Degreeing a Cam Shaft

I have some issues when it comes to degreeing a cam and I think I know what is wrong, but would like to ask anyway.

I have a 67 dart with a 383 that I installed a Crane Cam H-278-2. Other than that it is the stock rotating assembly, with stock iron 4 barrel and a stock 440 holley. It has TTI headers. I believe I degreed it properly before when I initially installed it. I did follow their break in procedure of running the engine at a mid range RPM for 30 minutes. That was a couple years ago. This past summer I finally got it out on the road and was trying to drive it but couldnt make it far due to the temperature climbing and if you got on it would start to back fire out the tail pipes. When I tried to put it away for the winter I had to back it up the driveway which is on a hill and it kept stalling. I finally got it in and I thought I must have screwed up installing the cam. When I tried to tune it after I got it inside I noticed there was a pretty big fuel leak and thought that must have been the issue with it stalling going up the driveway, but still wanted to check out if I degreed the cam shaft incorrectly due to the backfiring. So today while at my folks place I tried to do just that.

I got it so the drivers side rocker cover was off and the timing cover was off. I set the engine to TDC, installed a degree wheel on the crank, rotated the crank counter clockwise and installed a piston stop. I rotated the crank clockwise until it stopped. I wrote down that number. I rotated the engine counterclockwise until it hit the piston stop again, I wrote that number down. I took the difference of those two numbers, divided that by two and either added it or subtracted it so that which ever direction I rotated the engine the degree readings were the same once it hit the piston stop. Which tells me I am at TDC CORRECT!?!?!?!?

I installed a measuring device from the cam degree kit on the number one intake valve (which is on the drivers side 2nd one back from the front of the engine, RIGHT?!?!?). I left the rockers on so I would have the force from the valve springs pushing down on the lifters so I would be able to measure the .050 distance on the closing side of things. I placed the measuring rod on the portion of the rocker that is contacting the push rod. I did my best to align that measuring rod on that gauge so the center lines from both were lined up. Took awhile to do that.

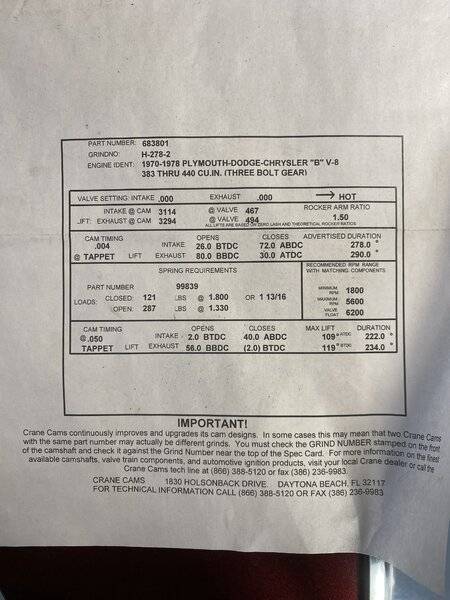

From there I rotated the engine in the clockwise direction until I saw the dial read .050 and wrote that degree down (first time was 33 ATDC). I continued rotating the engine until I saw the .050 for the last time and that was 9 ABDC. I thought to myself "damn, that is really far off" below is the cam card:

It is suppose to be at 2 BTDC at .050" open, not 33 ATDC. The timing set is a clyodes adjustable one so I set it at the 8 degrees advance, found TDC the same way as described above and re did the measurements to see when the intake was opening... it opened to .050" at 39 ATDC and closed at 14 ABDC. wrong direction so I installed the timing set at the 8 degrees retarted position, redid my TDC measurement and tried the intake opening measurements again.... it now opened at 41 degrees ATDC... needless to say I was pissed because none of this is making sense. Until I did some math....

The cam card above says I should have 222 intake duration when measuring at the .050 measurement. according to my initial measurements of opening .050 at 33 ATDC and closing to .050 at 9 ABDC I am only getting 156 degrees of duration. Am I doing my math right?!? and if so does that mean I have at least one wiped cam lobe...? I am beyond disgusted...

How do I determine if one or more cam lobes have be wiped? does that mean removing the rockers and lifters. remove the cam and take some measurements? or would there be some pretty clear indicators if something is wrong? If I do have wiped lobe(s), does that mean the entire engine needs to be disassembled...?

I have some issues when it comes to degreeing a cam and I think I know what is wrong, but would like to ask anyway.

I have a 67 dart with a 383 that I installed a Crane Cam H-278-2. Other than that it is the stock rotating assembly, with stock iron 4 barrel and a stock 440 holley. It has TTI headers. I believe I degreed it properly before when I initially installed it. I did follow their break in procedure of running the engine at a mid range RPM for 30 minutes. That was a couple years ago. This past summer I finally got it out on the road and was trying to drive it but couldnt make it far due to the temperature climbing and if you got on it would start to back fire out the tail pipes. When I tried to put it away for the winter I had to back it up the driveway which is on a hill and it kept stalling. I finally got it in and I thought I must have screwed up installing the cam. When I tried to tune it after I got it inside I noticed there was a pretty big fuel leak and thought that must have been the issue with it stalling going up the driveway, but still wanted to check out if I degreed the cam shaft incorrectly due to the backfiring. So today while at my folks place I tried to do just that.

I got it so the drivers side rocker cover was off and the timing cover was off. I set the engine to TDC, installed a degree wheel on the crank, rotated the crank counter clockwise and installed a piston stop. I rotated the crank clockwise until it stopped. I wrote down that number. I rotated the engine counterclockwise until it hit the piston stop again, I wrote that number down. I took the difference of those two numbers, divided that by two and either added it or subtracted it so that which ever direction I rotated the engine the degree readings were the same once it hit the piston stop. Which tells me I am at TDC CORRECT!?!?!?!?

I installed a measuring device from the cam degree kit on the number one intake valve (which is on the drivers side 2nd one back from the front of the engine, RIGHT?!?!?). I left the rockers on so I would have the force from the valve springs pushing down on the lifters so I would be able to measure the .050 distance on the closing side of things. I placed the measuring rod on the portion of the rocker that is contacting the push rod. I did my best to align that measuring rod on that gauge so the center lines from both were lined up. Took awhile to do that.

From there I rotated the engine in the clockwise direction until I saw the dial read .050 and wrote that degree down (first time was 33 ATDC). I continued rotating the engine until I saw the .050 for the last time and that was 9 ABDC. I thought to myself "damn, that is really far off" below is the cam card:

It is suppose to be at 2 BTDC at .050" open, not 33 ATDC. The timing set is a clyodes adjustable one so I set it at the 8 degrees advance, found TDC the same way as described above and re did the measurements to see when the intake was opening... it opened to .050" at 39 ATDC and closed at 14 ABDC. wrong direction so I installed the timing set at the 8 degrees retarted position, redid my TDC measurement and tried the intake opening measurements again.... it now opened at 41 degrees ATDC... needless to say I was pissed because none of this is making sense. Until I did some math....

The cam card above says I should have 222 intake duration when measuring at the .050 measurement. according to my initial measurements of opening .050 at 33 ATDC and closing to .050 at 9 ABDC I am only getting 156 degrees of duration. Am I doing my math right?!? and if so does that mean I have at least one wiped cam lobe...? I am beyond disgusted...

How do I determine if one or more cam lobes have be wiped? does that mean removing the rockers and lifters. remove the cam and take some measurements? or would there be some pretty clear indicators if something is wrong? If I do have wiped lobe(s), does that mean the entire engine needs to be disassembled...?