DOES THE HDK SUSPENSION K-MEMBER HANDLE BETTER THAN A T-BAR SUSPENSION?

@goldduster318 I can appreciate the deep investigations from your engineering mind. I'm an EE and can get down in the weeds on many topics as it pertains to electric power generation.

What would you say an average torsional spring rate is on a 1" solid sway bar? 250lbs? If so, 250lbs won't be applied to only one tab, it will be a shared load on both of them. Likely one side being pulled up and the other side being pulled down. Would it be even on each, I don't know.

The tabs are 5" long and the center of the bar is 2.25" from the crossover square tubing. From what you are saying, a 225lb load applied 2.25" from a welded corner of a U shaped bracket will bend it. I'm not a mechanical engineer, but I'm saying that $hit ain't going anywhere. So here's what I did. I put a magnetic base dial indicator on the bottom of the lower radiator square tubing (old school XV piece). The indicator was on the end of the sway bar tab. Then, using a wooden block on the sway bar itself, I jacked up the car up using the sway bar to lift the weight of the car. The block was about 4" away from the sway bar tab. I lifted the car 2.5" from its static height and the end of the tab deflected .025". I continued to lift the tire off the ground and deflection increased to .045". The indicator returned to zero when I removed the jack. My car weighs 3500lbs. I have no idea what one corner weighs, but I bet its way more than 250lbs, or even 125lbs if the loads are divided equally on the mounts. Heck, just lifting the corner 2.5" was likely way over 250lbs. Also remember I was measuring 2.75" further away than center of the bar, so likely less deflection directly under the bar. What does this prove, heck if I know, but it certainly isn't a wet noodle as some have said. FWIW, I also tried with the mag base on the bottom of the K and that resulted in only .010" at 2.5" of suspension lift. However I chose another spot to eliminate comments about the K moving with the sway bar tab. I'm sure this will que the comments about the frame twisting now since the deflection was greater when the mag base was on the lower rad support. My response to that is, it's a 50 year old car picking up one corner. I'd like to see another one that doesn't move .015"!

Next, I'll comment on the paralleling discussion. I get it, there's no triangulation, but you aren't going to see that K riding down the road without a car attached to it. Once it's bolted in, it essentially has two 16' long frame rails with a whole bunch of structure holding it square.

Do you ever sit in a bucket seat on the floor and wonder why it falls backwards? That doesn't mean its a shitty design, it just isn't being used as intended.

Lastly, reference your markup below. That rectangle plate holding the LCA tube is triangulated. There's piece on each side with the endplates as seen. The force would have to overcome the triangulation and the brackets which are designed in such a way that they slide on to the end of the tube for construction, they aren't simply butt welded, they are keyed to the square tubing. Then it would have to twist the mounting bracket that is made the same way. And lastly, the cross bar would be pushing on the other side that is obviously the same construction.

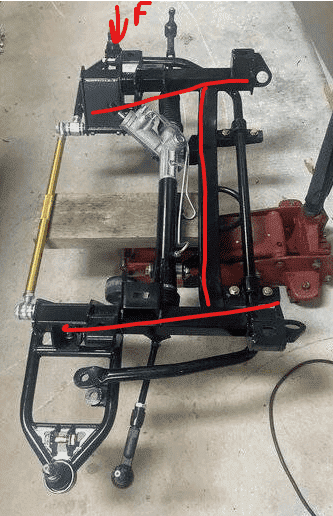

FYI. This is the current sway bar mount design, not like the one in the pictures above.

I was trying to prevent this thread to get back to the strength debate, but I'll address this and I'm done.

@goldduster318 I can appreciate the deep investigations from your engineering mind. I'm an EE and can get down in the weeds on many topics as it pertains to electric power generation.

What would you say an average torsional spring rate is on a 1" solid sway bar? 250lbs? If so, 250lbs won't be applied to only one tab, it will be a shared load on both of them. Likely one side being pulled up and the other side being pulled down. Would it be even on each, I don't know.

The tabs are 5" long and the center of the bar is 2.25" from the crossover square tubing. From what you are saying, a 225lb load applied 2.25" from a welded corner of a U shaped bracket will bend it. I'm not a mechanical engineer, but I'm saying that $hit ain't going anywhere. So here's what I did. I put a magnetic base dial indicator on the bottom of the lower radiator square tubing (old school XV piece). The indicator was on the end of the sway bar tab. Then, using a wooden block on the sway bar itself, I jacked up the car up using the sway bar to lift the weight of the car. The block was about 4" away from the sway bar tab. I lifted the car 2.5" from its static height and the end of the tab deflected .025". I continued to lift the tire off the ground and deflection increased to .045". The indicator returned to zero when I removed the jack. My car weighs 3500lbs. I have no idea what one corner weighs, but I bet its way more than 250lbs, or even 125lbs if the loads are divided equally on the mounts. Heck, just lifting the corner 2.5" was likely way over 250lbs. Also remember I was measuring 2.75" further away than center of the bar, so likely less deflection directly under the bar. What does this prove, heck if I know, but it certainly isn't a wet noodle as some have said. FWIW, I also tried with the mag base on the bottom of the K and that resulted in only .010" at 2.5" of suspension lift. However I chose another spot to eliminate comments about the K moving with the sway bar tab. I'm sure this will que the comments about the frame twisting now since the deflection was greater when the mag base was on the lower rad support. My response to that is, it's a 50 year old car picking up one corner. I'd like to see another one that doesn't move .015"!

Next, I'll comment on the paralleling discussion. I get it, there's no triangulation, but you aren't going to see that K riding down the road without a car attached to it. Once it's bolted in, it essentially has two 16' long frame rails with a whole bunch of structure holding it square.

Do you ever sit in a bucket seat on the floor and wonder why it falls backwards? That doesn't mean its a shitty design, it just isn't being used as intended.

Lastly, reference your markup below. That rectangle plate holding the LCA tube is triangulated. There's piece on each side with the endplates as seen. The force would have to overcome the triangulation and the brackets which are designed in such a way that they slide on to the end of the tube for construction, they aren't simply butt welded, they are keyed to the square tubing. Then it would have to twist the mounting bracket that is made the same way. And lastly, the cross bar would be pushing on the other side that is obviously the same construction.

FYI. This is the current sway bar mount design, not like the one in the pictures above.