Timing for electronic ignition upgrade

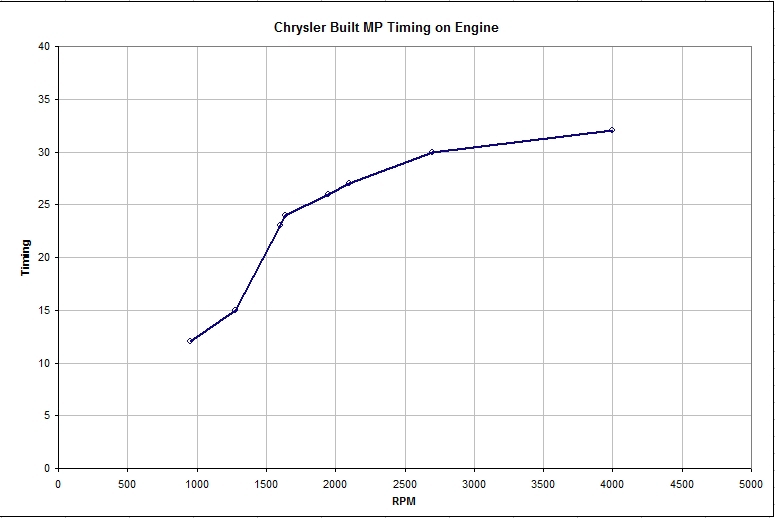

Here's another way to look at it. IF the distributor is an older Chrysler built Mopar Perfomance distributor, it will have a timing curve something like this one I measured. The advance is similar to a non-smog 273.

An initial around 12* (still at 650 rpm) would result in timing for the entire rpm range that will produce good power and work well with vacuum advance. Its basically what a non-smog 340 would have recieved if such a unicorn was ever produced.

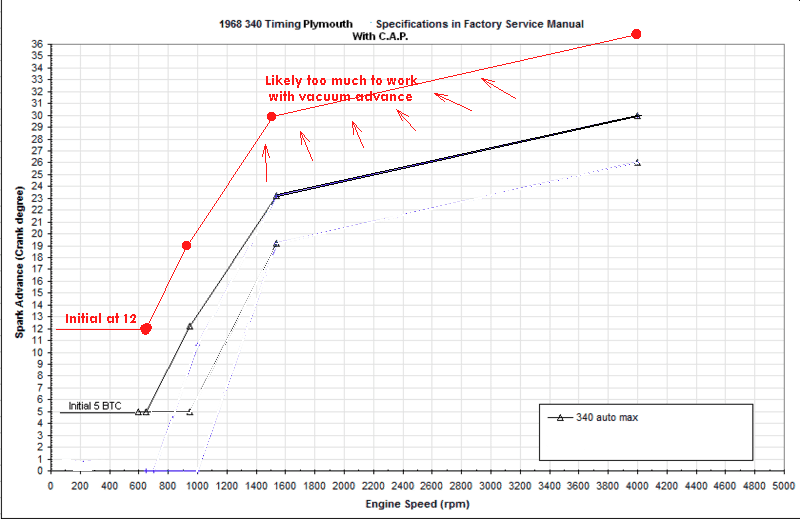

You may be asking, what happens if a long fast CAP advance is set around 12* BTC, 650 rpm?

Lets take the same factory distributor.

The answer is, depending on fuel, altitude and engine, in this example it would probably be OK or on the edge.

Except with vacuum advance and part throttle it will probably let you know its unhappy when applying light to moderate throttle between 2000 and 3000 rpm. It will ping a bit, and there may bea dead spot in the throttle, or 'trailer hitching" on the highway. Even if its OK cold, it won't be when fully heat soaked. At least that's been my experience.

Adjustments of timing within a reasonable range shouldn't need much fuel adjustment. Moer than a degree or two, or any adjustment to the throttle stop position, then yes, readjust mixture for best power.

If the engine has the original carb, check the manual. I can't recall off the top of my head which carbs had restricted fuel mix adjusment to a fairly narrow range. Some had caps or plugs on the fuel mix screws, and an adjuster on the air bleed. The idea was to allow fine tuning to meet a specified lean AFR using a CO meter. It also prevented the techs from easily attaining richer non smog idle mixes.

Here's another way to look at it. IF the distributor is an older Chrysler built Mopar Perfomance distributor, it will have a timing curve something like this one I measured. The advance is similar to a non-smog 273.

An initial around 12* (still at 650 rpm) would result in timing for the entire rpm range that will produce good power and work well with vacuum advance. Its basically what a non-smog 340 would have recieved if such a unicorn was ever produced.

You may be asking, what happens if a long fast CAP advance is set around 12* BTC, 650 rpm?

Lets take the same factory distributor.

The answer is, depending on fuel, altitude and engine, in this example it would probably be OK or on the edge.

Except with vacuum advance and part throttle it will probably let you know its unhappy when applying light to moderate throttle between 2000 and 3000 rpm. It will ping a bit, and there may bea dead spot in the throttle, or 'trailer hitching" on the highway. Even if its OK cold, it won't be when fully heat soaked. At least that's been my experience.

Adjustments of timing within a reasonable range shouldn't need much fuel adjustment. Moer than a degree or two, or any adjustment to the throttle stop position, then yes, readjust mixture for best power.

If the engine has the original carb, check the manual. I can't recall off the top of my head which carbs had restricted fuel mix adjusment to a fairly narrow range. Some had caps or plugs on the fuel mix screws, and an adjuster on the air bleed. The idea was to allow fine tuning to meet a specified lean AFR using a CO meter. It also prevented the techs from easily attaining richer non smog idle mixes.