My "new" '74 Duster- or why I need a project like a hole in the head

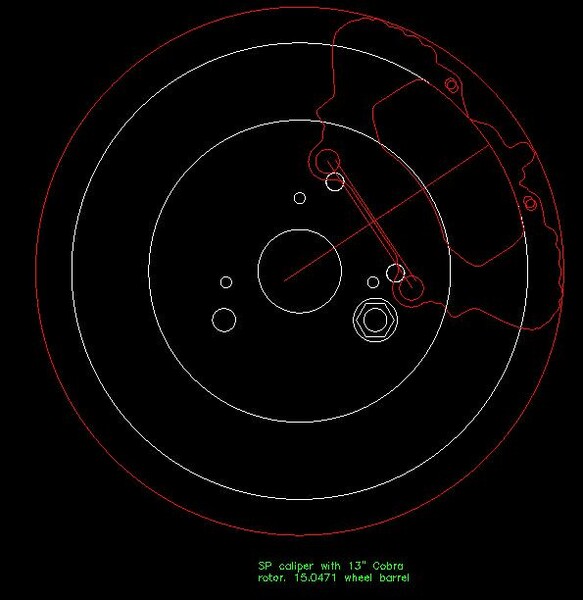

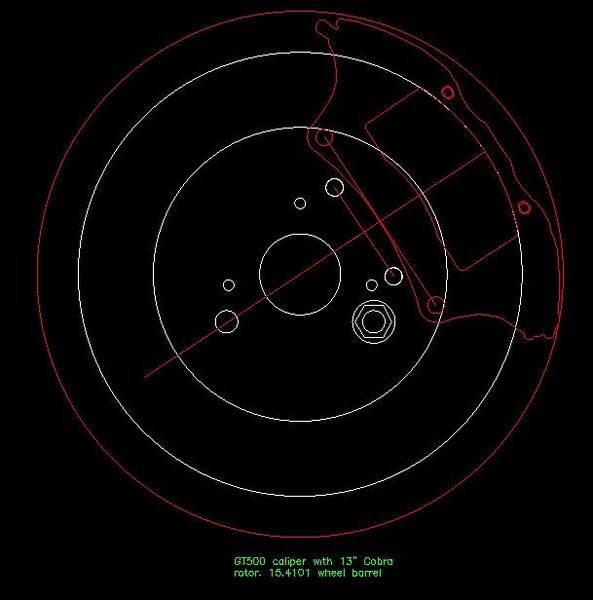

I wanted to keep a 13" rotor and 17" wheels originally. But both the Mustang and Scat Pack calipers were too big and crashed with the mounting ears on the spindle. I even tried it with drum brake spindles and couldn't make it work. The Porsche/VW caliper does look shallower, so maybe it would work? But with the SP caliper, I had to go up to 14.2" caliper to just barely get them to fit.

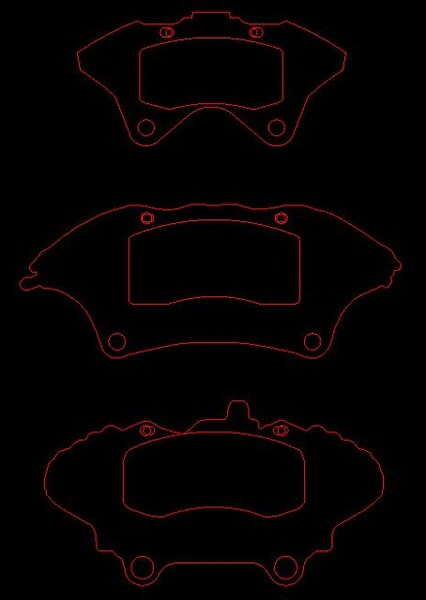

In regards to dimensions, I didn't have any initially either. I grabbed images off RockAuto that looked to be close to straight on and then traced them. Then I used the mounting hole distance to scale them. Did the same thing with a brake pad and nested them so I could get a rough idea of how they might relate to the spindle. I did have a good layout of the spindle already from when I did my C5 caliper mounts, so that helped.

This is where I started:

And then the caliper with the spindle:

These are just rough layouts to see if the idea works. I wouldn't create a mounting plate from this. But when I moved up to a 14.2" rotor, I could see that it might work, at which time I bought one caliper and a set of pads so I could take real measurements and start making a true layout.

This doesn't mean there aren't other issue that could come up. I rotated the caliper about as much as I could to get the upper hole to clear the upper spindle hole and was worried that the lower ball joint wouldn't bolt on, which is where the 3D printer came in clutch.

Sure was happy to see the clearance there. At this point, I could still return the caliper and would have only been out the cost of the pads and shipping to return the caliper. But it all seemed to check out so I went forward from there.

This is the process I used to go from no functional dimensions to metal on the table to bolt them up.

In regards to the rotor, the one Dr. Diff uses is a 32mm thick rotor, and it is really deep so it would help with wheel spokes clearing the fixed caliper. But it won't help with clearing the strut rod or sway bar on a front mount, nor the upper control arm on a rear mount.

I wanted to keep a 13" rotor and 17" wheels originally. But both the Mustang and Scat Pack calipers were too big and crashed with the mounting ears on the spindle. I even tried it with drum brake spindles and couldn't make it work. The Porsche/VW caliper does look shallower, so maybe it would work? But with the SP caliper, I had to go up to 14.2" caliper to just barely get them to fit.

In regards to dimensions, I didn't have any initially either. I grabbed images off RockAuto that looked to be close to straight on and then traced them. Then I used the mounting hole distance to scale them. Did the same thing with a brake pad and nested them so I could get a rough idea of how they might relate to the spindle. I did have a good layout of the spindle already from when I did my C5 caliper mounts, so that helped.

This is where I started:

And then the caliper with the spindle:

These are just rough layouts to see if the idea works. I wouldn't create a mounting plate from this. But when I moved up to a 14.2" rotor, I could see that it might work, at which time I bought one caliper and a set of pads so I could take real measurements and start making a true layout.

This doesn't mean there aren't other issue that could come up. I rotated the caliper about as much as I could to get the upper hole to clear the upper spindle hole and was worried that the lower ball joint wouldn't bolt on, which is where the 3D printer came in clutch.

Sure was happy to see the clearance there. At this point, I could still return the caliper and would have only been out the cost of the pads and shipping to return the caliper. But it all seemed to check out so I went forward from there.

This is the process I used to go from no functional dimensions to metal on the table to bolt them up.

In regards to the rotor, the one Dr. Diff uses is a 32mm thick rotor, and it is really deep so it would help with wheel spokes clearing the fixed caliper. But it won't help with clearing the strut rod or sway bar on a front mount, nor the upper control arm on a rear mount.