint cam ran on a TV show at Westech’s Dyno in California. But driving conditions can very from a dyno for pinging. You know the as cast Edelbrock head was actually stronger under 5000 rpm than the bigger flowing Ford head.

maybe a Edelbrock head cleanup from your engine builder would be a good thing.

justinp61

Well-Known Member

- Joined

- May 15, 2009

- Messages

- 3,064

- Reaction score

- 4,051

I have never adjusted valves nor seen it done. I do have a friend who is a mechanic and willing to help me with payments of beer/ammo/etc so if I dont have some skills he definitely does. So I guess assume I have medium-ish experience?

To get the lower compression that rules out the TF heads since they have the smallest chamber. Just based on all of the comments the TF heads are a better option for flow compared to the eddys unless I find someone to port them etc.

Call Dwayne Porter and pick his brain on the cam, he can fix you up. He's PRH on this board.

Are you only hearing what you want to hear?.. there's headporting gurus on here that prefer the speedmasters over the edelbrocks... For the price of the custom rockers you'll have to use and pay for to accommodate the trick flows you could buy a complete set of speedmaster heads that will accommodate your factory rockers... If you're building a 416 pump gas street engine there's almost no way of killing north of 400 horsepower...

There's a lot of people on here that like to cyber spend other people's money and I'm not one of them...

View attachment 1715963571

My friend treed me that day and took the win but I came damn close to my dial time... There's something we say in the race forum... "Time slips don't lie".. well not my best time slip it's a good example of factory heads... Fortunately with the availability of aftermarket being so inexpensive these days it's almost easier to buy some aluminum heads already done... Just be aware of the horsepower rabbit hole you go down when you start buying expensive stuff... Now in order to take advantage of those great flowing trick flow heads you're going to need a bigger more radical cam.. and in order to take more advantage you're going to want the gears that you're not looking for in the rear end...

We all want is the best of both worlds where we can lay down a hard lick at the drag strip and have a car that smooth and easy to drive on the street...

Choose wisely grasshopper lol.....

I haven't been on much lately and then stumbled upon this thread.

Thanks for putting a smile on my face with this reply. Tony used to say pretty much this to me all the time, heck the last time we talked he was telling giving me a hard time about reading to much on the forum. "The guys on FABO like to spend other peoples money. My car with the speedmaster heads went faster than the one with the eddelbrock heads. My speedmaster rockers are the same as my prw rockers." At the end of the day his time slip was all that mattered, not what ever the newest most expensive part was. And this man had EVERY new part, old part and hard to find parts for his engines.

Last quote for the op "forget the 340, leave those for the restoration crowd. If you want to go fast and not spend as much get a 360."

I'm going to buy and build a 360 just for him. But he is still saying I'm the son he never wanted for me saying I love my 340s more.

Street/strip Demon 416, runs in our NSS brkt class. Stock J heads 2.02's, mild hyd. cam .475"int./.493 ex, don't know dur@.050, TR w/2 x 650DP's, small hdrs, locked timing@32, runs 11.5's>11.2 best on a good day max mph was 118, SS springs, 3.91's/28" Hoosiers and a hughes 3500st. shifts@5500 traps@around 6k., weight...3200@line? = 400>430fwhp.

gzig5

Well-Known Member

He’s got power brakes. So need vacuum to run them.

A hydro-boost conversion can take care of this if needed. Not free, but allows you to make less compromises on the cam selection.

Last edited:

Gearing right now it has a sure grip 3.73 741 case which I want to get a 742/489 case with probably 3.55 to get closer to highway speeds at not a ridiculous rpm and make it stronger for the higher hp engine.

Waste of money on the case unless it's the change of gears and you can find a deal. IMO. If you have to have the other cases, find one with a 3.55 set and swap the sure grip into it. The pinion thing is one of the biggest sack of BS in the mopar world.

No sense changing the pinion size unless your REALLY putting some power to it.

a 416 with a decent head on it with a XE268H will make 450+. That's a DINKY camshaft and it will be out of steam rather low in the RPM range. Maybe 5500 at best. Seen a couple do just that. Was surprised by the results. I'd keep the compression in the mid 9 range or even 9.0 to run any pump swill available. The 4 inch arm will take care of the low end power.

Being a 4 speed you can run a bigger cam with the worry of in gear idle tuning issues that an auto may have.

Being a 4 speed you can run a bigger cam with the worry of in gear idle tuning issues that an auto may have.

Being a 4 speed you can run a bigger cam with the worry of in gear idle tuning issues that an auto may have.

My favorite thing about my favorite kind of transmission.

justinp61

Well-Known Member

- Joined

- May 15, 2009

- Messages

- 3,064

- Reaction score

- 4,051

No sense changing the pinion size unless your REALLY putting some power to it.

I ran a 3.91 equipped 741 behind a pretty stout 440 in a 71 RR and never had any issues. I've seen a couple 741's break and neither broke the pinion, both broke teeth off the ring gear.

I'm with crackedback, the myth of 741's being weaker than 742's or 489's is horse ****. The smallest part of the pinion shaft is the splines and if they have the same spline count they are the same size regardless of the carrier. I'm sure someone has broken one there, but I haven't seen it.

I ran a 3.91 equipped 741 behind a pretty stout 440 in a 71 RR and never had any issues. I've seen a couple 741's break and neither broke the pinion, both broke teeth off the ring gear.

I'm with crackedback, the myth of 741's being weaker than 742's or 489's is horse ****. The smallest part of the pinion shaft is the splines and if they have the same spline count they are the same size regardless of the carrier. I'm sure someone has broken one there, but I haven't seen it.

Never broke a 741 pinion either. Broke a 489 and a 742 off at the stress riser... Driveshaft with the yoke still attached and a stub.

have spit a few teeth out the case and seen a few 4 speed 440 chargers grenade 83/4 of course to say they were abused is putting it mildly there is a reason Mopar used the Dana on big heavy 4 speed big blocks

I don’t have all the specs memorized yet but I just got my 416” stroker back from the shop last week. This is going in my 68 Dart, A518/46RH, 3:55 gears, street car that my see a couple of trips to the track later this year or next. Built to run on pump gas (91 octane). I bought the bare Trick Flow heads, Harland Sharp 1.6 roller rockers, Edelbrock Air Gap, no porting on heads or intake. Bullet cam, (Hydraulic roller). 750 Brawler carb w/ electric choke, dyno’d with Doug’s 1 5/8” headers.

What did you use for a cam? Specs?

mderoy340

Well-Known Member

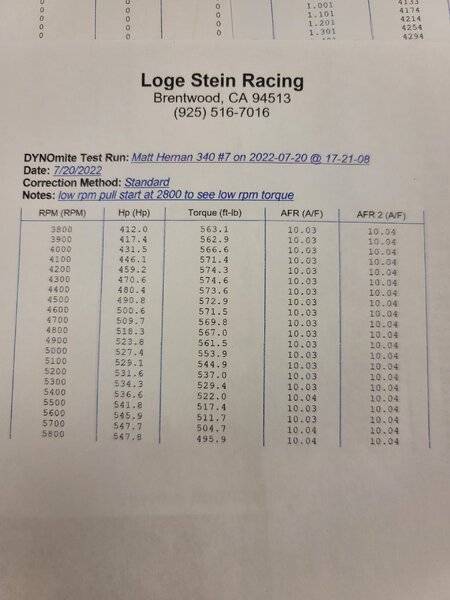

What's up with the AFR? Pig rich if that's what the motor was dynode at.I don’t have all the specs memorized yet but I just got my 416” stroker back from the shop last week. This is going in my 68 Dart, A518/46RH, 3:55 gears, street car that my see a couple of trips to the track later this year or next. Built to run on pump gas (91 octane). I bought the bare Trick Flow heads, Harland Sharp 1.6 roller rockers, Edelbrock Air Gap, no porting on heads or intake. Bullet cam, (Hydraulic roller). 750 Brawler carb w/ electric choke, dyno’d with Doug’s 1 5/8” headers.

View attachment 1715966178

Rat Bastid

Dunamis Metron

What's up with the AFR? Pig rich if that's what the motor was dynode at.

I saw that. The numbers don’t move. They ain’t right.

autoxcuda

Well-Known Member

- Joined

- Apr 6, 2007

- Messages

- 8,827

- Reaction score

- 3,771

I don’t have all the specs memorized yet but I just got my 416” stroker back from the shop last week. This is going in my 68 Dart, A518/46RH, 3:55 gears, street car that my see a couple of trips to the track later this year or next. Built to run on pump gas (91 octane). I bought the bare Trick Flow heads, Harland Sharp 1.6 roller rockers, Edelbrock Air Gap, no porting on heads or intake. Bullet cam, (Hydraulic roller). 750 Brawler carb w/ electric choke, dyno’d with Doug’s 1 5/8” headers.

View attachment 1715966178

Very impressive.

Measured compression and/or piston part number?

Details on the Bullet cam.

Psychobob22

Active Member

Very interested on what specs the cam is. What compression ratio/pistons are you running? More details please!!I don’t have all the specs memorized yet but I just got my 416” stroker back from the shop last week. This is going in my 68 Dart, A518/46RH, 3:55 gears, street car that my see a couple of trips to the track later this year or next. Built to run on pump gas (91 octane). I bought the bare Trick Flow heads, Harland Sharp 1.6 roller rockers, Edelbrock Air Gap, no porting on heads or intake. Bullet cam, (Hydraulic roller). 750 Brawler carb w/ electric choke, dyno’d with Doug’s 1 5/8” headers.

View attachment 1715966178

mopar65

Well-Known Member

the Harland sharp rockers are not the only rockers you can use with the trickflow heads. I have a 2000 360 magnum engine with the trickflow heads. The engine has a comp 550 solid lift cam and am useing PRW 1.6 Roller rockers. They are LA Rockers that allow push rod oiling. I bought the heads, rockers,rocker ratio correction kit and 3/8 th Smith Brothers push rods from Mike at B3 racing engines. This engine has been together for over 2 years and has seen 7500 rpm quite a few times. Have to get my 8 inch torque converter pulled and sent off to get restalled. But my junkyard engine in my projunkyard 91/96 dakota has ran a best so far of 7.16 at 96 mph in the 1/8 and 11.24 at 116.9 in the 1/4. I am guessing the dakota weighes around 3200/3300 with me in it and race ready. I am not sure how much hp I am making, I am guessing around 450? Which I think is pretty good, seeing how the 360 short block is all factory stock except the stock bore KB107 pistonsLet's slow down a little...

I think he might be going off of what lead69 said in an above post about Mancini roller rocker. But I don't think he meant it as mandatory, just good value.

But from the Trick Flow instruction sheet from their website:

Another important thing to note is that these heads require certain components and others are highly recommended. These parts are listed below:

1. Required: Trick Flow Specialties Head Bolt Kit (TFS-92030) or Trick Flow Specialties Head Stud Kit (TFS-61404304)

2. Required: Harland Sharp Rocker Shaft System for Magnum applications. (S72025K or S72026K)

3. Recommended: Trick Flow Specialties Rocker Shaft Stud Kit (TFS-61400613)

4. Recommended: Harland Sharp Rocker Shaft System for LA applications. (S70025K or S70026K)

-