Replacement Valve Seats

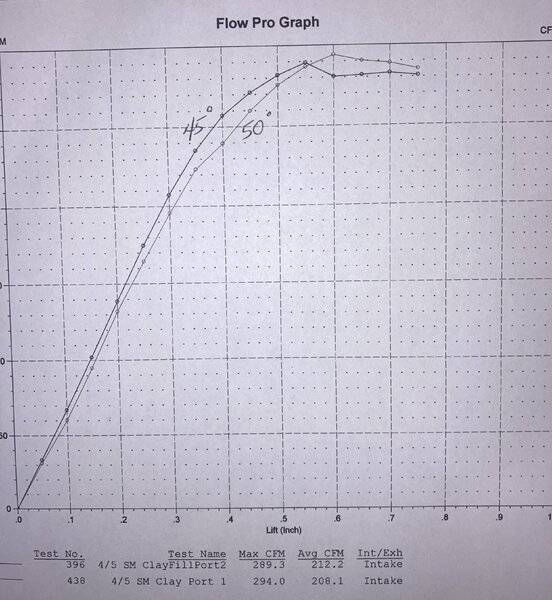

I can see something is not right more by looking at this graph than looking at the raw data. The 45 degree seat curve has a great shape until 550 lift, then the stall takes over. It can be heard earlier than 550. I know this is a common phenomenon in low port heads, but I want to understand it and fix it to the extent possible. Here are the things I've tried:

PRP - Now at 2.167 sq in and about 300 fps avg velocity. I think it is large enough.

Chamber stall - Erland Cox on Speedtalk has some good threads about flow separation starting in the chamber and working backwards up the port. I've made a lot of clay cones in the chamber and even flowed the port without a valve but with a 2" long 7 degree diverging cone built on to the port exit. No amount of chamber mods made any significant change to the flow above 600 lift.

Port CSA prior to the apex - I have increase width, but also some height prior to the apex to reduce velocity at the SSR. Now at or above 2.5 square in. Erland Cox also has some good posts about air speeding up over the short turn instead of slowing down. He makes some compelling points.

Guide boss - Fairly significant streamlining, but may still need work. There is turbulence beside the guide on the cyl center side at 280 cfm.

I have tried not to touch the throat, but with a 90.5% throat from the factory, my valve jobs have increased it to 91%+. Hence my desire to try a smaller throat. This is also part of Erland's arguments for converging over the short turn instead of diverging into a larger bowl.

I have worked some on the SSR, more on the edges than in the middle. I understand this is where the magic happens. It's also the most difficult to learn. So I've saved it for last.

I can see something is not right more by looking at this graph than looking at the raw data. The 45 degree seat curve has a great shape until 550 lift, then the stall takes over. It can be heard earlier than 550. I know this is a common phenomenon in low port heads, but I want to understand it and fix it to the extent possible. Here are the things I've tried:

PRP - Now at 2.167 sq in and about 300 fps avg velocity. I think it is large enough.

Chamber stall - Erland Cox on Speedtalk has some good threads about flow separation starting in the chamber and working backwards up the port. I've made a lot of clay cones in the chamber and even flowed the port without a valve but with a 2" long 7 degree diverging cone built on to the port exit. No amount of chamber mods made any significant change to the flow above 600 lift.

Port CSA prior to the apex - I have increase width, but also some height prior to the apex to reduce velocity at the SSR. Now at or above 2.5 square in. Erland Cox also has some good posts about air speeding up over the short turn instead of slowing down. He makes some compelling points.

Guide boss - Fairly significant streamlining, but may still need work. There is turbulence beside the guide on the cyl center side at 280 cfm.

I have tried not to touch the throat, but with a 90.5% throat from the factory, my valve jobs have increased it to 91%+. Hence my desire to try a smaller throat. This is also part of Erland's arguments for converging over the short turn instead of diverging into a larger bowl.

I have worked some on the SSR, more on the edges than in the middle. I understand this is where the magic happens. It's also the most difficult to learn. So I've saved it for last.