DOES THE HDK SUSPENSION K-MEMBER HANDLE BETTER THAN A T-BAR SUSPENSION?

Ok, so, you think the factory didn't do finite element analysis? Of course they did. I mean, they did it long hand and with no where near the granularity that is done now, but how do you think they figured out to put spot welds say every ~2" instead of every 4"? Or what gauge of metal to use for frame rails vs K frames vs floor panels? Yes, the factory did the math.

And XV claimed they used a "million dollar program" to run the FEA on their K frame and suspension parts. Maybe that's not entirely accurate, but, they said they did FEA. None of the other suspension manufacturers for these cars have even made the claim, and I imagine if they'd done anything even marginally close to FEA they'd use it as a marking point. No reason not to.

So no, my claim isn't unsupported. XV's claim of FEA is in the article and ad, and the factory did it, because they engineered the whole damn car.

No, because welded aluminum is in fact used in modern subframes by the MILLIONS. And the XV K-frame was extruded tubing welding together, not cast, but if anything extruded aluminum makes for better welds than cast.

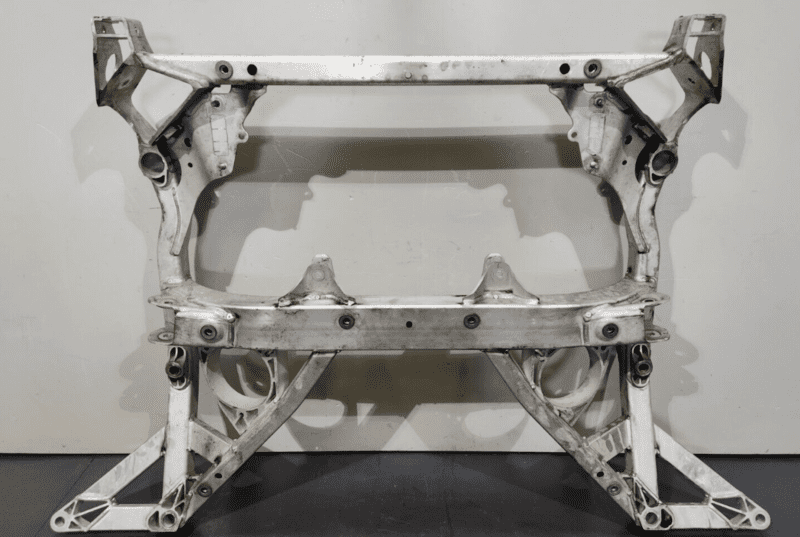

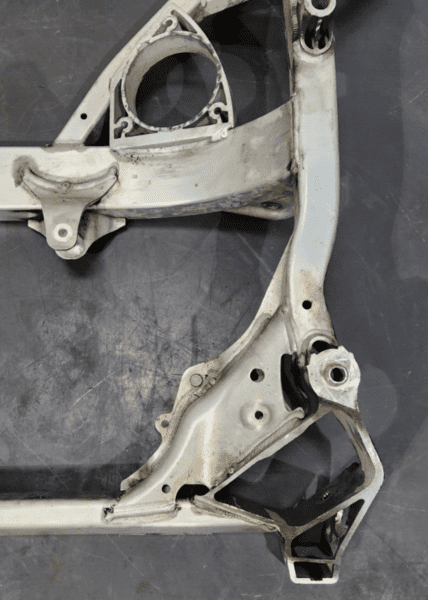

BMW's use welded aluminum K-frames. Here's a 2015-2020 M4 K frame, links included in case you want to look at even bigger pictures â 15-20 OEM BMW F80 F82 M2 M3 M4 Front Axle Support Suspension Subframe K-Frame | eBay

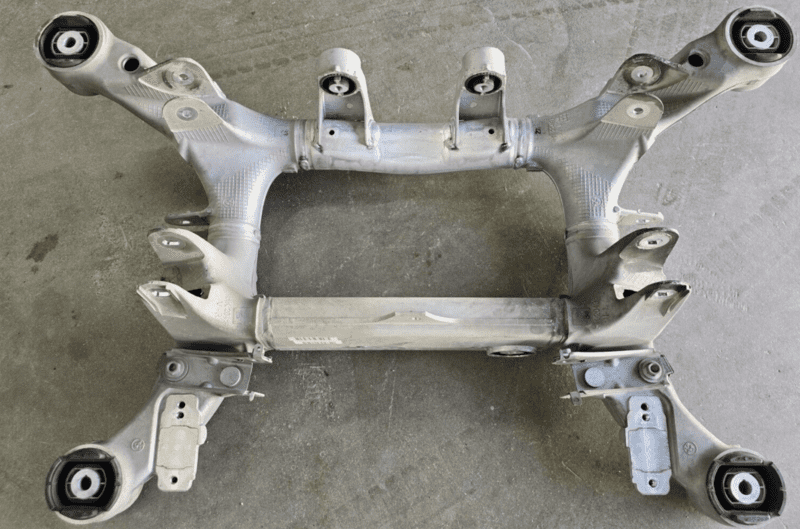

Here's a rear subframe for a 2010-2012 750 10-12 BMW 750 F02 REAR SUBFRAME SUB FRAME CROSSMEMBER CRADLE OEM GENUINE | eBay

Needless to say, welded aluminum isn't a problem for K frames or suspension pieces as long as it's properly engineered.

Seems like everything you said here is unsupported. Your memory has already been shown to be fairly inaccurate, so, let's see this prototype aluminum lower radiator support.

Ok, so, you think the factory didn't do finite element analysis? Of course they did. I mean, they did it long hand and with no where near the granularity that is done now, but how do you think they figured out to put spot welds say every ~2" instead of every 4"? Or what gauge of metal to use for frame rails vs K frames vs floor panels? Yes, the factory did the math.

And XV claimed they used a "million dollar program" to run the FEA on their K frame and suspension parts. Maybe that's not entirely accurate, but, they said they did FEA. None of the other suspension manufacturers for these cars have even made the claim, and I imagine if they'd done anything even marginally close to FEA they'd use it as a marking point. No reason not to.

So no, my claim isn't unsupported. XV's claim of FEA is in the article and ad, and the factory did it, because they engineered the whole damn car.

No, because welded aluminum is in fact used in modern subframes by the MILLIONS. And the XV K-frame was extruded tubing welding together, not cast, but if anything extruded aluminum makes for better welds than cast.

BMW's use welded aluminum K-frames. Here's a 2015-2020 M4 K frame, links included in case you want to look at even bigger pictures â 15-20 OEM BMW F80 F82 M2 M3 M4 Front Axle Support Suspension Subframe K-Frame | eBay

Here's a rear subframe for a 2010-2012 750 10-12 BMW 750 F02 REAR SUBFRAME SUB FRAME CROSSMEMBER CRADLE OEM GENUINE | eBay

Needless to say, welded aluminum isn't a problem for K frames or suspension pieces as long as it's properly engineered.

Seems like everything you said here is unsupported. Your memory has already been shown to be fairly inaccurate, so, let's see this prototype aluminum lower radiator support.