Eastwood Mig 90

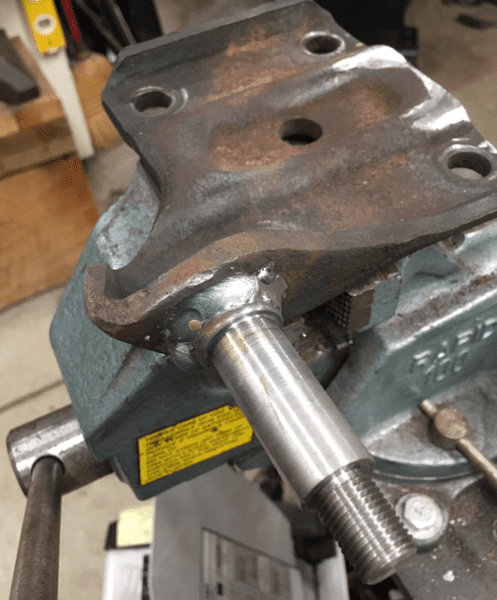

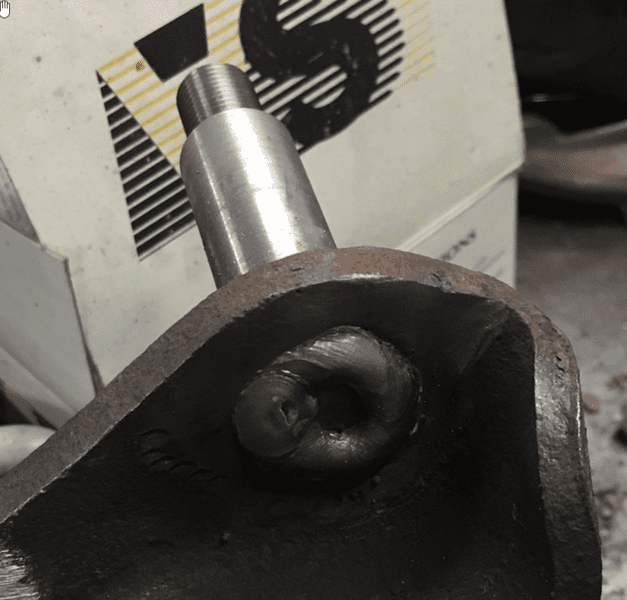

Flux core wire is going to require a LOT more clean up and grinding than solid with gas. I wouldn't consider it for body sheet metal that you care about. For structural stuff it isn't as bad. But, that machine is setup to use gas too so if you get frustrated with flux you can get a bottle and get clean welds. Understand the thickness limitations that machine has. Probably OK for 95% of the material on a car but other structural stuff bigger than 1/8" will be a problem. I think the 140Amp machines are a good sweet spot for most people, but being who I am, I went with the Hobart 190 so I have some capability for structural weldments (and it came with an aluminum spool gun). It's paid off already in being able to repair a set of lower shock mount plates rather than buy new. I wouldn't have trusted this to a 100 amp flux welder

Flux core wire is going to require a LOT more clean up and grinding than solid with gas. I wouldn't consider it for body sheet metal that you care about. For structural stuff it isn't as bad. But, that machine is setup to use gas too so if you get frustrated with flux you can get a bottle and get clean welds. Understand the thickness limitations that machine has. Probably OK for 95% of the material on a car but other structural stuff bigger than 1/8" will be a problem. I think the 140Amp machines are a good sweet spot for most people, but being who I am, I went with the Hobart 190 so I have some capability for structural weldments (and it came with an aluminum spool gun). It's paid off already in being able to repair a set of lower shock mount plates rather than buy new. I wouldn't have trusted this to a 100 amp flux welder