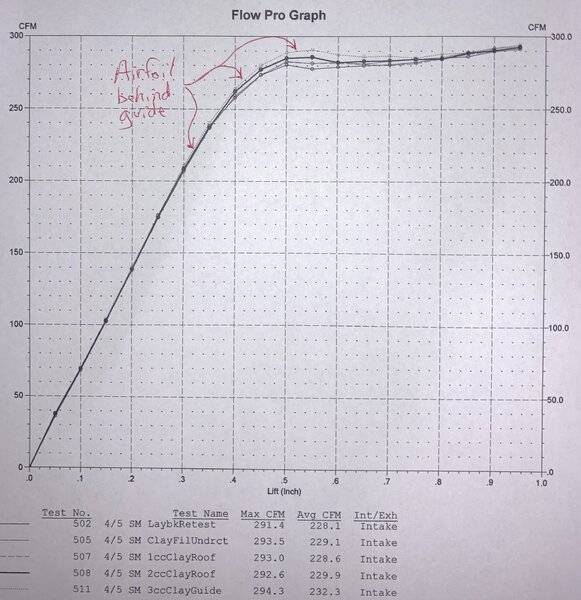

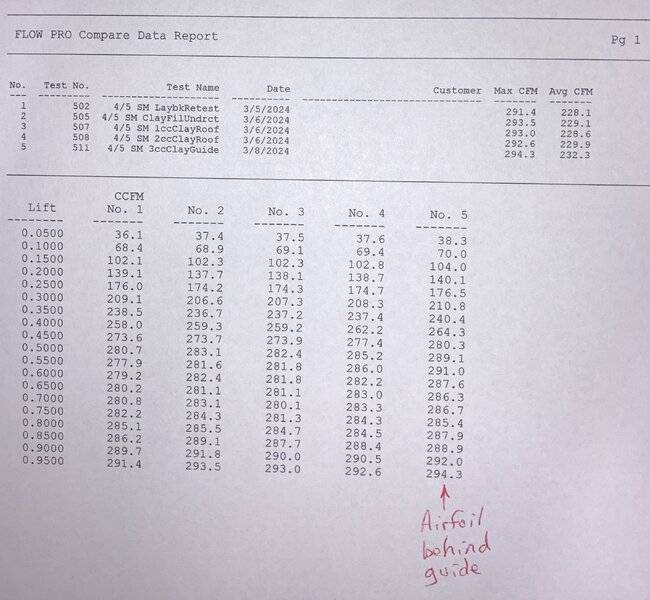

Air Flow Around Valve Guide

In the flow testing I have done, I have always been able to find some flow increases around the valve guide. Get it right and there are 10 cfm on the top end and a few cfm throughout the range. Behind the guide accounts for about half of that. I have always found a knife edge airfoil shape rotated toward bore center to be worth 3-5 cfm. I have tried many different shapes and angles and I always come back to this one. This can be seen in the picture of the abused chamber below.

Obviously this is easy to do with clay on a bench and more difficult in a running engine. I'm not suggesting this should always be done or even that the way I am showing is the correct way. Others have had great success with other methods. I am sharing the results of my testing, that's all.

In the flow testing I have done, I have always been able to find some flow increases around the valve guide. Get it right and there are 10 cfm on the top end and a few cfm throughout the range. Behind the guide accounts for about half of that. I have always found a knife edge airfoil shape rotated toward bore center to be worth 3-5 cfm. I have tried many different shapes and angles and I always come back to this one. This can be seen in the picture of the abused chamber below.

Obviously this is easy to do with clay on a bench and more difficult in a running engine. I'm not suggesting this should always be done or even that the way I am showing is the correct way. Others have had great success with other methods. I am sharing the results of my testing, that's all.