Distributor changes

Measure timing versus rpm from as slow as it will go to as high as you feel comfortable.

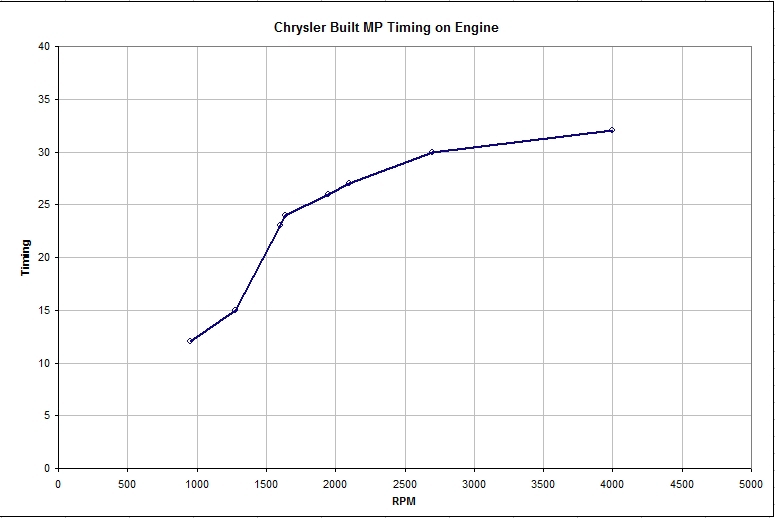

If its like the old Chrysler built ones, the curve will look something like this

Anyway, do not limit the timing to 32 at 2800 rpm. That's the reference point, thats all. Timing should continue to advance slowly with rpm for a few reasons.

The heavy spring is special because of the long loop. This delays engagement for X number of degrees allowing a quick advance, then a slower advance. In general Chrysler timing advances very quickly from idle to 1400-1800 rpm. Then advances slowly with increasing rpm.

The secret advantage of the heavy spring for high rpm when using electronic ignition.

Since you are begining with a MP distribiutor (or copy) you shouldn't have to mess much with the springs.

If you do, this thread has a good example of trialing different springs and making other adjustments.

https://www.forabodiesonly.com/mopar/threads/distributor-curve-help-needed.496183/

Yes it will vary a bit with cam, compression, heads etc. The 32* is at 2800 is a starting point that ought to be close.

As a first approximation, run it as you bought it. Install it per instructions (with vac advance plugged).

Measure timing versus rpm from as slow as it will go to as high as you feel comfortable.

If its like the old Chrysler built ones, the curve will look something like this

That's interesting. Depending on the original governor's slots begin and end, that could be so. I alsways recommend measuring the distance between the slots as well as their lengths before making any changes. Chrysler had a number of ways they could set up the curve and while it seems all those similarly stamped ought to be the same, can't be sure what you have unless you measure it.

Anyway, do not limit the timing to 32 at 2800 rpm. That's the reference point, thats all. Timing should continue to advance slowly with rpm for a few reasons.

The heavy spring is special because of the long loop. This delays engagement for X number of degrees allowing a quick advance, then a slower advance. In general Chrysler timing advances very quickly from idle to 1400-1800 rpm. Then advances slowly with increasing rpm.

The secret advantage of the heavy spring for high rpm when using electronic ignition.

Since you are begining with a MP distribiutor (or copy) you shouldn't have to mess much with the springs.

If you do, this thread has a good example of trialing different springs and making other adjustments.

https://www.forabodiesonly.com/mopar/threads/distributor-curve-help-needed.496183/

Yes.