Real World Flow Differences 2.08"/ 1.74" Valves vs 2.14"/ 1.81" Valves " Pictures Added"

All the data you need is in the intake valve's curtain area.

A larger diameter valve with dimensionally larger valve job potentially flows more mixture at any given lift point until port stall - all things being equal; i.e. no concern about shrouding, interference with exhaust valve.

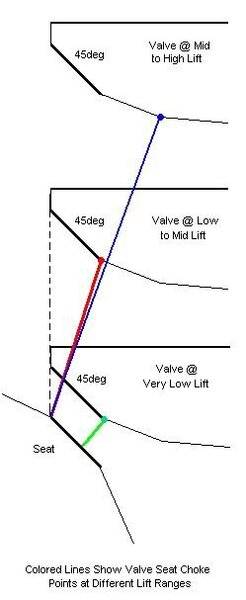

This isn't a cylinder head specific bit of data, but a universal geometric one. I brought a visual aid that should help. All you need to do is increase the diameter of the valve to see that the curtain area increases as mixture only flows around the OD of a poppet valve. If need be I can demonstrate the actual math involved. Hope this helps.

On Edit: Forget about the choke smokescreen as we are only evaluating the valve curtain area here. I should have grabbed a different graphic, but all the others I have are covered with equations.

All the data you need is in the intake valve's curtain area.

A larger diameter valve with dimensionally larger valve job potentially flows more mixture at any given lift point until port stall - all things being equal; i.e. no concern about shrouding, interference with exhaust valve.

This isn't a cylinder head specific bit of data, but a universal geometric one. I brought a visual aid that should help. All you need to do is increase the diameter of the valve to see that the curtain area increases as mixture only flows around the OD of a poppet valve. If need be I can demonstrate the actual math involved. Hope this helps.

On Edit: Forget about the choke smokescreen as we are only evaluating the valve curtain area here. I should have grabbed a different graphic, but all the others I have are covered with equations.