66 Dart GT HT Whatsitgonnabe?

Hello folks,

I'm still around. And things are progressing, I just don't have the free time to hang around here anymore. It's a little sad, of course, with all the friends I've made on here.

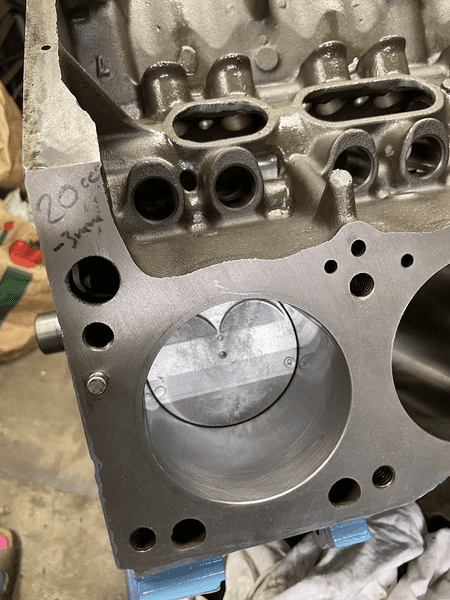

Anyway, I've got my 273 rotating assembly balanced with the cast Egge pistons and mocked up in the block.

As you can probably see, I drilled some extra flow-back holes for the oil and smoothed ot the worst casting seams.

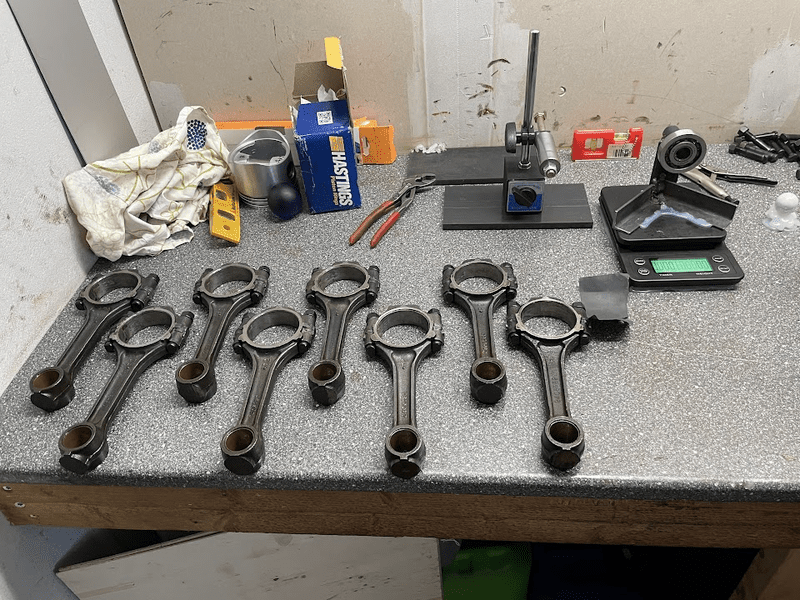

I had the machine shop weigh the lightest rod and piston and do the crank work and then I weight matched the pistons myself to save $100. NEVER doing that again. What a PITA!

I've got the rotating assembly mounted in the block temporarily. I need to get the cam in there and measure clearances. Both valve-to-piston and valve-to-cylinder wall. I've decided on a Lunati camshaft: 235/245 solid flat tappet.

I'm not sure if I dare to order pushrods before I assemble the whole thing and measure. I think it SHOULD be ok, I've got adjustable rockers and I'm using solid lifters which was originally in the engine but maybe I should wait, right? (edit: I decided to wait. Use the stock ones for mockup and measure to get the correct ones in a better material).

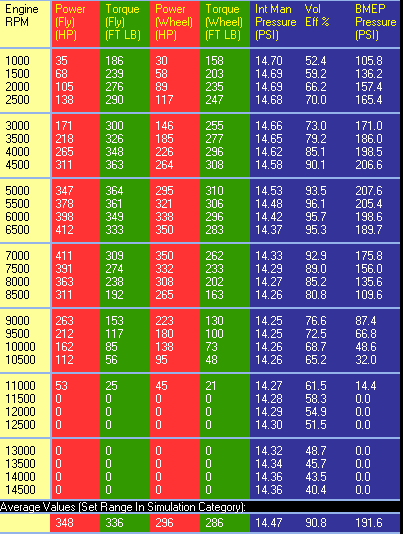

I got a copy of Desktop Dyno and some advice from a Facebok group I recently joined (yes, I'm sorry. I cheated on you guys). This cam, retarded 9 degrees gives me a power peak (412 hp (!) but I'm counting on that) at 6,500 rpm with some pretty modest assumptions like:

- Closed chamber heads

- 10.5:1 CR

- Basic port work

- 1.88/1.60 valves

- high-flow single plane intake

- Small-tube headers with mufflers

- 750 carb

The timing set I have is a Cloyes that's indexable up to 8 degrees on the crank.

So I've decided to go with the 360 heads to get the 1.88 valves and the bigger ports. I'll be welding up the chambers to get them to 59 cc or smaller. I blame This Old Tony if it goes wrong ...

If need be, I'll run E85 to be able to run the CR I need, if 10.5 isn't enough.

I'll be doing some oiling mods, too. I'm planning on drilling a new oiling hole in the mains saddle to get oil to the rods earlier in the combustion cycle, around 45 degrees after TDC, like YellowRose was discussing in the thread I mentioned above.

I've also got two pallets of engine blocks waiting for me at the Port of Gothenburg. I'll be picking them up next Wednesday when I have a few days off. Not sure where I'm going to put them all. And I need to get them sold fast. It's a lot of money ...

I'm actually selling the car itself. I've realized I'm never going to finish the paint job and put it all together so I'm going to find a car that's running and driving in stead. I actually got my wife in on it. It was more or less her idea.

We'll see what happens to the 500" but I'm leaning towards selling that, too. I didn't build it myself, which is what I really wanted to begin with. I might keep the K-frame and the 727 for it if I get another early-A. I might get a 67 and up one in stead, just to make it easier to put headers on the engine and find wheels with the 5x4.5" bolt pattern.

Anyway, that's it for now.

Hello folks,

I'm still around. And things are progressing, I just don't have the free time to hang around here anymore. It's a little sad, of course, with all the friends I've made on here.

Anyway, I've got my 273 rotating assembly balanced with the cast Egge pistons and mocked up in the block.

As you can probably see, I drilled some extra flow-back holes for the oil and smoothed ot the worst casting seams.

I had the machine shop weigh the lightest rod and piston and do the crank work and then I weight matched the pistons myself to save $100. NEVER doing that again. What a PITA!

I've got the rotating assembly mounted in the block temporarily. I need to get the cam in there and measure clearances. Both valve-to-piston and valve-to-cylinder wall. I've decided on a Lunati camshaft: 235/245 solid flat tappet.

I'm not sure if I dare to order pushrods before I assemble the whole thing and measure. I think it SHOULD be ok, I've got adjustable rockers and I'm using solid lifters which was originally in the engine but maybe I should wait, right? (edit: I decided to wait. Use the stock ones for mockup and measure to get the correct ones in a better material).

I got a copy of Desktop Dyno and some advice from a Facebok group I recently joined (yes, I'm sorry. I cheated on you guys). This cam, retarded 9 degrees gives me a power peak (412 hp (!) but I'm counting on that) at 6,500 rpm with some pretty modest assumptions like:

- Closed chamber heads

- 10.5:1 CR

- Basic port work

- 1.88/1.60 valves

- high-flow single plane intake

- Small-tube headers with mufflers

- 750 carb

The timing set I have is a Cloyes that's indexable up to 8 degrees on the crank.

So I've decided to go with the 360 heads to get the 1.88 valves and the bigger ports. I'll be welding up the chambers to get them to 59 cc or smaller. I blame This Old Tony if it goes wrong ...

If need be, I'll run E85 to be able to run the CR I need, if 10.5 isn't enough.

I'll be doing some oiling mods, too. I'm planning on drilling a new oiling hole in the mains saddle to get oil to the rods earlier in the combustion cycle, around 45 degrees after TDC, like YellowRose was discussing in the thread I mentioned above.

I've also got two pallets of engine blocks waiting for me at the Port of Gothenburg. I'll be picking them up next Wednesday when I have a few days off. Not sure where I'm going to put them all. And I need to get them sold fast. It's a lot of money ...

I'm actually selling the car itself. I've realized I'm never going to finish the paint job and put it all together so I'm going to find a car that's running and driving in stead. I actually got my wife in on it. It was more or less her idea.

We'll see what happens to the 500" but I'm leaning towards selling that, too. I didn't build it myself, which is what I really wanted to begin with. I might keep the K-frame and the 727 for it if I get another early-A. I might get a 67 and up one in stead, just to make it easier to put headers on the engine and find wheels with the 5x4.5" bolt pattern.

Anyway, that's it for now.