68' DART BRAKE WOES

This indicates that there is air trapped in the M/C.

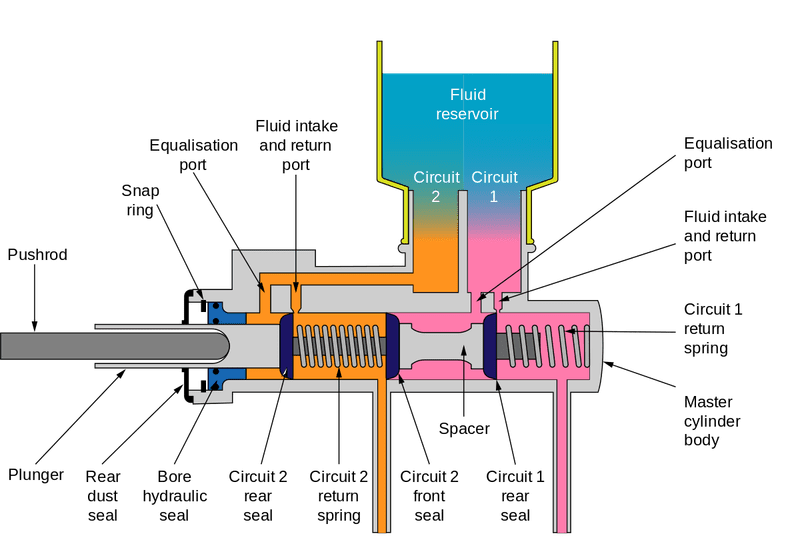

Here is a cutaway drawing of a dual M/C

As you can see, the holes are at the back of the chambers.

>If you bleed the M/C with the front up, the air cannot get out except to be pumped down to the wc's. But it's all downhill, and the air is not willing to go that way. In fact, if you were to put a clear line on it, you would see the air bubble go down on every stroke, and then rise part-ways back up as the pedal also rises.

The only way around this is to stroke continuously without pause, until it comes out of the wc's; but if you have to stop to replenish the reservoir, and the air has a clear shot upwards, it will be on it's way back up.

> So, the front of the M/C should be slightly elevated during bleeding and this should be done off the car, so you don't spend all day on the job and a gallon of fluid.

So then, as mentioned, on the bench, it is best to use clear lines so you can see if the bubbles and or the fluid, is/are just jockeying back and forth. When/if that happens, you gotta pinch the line before the up-stroke, so that the fluid cannot return backwards up the clear line..... so then the lines have to also be submerged in the fluid, so as not to draw air up from the bottom. If your M/C has working residual valves, they should be doing the pinching for you.

>Now, after you are sure you got the M/C bled, sometimes there is still a small amount of air stuck in the power chambers, right at and above the outlets; it likes to stick to chamber walls. What I now do is to elevate the rear of the M/C, and tickle the pushrod with just enough stroke to close and open the compensating ports. If there is air still trapped in there, it will now come out thru the C-ports. Keep tickling until it stops.

> with the M/C now prepped, you can bolt it back on the car, and install the lines. However, there is still a slug of air trapped in the last inch or two of the hard-lines. Do you really want to pump that all the way down to the wc's? I sure don't. So, now you need a helper to slowly push the pedal down, while the lines are slightly cracked, which allows the air to escape. But you gotta snug the fittings BEFORE the pedal goes back up; so take it slow. After two or three pumps. you should see only fluid coming out, indicating that you are done; tighten the lines securely, and check for a hard-pedal that does not sink.

> If the pedal is not hard until the second or third pump, then you need to adjust your brakes.

> If the pedal is spongy, then there is air in the system somewhere.

> if the pedal is hard but sinks over time, one of two things is wrong; 1) either you have an external leak somewhere, or 2) the M/C is defective, and fluid is escaping the power chambers inside the M/C back into the reservoirs.

> Finally, step on the pedal with mild to moderate force and keep your foot there, while you start the engine. The pedal should immediately drop at least an inch, as the booster comes on-line; this is normal.But the pedal should NOT get spongy. It may however have a different feel than without the engine running.

Take note; with New Shoes on old drums or machined drums, the curvatures of each will not likely be matched to the other. This means that the shoes will only be contacting the drums in a small window, no matter how hard you press on the pedal. And that means, until the shoes "break in", you will not be able to stop the car in the normal distance. So Don't run over anybody, or crash into something.

This break-in time can take hundreds of stops. More if you glaze the shoes by cooking them. This break-in time can be all but eliminated by having the pads ground at a brake-shop, to match the drums. I highly recommend to have this done, at least to the fronts.

Happy HotRodding.

Yur right; this is not good.

This indicates that there is air trapped in the M/C.

Here is a cutaway drawing of a dual M/C

As you can see, the holes are at the back of the chambers.

>If you bleed the M/C with the front up, the air cannot get out except to be pumped down to the wc's. But it's all downhill, and the air is not willing to go that way. In fact, if you were to put a clear line on it, you would see the air bubble go down on every stroke, and then rise part-ways back up as the pedal also rises.

The only way around this is to stroke continuously without pause, until it comes out of the wc's; but if you have to stop to replenish the reservoir, and the air has a clear shot upwards, it will be on it's way back up.

> So, the front of the M/C should be slightly elevated during bleeding and this should be done off the car, so you don't spend all day on the job and a gallon of fluid.

So then, as mentioned, on the bench, it is best to use clear lines so you can see if the bubbles and or the fluid, is/are just jockeying back and forth. When/if that happens, you gotta pinch the line before the up-stroke, so that the fluid cannot return backwards up the clear line..... so then the lines have to also be submerged in the fluid, so as not to draw air up from the bottom. If your M/C has working residual valves, they should be doing the pinching for you.

>Now, after you are sure you got the M/C bled, sometimes there is still a small amount of air stuck in the power chambers, right at and above the outlets; it likes to stick to chamber walls. What I now do is to elevate the rear of the M/C, and tickle the pushrod with just enough stroke to close and open the compensating ports. If there is air still trapped in there, it will now come out thru the C-ports. Keep tickling until it stops.

> with the M/C now prepped, you can bolt it back on the car, and install the lines. However, there is still a slug of air trapped in the last inch or two of the hard-lines. Do you really want to pump that all the way down to the wc's? I sure don't. So, now you need a helper to slowly push the pedal down, while the lines are slightly cracked, which allows the air to escape. But you gotta snug the fittings BEFORE the pedal goes back up; so take it slow. After two or three pumps. you should see only fluid coming out, indicating that you are done; tighten the lines securely, and check for a hard-pedal that does not sink.

> If the pedal is not hard until the second or third pump, then you need to adjust your brakes.

> If the pedal is spongy, then there is air in the system somewhere.

> if the pedal is hard but sinks over time, one of two things is wrong; 1) either you have an external leak somewhere, or 2) the M/C is defective, and fluid is escaping the power chambers inside the M/C back into the reservoirs.

> Finally, step on the pedal with mild to moderate force and keep your foot there, while you start the engine. The pedal should immediately drop at least an inch, as the booster comes on-line; this is normal.But the pedal should NOT get spongy. It may however have a different feel than without the engine running.

Take note; with New Shoes on old drums or machined drums, the curvatures of each will not likely be matched to the other. This means that the shoes will only be contacting the drums in a small window, no matter how hard you press on the pedal. And that means, until the shoes "break in", you will not be able to stop the car in the normal distance. So Don't run over anybody, or crash into something.

This break-in time can take hundreds of stops. More if you glaze the shoes by cooking them. This break-in time can be all but eliminated by having the pads ground at a brake-shop, to match the drums. I highly recommend to have this done, at least to the fronts.

Happy HotRodding.