Axle Vent

So I ran a die down the Dr. Diff bolt (linked to in post #13), which was 7/16-20 as received. I figured the worst that could happen is that the threads would be ruined, and I would proceed with my weld-and-turn plan.

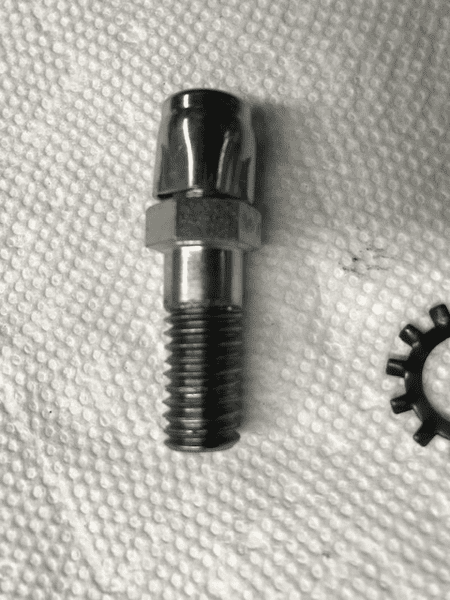

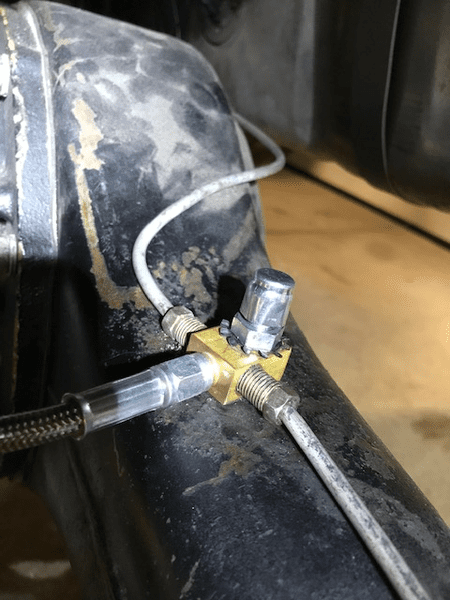

The first picture shows after I ran the die. It worked! Second shows the installed bolt.

I know myself well enough to know that I can, on occasion, overthink sumpthin. So, I un-thinked this one! (Insert back-up beeper sound.)

Thanks for the ideas, they're what got me there! Plus, if someone searches this with the same issue, here it is.

This got me thinking. Somewhere in the past, I remember something about root diameters being different for fine threads and coarse.

So I ran a die down the Dr. Diff bolt (linked to in post #13), which was 7/16-20 as received. I figured the worst that could happen is that the threads would be ruined, and I would proceed with my weld-and-turn plan.

The first picture shows after I ran the die. It worked! Second shows the installed bolt.

I know myself well enough to know that I can, on occasion, overthink sumpthin. So, I un-thinked this one! (Insert back-up beeper sound.)

Thanks for the ideas, they're what got me there! Plus, if someone searches this with the same issue, here it is.