Dyno testing

Who would run a 7-blade, all steel, hi-attack angle, factory fan ;

without a clutch?

I run that exact fan on a thermostatic-clutch; and at 3457 pounds my lil street-367 went 93 MPH in the Eighth @900ft elevation. By the math, that is 430 hp. Ima guessing, that fan cost me nothing, even on 3 shifts, accelerating thru 4 ratios and trapping around 6150.... on a 230/237/110 cam.

but if this is right,

and the dyno engine was running a mechanical water-pump; then the pump costs

30 less 10 to 15= about 15-20hp all by itself.

Ya think there is an agenda on that show? I mean more than the obvious?

It's sorta like the anti-flat-Earthers, desperately hanging onto their opinion and ramming it down the innocents. If you watch that show often enough, yur gonna see other trickery. I put them on ignore years ago.

>One of my peeves is only publishing hp results up to the rpm of peak power. Whereas the power may hang on another 400 or 600 or even 800rpm at up to 95% of the peak. Why in the world would you shift at 5400, the peak, if you still have 95% at 5800 or 6200 or even 6600? Rev that beast!

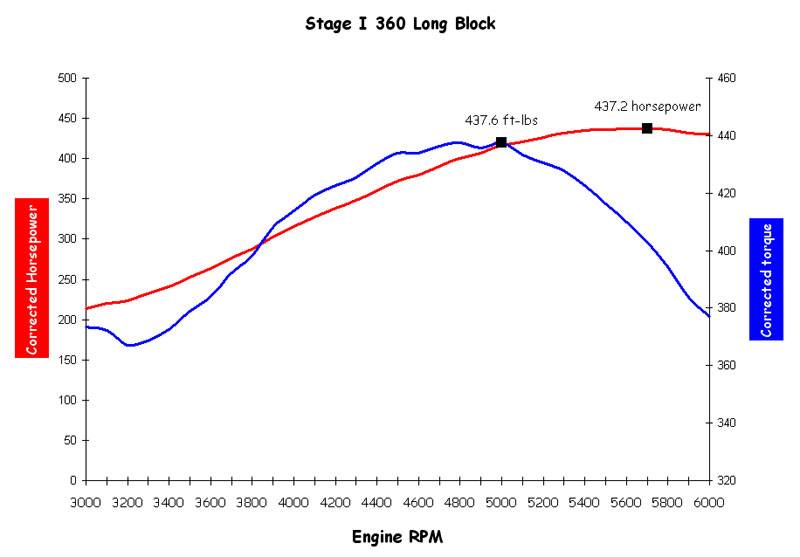

Here is one of my favorites, but from HughesPerf.; Lookit that Power peak, then extrapolate the torque curve another 200 to 400.

My guess is that;

at 6200rpm, she might still be making 355ftlbs=419hp=96% of peak.

by 6400 the Torque might be down to say 340= 415hp = 94.8%

Ima goin' to shift that at 6800 and watch the hood jump, cuz when it drops in at 5000, that is max torque right there.

Badaboom!

That's what I thought, old news.

Who would run a 7-blade, all steel, hi-attack angle, factory fan ;

without a clutch?

I run that exact fan on a thermostatic-clutch; and at 3457 pounds my lil street-367 went 93 MPH in the Eighth @900ft elevation. By the math, that is 430 hp. Ima guessing, that fan cost me nothing, even on 3 shifts, accelerating thru 4 ratios and trapping around 6150.... on a 230/237/110 cam.

but if this is right,

and the dyno engine was running a mechanical water-pump; then the pump costs

30 less 10 to 15= about 15-20hp all by itself.

Ya think there is an agenda on that show? I mean more than the obvious?

It's sorta like the anti-flat-Earthers, desperately hanging onto their opinion and ramming it down the innocents. If you watch that show often enough, yur gonna see other trickery. I put them on ignore years ago.

>One of my peeves is only publishing hp results up to the rpm of peak power. Whereas the power may hang on another 400 or 600 or even 800rpm at up to 95% of the peak. Why in the world would you shift at 5400, the peak, if you still have 95% at 5800 or 6200 or even 6600? Rev that beast!

Here is one of my favorites, but from HughesPerf.; Lookit that Power peak, then extrapolate the torque curve another 200 to 400.

My guess is that;

at 6200rpm, she might still be making 355ftlbs=419hp=96% of peak.

by 6400 the Torque might be down to say 340= 415hp = 94.8%

Ima goin' to shift that at 6800 and watch the hood jump, cuz when it drops in at 5000, that is max torque right there.

Badaboom!