1972 Dodge Colt

Long Read.

Waiting for the machine shop and the head work.

I worked on the rocker arms today doing a bunch of checking.

Here is what I found/decided.

Started with a stock rocker shaft and arms.

Stock shaft has a ground flat on the front end, top.

This places the small oiling holes on the bottom side pointing to the valve springs.

Stock Rockers

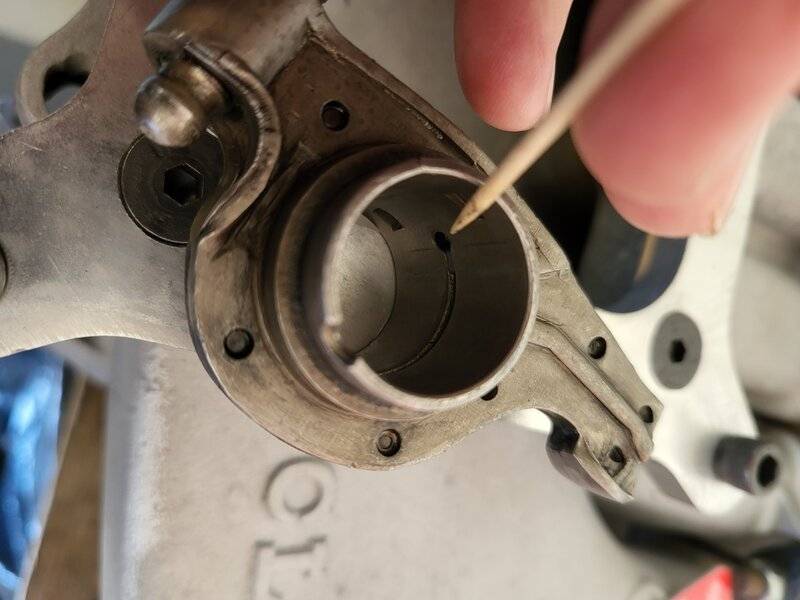

It's a little hard to see but there is a banana groove that lays over the lower oil hole.

Oil travels around and up to a small hole at the top of the inner rocker arm assembly.

Then the oil goes forward to the tip and backward to drip down the adjuster and push rod cup.

On the RAS/RAU roller rocker arms they have a similar design, just much more advanced.

And expensive.

They have a bronze bushing that is Fully Grooved.

Then there are drilled passages to the roller tip and to the adjuster and push rod cup.

Good thing about the fully grooved is you can not install the shaft wrong.

Oil will get to the right place.

You can just see the passage right behind the roller.

I am planning on using the Goodman rockers because they are 1.5 ratio.

They are not bushed.

They have one passage to oil the roller.

I have been told that the oil shaft needs to be installed upside down and backward.

This puts the oil hole up on valve side aligned with the valve stem roller.

They do not have a banana groove.

This gives a shot of oil during a portion of the rocker arm movement.

Picture above shows the oil hole position and the oil passage in the rocker.

Since it's not bushed there is a little clearance between the shaft and the rocker arm.

I assume oil flows around the inside of the rocker for lubrication.

Now when I ran the engine before I had the rocker shaft in the stock orientation.

Down and facing the valve springs.

While I knew I had oil in the shaft, I could see oil at the roller, but I had a few dry adjuster and cups.

I am concerned about this.

So, I drilled 5/64 holes in the adjuster side of the rockers to provide oil to the pushrod cups.

This is the same as the RAS/RAU 1.6 rocker arms, but without the inside groove.

If my thought process is correct, oil pressure will force oil out both holes.

Oil will also be supporting the arm on the shaft with a thin film.

When the head gets back and installed I will be very interested in seeing where the oil ends up.

Long Read.

Waiting for the machine shop and the head work.

I worked on the rocker arms today doing a bunch of checking.

Here is what I found/decided.

Started with a stock rocker shaft and arms.

Stock shaft has a ground flat on the front end, top.

This places the small oiling holes on the bottom side pointing to the valve springs.

Stock Rockers

It's a little hard to see but there is a banana groove that lays over the lower oil hole.

Oil travels around and up to a small hole at the top of the inner rocker arm assembly.

Then the oil goes forward to the tip and backward to drip down the adjuster and push rod cup.

On the RAS/RAU roller rocker arms they have a similar design, just much more advanced.

And expensive.

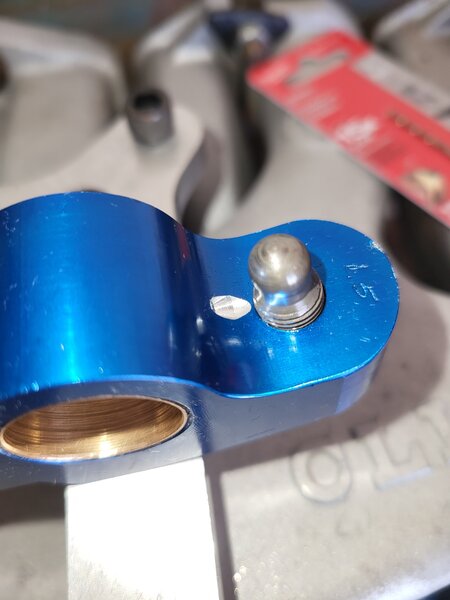

They have a bronze bushing that is Fully Grooved.

Then there are drilled passages to the roller tip and to the adjuster and push rod cup.

Good thing about the fully grooved is you can not install the shaft wrong.

Oil will get to the right place.

You can just see the passage right behind the roller.

I am planning on using the Goodman rockers because they are 1.5 ratio.

They are not bushed.

They have one passage to oil the roller.

I have been told that the oil shaft needs to be installed upside down and backward.

This puts the oil hole up on valve side aligned with the valve stem roller.

They do not have a banana groove.

This gives a shot of oil during a portion of the rocker arm movement.

Picture above shows the oil hole position and the oil passage in the rocker.

Since it's not bushed there is a little clearance between the shaft and the rocker arm.

I assume oil flows around the inside of the rocker for lubrication.

Now when I ran the engine before I had the rocker shaft in the stock orientation.

Down and facing the valve springs.

While I knew I had oil in the shaft, I could see oil at the roller, but I had a few dry adjuster and cups.

I am concerned about this.

So, I drilled 5/64 holes in the adjuster side of the rockers to provide oil to the pushrod cups.

This is the same as the RAS/RAU 1.6 rocker arms, but without the inside groove.

If my thought process is correct, oil pressure will force oil out both holes.

Oil will also be supporting the arm on the shaft with a thin film.

When the head gets back and installed I will be very interested in seeing where the oil ends up.