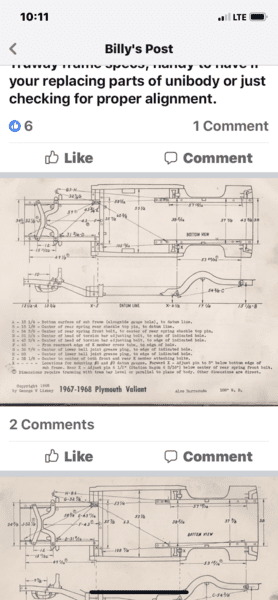

driveshaft angles

see picture with the line from front to back spring attachments. That’s the angle the housing perch is welded at so the housing-pinion is parallel to drive shaft at rest. When at rest the spring is not arched but designed to be flat when going down the road

The angle of perch on an a-body is angled down, if you set the perch level it 5 degrees UP, in other words its 5 degrees different,

see picture with the line from front to back spring attachments. That’s the angle the housing perch is welded at so the housing-pinion is parallel to drive shaft at rest. When at rest the spring is not arched but designed to be flat when going down the road