'68 Barracuda Formula S Fastback Restoration Background

Part Seven-- Engine

The engine is a 1970 340 that I got from a Dart that had front end damage and was sold for essentially scrap in 1977. My brother and I restored the Dart installing a rebuilt 318 which was very cheap then and sold it to a roommate in college. I kept the 340 for all these years. It was rebuilt in the late 1980’s with Sealed Power 10.5:1 pistons at 0.020 over as the bores were very clean. Almost could have just honed and re-ringed, but at that time pistons were cheap. Later I decided that I wanted to lighten the whole front of the car, so I installed Edelbrock head saving 40 lbs. The transmission was from a Dodge 2500 van with a 360. It had 4-pinion front planetary so it should be more than strong enough. Chris Andrews of Andrews Racing Transmissions built the A727 to handle 700 HP, far more than this engine will ever make.

The twin engine to this one was dyno tuned when it was in the ‘Cuda and produce 320 HP @ 5500 rpm and 360 lb-feet torque at 4400 rpm on a chassis dyno at Mile High Performance. This engine had Factory 340 X heads with port matching and bowl blending, , a Mopar Performance 284-484 cam (P4120231) solid adjustable rocker arms (273 type), Sealed Power 2332P +0.020 pistons, and an Edelbrock Performer Air-Gap manifold. The engine I installed is the same rotating assembly but with Edelbrock aluminum heads, a 280-480 cam (P4452992), and a Performer manifold replacing the Air-Gap manifold.

I don’t anticipate dyno tuning this combination, but I did have the previous 340 dyno tuned by Mile High Performance. Mile High has a chassis dyno and obtained the power/torque curve shown below. Max torque was 360 ft-lbs at 4400 RPM and max HP was 335.5 at 5500 RPM. The numbers are SAE corrected from the actual measured values per standard correction factors. As I live at 5800 feet, the loss in HP at altitude is 58. With the supposedly higher flow of the Edelbrock heads but the slightly more restrictive Performer manifold, I anticipate similar power from the 340 currently in the ‘Cuda.

The original 340 was disassembled after 30+ years of storage and thoroughly inspected. There was no rust found anywhere which is surprising as the engine was in the humid climate of Fashion Island for much of that time. I did leave the valve train loose to keep all valves closed which may have helped prevent rust. This engine will be kept in reserve as it is more valuable than the two 340’s that are spares to the ‘Cuda.

Figure 33 Chassis dyno of 340 used in 'Cuda prior to the current engine.

When I purchased the Edelbrock aluminum heads, I did not realize that they REQUIRE the use of a newer water pump which is ¾” longer than the ’69 and earlier pump. This caused the WP pully to hit the radiator electric cooling fan with the Champion radiator I planned to run. I installed the original radiator which was a 4-core desert cooler radiator I have used for 40 years and the stock fan hit that core as well. This is when I measured the Core Support placement and found it was at least 5/8” further rearward from stock most likely due to collision repair work done before I owned the car.

I located an Engineered Cooling Products 2374-S radiator with dual 10” fans (HDDF) and wiring kit. Dave Bond of Cars Remember When wired the fan controllers directly to the alternative output with the thermostatic control wires going to a single 180°F thermostatic switch. I probably will change this to a dual controlled system by adding a 195°F switch so that both fans don’t come on simultaneously.

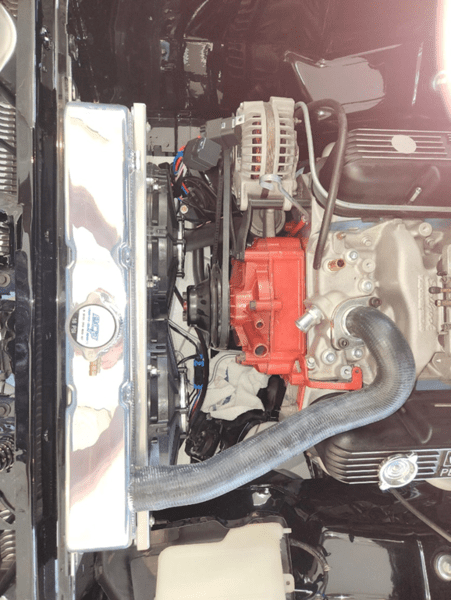

Figure 34 ECP 22" Radiator and cooling fans clearance to 340 water pump pully.

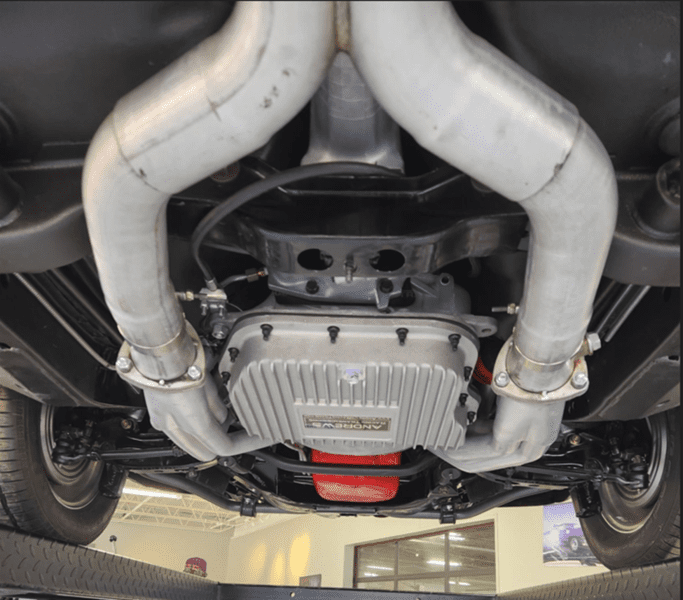

The transmission was built by Andrews Racing Transmissions of Castle Rock, Co. Chris Andrews used Kone Steels and Alto Red clutches and a red 2nd Gear band along with other premium parts. The previous transmission which I built from a ProTrans (Lancaster, CA) rebuild that never shifted properly. I wanted a trans that would shift at 6000 rpm like the stock transmission did and be firm but not harsh on the street under normal driving. Chris installed a 5400 RPM governor which should be close to what is desired. Chris recommended a cast aluminum pan with stud kit to stiffen the transmission case. Probably overkill for the HP level I have, but it does look good.

Figure 35 Transmission and exhaust installed.

Part Seven-- Engine

Engine and Transmission Details

Once the K-Frame was restored, we installed the engine/transmission on the K-Frame and lowered the body over the engine/transmission.The engine is a 1970 340 that I got from a Dart that had front end damage and was sold for essentially scrap in 1977. My brother and I restored the Dart installing a rebuilt 318 which was very cheap then and sold it to a roommate in college. I kept the 340 for all these years. It was rebuilt in the late 1980’s with Sealed Power 10.5:1 pistons at 0.020 over as the bores were very clean. Almost could have just honed and re-ringed, but at that time pistons were cheap. Later I decided that I wanted to lighten the whole front of the car, so I installed Edelbrock head saving 40 lbs. The transmission was from a Dodge 2500 van with a 360. It had 4-pinion front planetary so it should be more than strong enough. Chris Andrews of Andrews Racing Transmissions built the A727 to handle 700 HP, far more than this engine will ever make.

The twin engine to this one was dyno tuned when it was in the ‘Cuda and produce 320 HP @ 5500 rpm and 360 lb-feet torque at 4400 rpm on a chassis dyno at Mile High Performance. This engine had Factory 340 X heads with port matching and bowl blending, , a Mopar Performance 284-484 cam (P4120231) solid adjustable rocker arms (273 type), Sealed Power 2332P +0.020 pistons, and an Edelbrock Performer Air-Gap manifold. The engine I installed is the same rotating assembly but with Edelbrock aluminum heads, a 280-480 cam (P4452992), and a Performer manifold replacing the Air-Gap manifold.

I don’t anticipate dyno tuning this combination, but I did have the previous 340 dyno tuned by Mile High Performance. Mile High has a chassis dyno and obtained the power/torque curve shown below. Max torque was 360 ft-lbs at 4400 RPM and max HP was 335.5 at 5500 RPM. The numbers are SAE corrected from the actual measured values per standard correction factors. As I live at 5800 feet, the loss in HP at altitude is 58. With the supposedly higher flow of the Edelbrock heads but the slightly more restrictive Performer manifold, I anticipate similar power from the 340 currently in the ‘Cuda.

The original 340 was disassembled after 30+ years of storage and thoroughly inspected. There was no rust found anywhere which is surprising as the engine was in the humid climate of Fashion Island for much of that time. I did leave the valve train loose to keep all valves closed which may have helped prevent rust. This engine will be kept in reserve as it is more valuable than the two 340’s that are spares to the ‘Cuda.

Figure 33 Chassis dyno of 340 used in 'Cuda prior to the current engine.

When I purchased the Edelbrock aluminum heads, I did not realize that they REQUIRE the use of a newer water pump which is ¾” longer than the ’69 and earlier pump. This caused the WP pully to hit the radiator electric cooling fan with the Champion radiator I planned to run. I installed the original radiator which was a 4-core desert cooler radiator I have used for 40 years and the stock fan hit that core as well. This is when I measured the Core Support placement and found it was at least 5/8” further rearward from stock most likely due to collision repair work done before I owned the car.

I located an Engineered Cooling Products 2374-S radiator with dual 10” fans (HDDF) and wiring kit. Dave Bond of Cars Remember When wired the fan controllers directly to the alternative output with the thermostatic control wires going to a single 180°F thermostatic switch. I probably will change this to a dual controlled system by adding a 195°F switch so that both fans don’t come on simultaneously.

Figure 34 ECP 22" Radiator and cooling fans clearance to 340 water pump pully.

The transmission was built by Andrews Racing Transmissions of Castle Rock, Co. Chris Andrews used Kone Steels and Alto Red clutches and a red 2nd Gear band along with other premium parts. The previous transmission which I built from a ProTrans (Lancaster, CA) rebuild that never shifted properly. I wanted a trans that would shift at 6000 rpm like the stock transmission did and be firm but not harsh on the street under normal driving. Chris installed a 5400 RPM governor which should be close to what is desired. Chris recommended a cast aluminum pan with stud kit to stiffen the transmission case. Probably overkill for the HP level I have, but it does look good.

Figure 35 Transmission and exhaust installed.