Camber Bolt Adjustment

Wow, there's A LOT going on there.

Right off the bat, yes, the loose K member bolts will make it basically impossible to align the car. Even if you did succeed somehow in getting the alignment in the right window, it would change as soon as you moved the car because the K member can move around. The K frame must be torqued to spec before any of this can proceed.

Next, the ride height appears to be pretty high. That can cause problems all by itself, the suspension geometry gets worse the higher the car is raised. The final ride height must be set before you get an alignment, because the alignment numbers change with the ride height.

The alignment shops you took the car to are incompetent. Saying things like the control arms are too short or too long suggests they don't have the foggiest idea of what they're doing. That, combined with the fact that they missed the loose K member bolts means anywhere that car has been for an alignment isn't somewhere it should ever return. And perhaps saying which shops were used will help others avoid them.

Unfortunately I do not have a shop I can recommend for an alignment anymore. I had one place that was ok because the lead tech was a circle track racer in his spare time, but he left long ago and nowadays the techs at most shops are mechanically one step above a Walmart oil change tech, and they don't trust them to remove the oil pan drain bolt anymore. So, yeah. I bought my own gear and do my own alignments now.

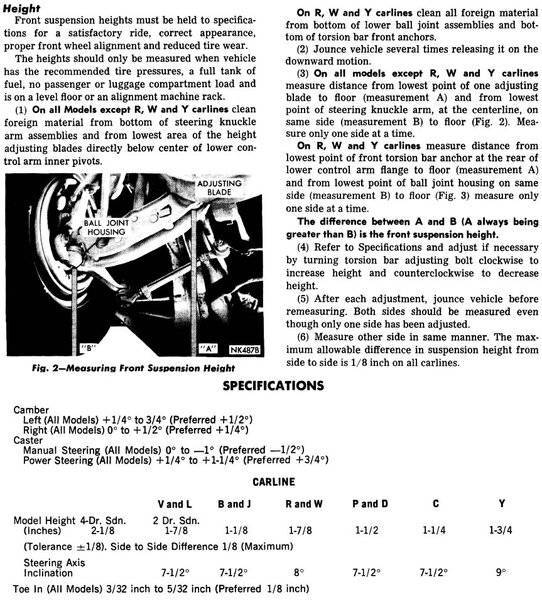

You can use this method to figure out the ride height for the car. You need to do this before you attempt another alignment. This is from the factory manual, if you don't already have one download one from here Service Manuals – MyMopar

This method should still work just fine with your QA1 parts too, by the way.

Once the K member has been torqued and the ride height set, I would loosen and re-torque the LCA pivot nuts with the car sitting on the ground. Your QA1 LCA's have rubber bushings, so they need to be tightened at ride height. And then check the torque on everything else.

After all of that has been done, you can have another go at setting a rough alignment and see what you get. With any luck it will be much closer than what you have now, which is undriveable.

Wow, there's A LOT going on there.

Right off the bat, yes, the loose K member bolts will make it basically impossible to align the car. Even if you did succeed somehow in getting the alignment in the right window, it would change as soon as you moved the car because the K member can move around. The K frame must be torqued to spec before any of this can proceed.

Next, the ride height appears to be pretty high. That can cause problems all by itself, the suspension geometry gets worse the higher the car is raised. The final ride height must be set before you get an alignment, because the alignment numbers change with the ride height.

The alignment shops you took the car to are incompetent. Saying things like the control arms are too short or too long suggests they don't have the foggiest idea of what they're doing. That, combined with the fact that they missed the loose K member bolts means anywhere that car has been for an alignment isn't somewhere it should ever return. And perhaps saying which shops were used will help others avoid them.

Unfortunately I do not have a shop I can recommend for an alignment anymore. I had one place that was ok because the lead tech was a circle track racer in his spare time, but he left long ago and nowadays the techs at most shops are mechanically one step above a Walmart oil change tech, and they don't trust them to remove the oil pan drain bolt anymore. So, yeah. I bought my own gear and do my own alignments now.

You can use this method to figure out the ride height for the car. You need to do this before you attempt another alignment. This is from the factory manual, if you don't already have one download one from here Service Manuals – MyMopar

This method should still work just fine with your QA1 parts too, by the way.

Once the K member has been torqued and the ride height set, I would loosen and re-torque the LCA pivot nuts with the car sitting on the ground. Your QA1 LCA's have rubber bushings, so they need to be tightened at ride height. And then check the torque on everything else.

After all of that has been done, you can have another go at setting a rough alignment and see what you get. With any luck it will be much closer than what you have now, which is undriveable.