'68 Barracuda Formula S Fastback Restoration Background

Part Eight-Wiring

We started with a square back alternator which was rebuilt to 70 amp capacity. This should be sufficient to run the headlights and cooling fans simultaneously. The original electrical wiring was left mostly unmodified but a bulkhead alternator to battery shunt with fusible link was added to protect the bulkhead connector which is a notoriously weak link in the system. The engine and alternator were also separately grounded to the chassis separate from the battery ground cable to insure that all components functioned properly. The starter used is a Durango mini-starter which was wired to the battery with new terminals and wire all obtained from Battery Cables USA (Quality Copper Battery Cables Made in the USA! - BatteryCablesUSA). We chose military grade battery terminals as they allow bolt on cables and are more durable than other options.

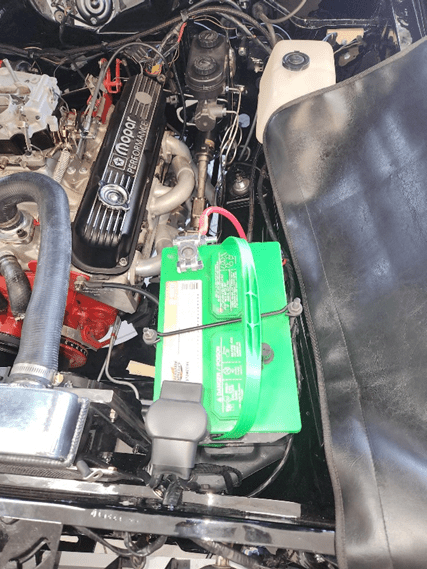

Figure 36 BatteryCableUSA.Com military grade terminals.

All connectors were attached to wires using solder plugs that match the terminal and cable connectors giving a 100% reliable connection.

Also included in the upgrading of the system was an under dash map light that I acquired from a junkyard A-Body and a Barracuda FB rear window defroster and ducting which I had from so many years ago.

Figure 37 Battery terminal wiring.

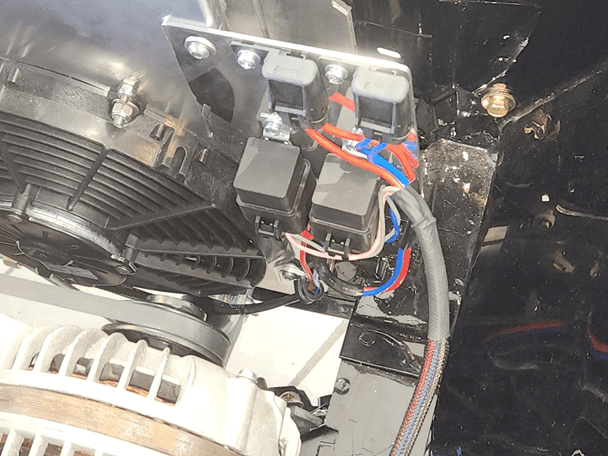

The radiator fan wiring was mounted to a plate bolted to the radiator shroud to eliminate the need to put more holes in the engine compartment sheet metal. The power is drawn from the alternator terminal as this is essentially the same as connecting to the battery. The control wiring runs to a single thermostatic switch on the intake manifold. This will be upgraded to two switches at different temperatures to reduce current draw when possible.

Figure 39 Radiator cooling fan solenoid mounting and wiring to alternator.

Part Eight-Wiring

Wiring and Upgraded Electrical Components

The Mopar electrical system works fine when stock and no modifications are made to the complete system. However, I upgraded the headlights to halogen (Marchall Ampilux) in 1977 and added headlight relays a year later, added an electric fan to help with fuel efficiency in 1978, and other minor changes over the years. During this rebuild, Dave Bond and I wanted to have a bullet proof electrical system and Dave had experience with both power and grounding improvements that he knew would work in combination with the cooling fans I chose to go with the ECP radiator.We started with a square back alternator which was rebuilt to 70 amp capacity. This should be sufficient to run the headlights and cooling fans simultaneously. The original electrical wiring was left mostly unmodified but a bulkhead alternator to battery shunt with fusible link was added to protect the bulkhead connector which is a notoriously weak link in the system. The engine and alternator were also separately grounded to the chassis separate from the battery ground cable to insure that all components functioned properly. The starter used is a Durango mini-starter which was wired to the battery with new terminals and wire all obtained from Battery Cables USA (Quality Copper Battery Cables Made in the USA! - BatteryCablesUSA). We chose military grade battery terminals as they allow bolt on cables and are more durable than other options.

Figure 36 BatteryCableUSA.Com military grade terminals.

All connectors were attached to wires using solder plugs that match the terminal and cable connectors giving a 100% reliable connection.

Also included in the upgrading of the system was an under dash map light that I acquired from a junkyard A-Body and a Barracuda FB rear window defroster and ducting which I had from so many years ago.

Figure 37 Battery terminal wiring.

The radiator fan wiring was mounted to a plate bolted to the radiator shroud to eliminate the need to put more holes in the engine compartment sheet metal. The power is drawn from the alternator terminal as this is essentially the same as connecting to the battery. The control wiring runs to a single thermostatic switch on the intake manifold. This will be upgraded to two switches at different temperatures to reduce current draw when possible.

|

Figure 39 Radiator cooling fan solenoid mounting and wiring to alternator.