What could cause this? 360 problems ####update####

Good for setting advance on distributors too without a machine. Put a long pointer taped to rotor, twist advance, note change, multiply by 2.

Hillbilly Tools Inc.

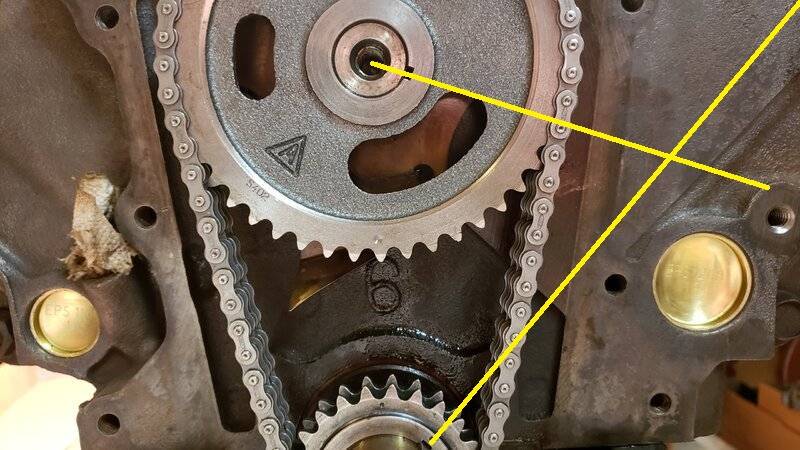

And on point with this thread. Crank keyway points inline with #1 cylinder, cam key will make a roughly 90* angle if drawing line with #1 cylinder/keyway line. If they don't intersect over there, you have an issue. Tools are CHEAP now compared to buying Starrett .001-.0001 dial indicators back in the 70-80's... $$$$

When tearing stuff down, take a dang picture to get an idea of how it should look when going back together. So much easier now than in the past when you had to sketch out stuff, like drum brake assemblies before tearing them down. Snap a photo for reference. Plenty of pics on the net for reference as well.

Good for setting advance on distributors too without a machine. Put a long pointer taped to rotor, twist advance, note change, multiply by 2.

Hillbilly Tools Inc.

And on point with this thread. Crank keyway points inline with #1 cylinder, cam key will make a roughly 90* angle if drawing line with #1 cylinder/keyway line. If they don't intersect over there, you have an issue. Tools are CHEAP now compared to buying Starrett .001-.0001 dial indicators back in the 70-80's... $$$$

When tearing stuff down, take a dang picture to get an idea of how it should look when going back together. So much easier now than in the past when you had to sketch out stuff, like drum brake assemblies before tearing them down. Snap a photo for reference. Plenty of pics on the net for reference as well.