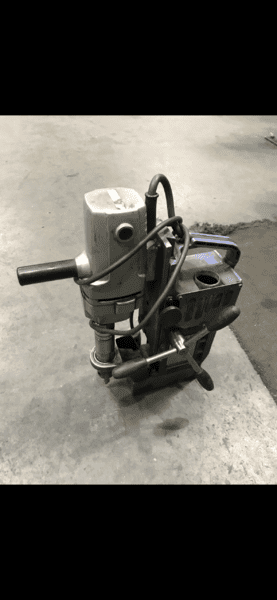

Turn a small drill press into a Bore/ Hone. Bolt it to the top of your engine block & do your own machining .

I work for a large steel fabricator. Until we acquired cnc machines, all of our holes were drilled with mag drills. Now I have 10 or so laying around collecting dust. For ***** and grins I pulled one out and measured run out on the arbor and how much free movement there was in the gibs when adjusted properly (tight enough so the head doesn’t drop by itself is the adjustment procedure). I also stuck a machinists square to the magnet and checked the surface for flatness. These are fairly expensive high quality Nitto Kohki mag drills. There was .006 runout in the arbor, .011 free movement in the gibs in the full extended position and .008 collapsed. The magnet was the definition of “not flat” there were many places I could get a .010 feeler gauge in. The fact that you are going to rely on a low quality mag drill for a procedure as accurate as honing/boring an engine block is laughable at best. Please don’t. You are not going to reinvent the wheel and find a way to accurately machine a block without machine shop level, and quality of tooling. The best case scenario is you screw up a block and manage to not hurt yourself.

I work for a large steel fabricator. Until we acquired cnc machines, all of our holes were drilled with mag drills. Now I have 10 or so laying around collecting dust. For ***** and grins I pulled one out and measured run out on the arbor and how much free movement there was in the gibs when adjusted properly (tight enough so the head doesn’t drop by itself is the adjustment procedure). I also stuck a machinists square to the magnet and checked the surface for flatness. These are fairly expensive high quality Nitto Kohki mag drills. There was .006 runout in the arbor, .011 free movement in the gibs in the full extended position and .008 collapsed. The magnet was the definition of “not flat” there were many places I could get a .010 feeler gauge in. The fact that you are going to rely on a low quality mag drill for a procedure as accurate as honing/boring an engine block is laughable at best. Please don’t. You are not going to reinvent the wheel and find a way to accurately machine a block without machine shop level, and quality of tooling. The best case scenario is you screw up a block and manage to not hurt yourself.