HEI Conversion Question and Holley 2280 Lingering Issue

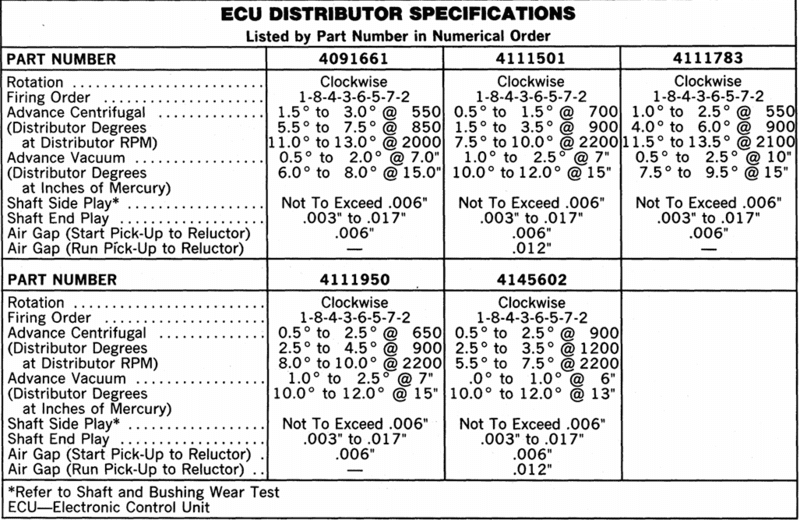

I keep seeing .008" but my 1983 manual has .006". Granted, when I checked it yesterday, it was >.010" and I've set it at .006". My truck came with the 4111950 originally.

I'll be up front that I'm definitely not a Mopar guy. I grew up messing with Fords, Jeeps, and mostly imports. So, if there is some inside knowledge about the .008" I'll set it for that. The only place I see .008" in the service manual is for a "go/no-go" check. If it's wider than that, it says to set it to .006".

That is also of course with the engine off. It's a new Chinesium dizzy, so it may be fluctuating with advance. That is something I'm not really set up to test, or at least I'm not sure how I could. Any ideas would be helpful; the manual just says to "mount in a reliable stroboscope-type distributor tester" which I would if had access to one for checking the mechanical and vacuum advance curves. I'm sure I could rig something up with a drill press, but an actual old Sun 404 or 504 would set me back more than 4 or 5 distributors. If there is a "trick" I'm all ears.

I also remember from my days as a parts-counter guy at Autozone in the 1990s (store 0499 in Gastonia, NC where the old A&P was on Franklin Blvd) when Autozone still did component testing, ignition modules were, for the most part "bad/not-bad". I do remember testing a lot of Henry's modules bad (and selling Henry's special 5.5mm socket to swap them) but The General's HEI modules seemed much more reliable. We definitely sold them, as during the 1990s the common opinion was that anything "with a brain" (Gastoniaese for "part where the magic smoke was kept", i.e. anything more advanced than a motor or solenoid) was always the problem. Additionally, the module on the vehicle is an OE GM part.

I took the truck for a drive yesterday after adjusting the reluctor gap and nothing particularly improved. I feel that it is either a wiring issue or with the distributor. At this point I'm leaning more towards the dizzy, as the misfiring seems to be more associated with acceleration. Especially off-idle and low to mid RPMs. High speed and full throttle feel smoother, but even at cruise it is somewhat noticeable, but is worse when accelerating. The truck definitely ran better with the old dizzy even though the reluctor was literally grinding into the pick-up. This three-wing clip had broken in my old distributor (not my picture) which was allowing the contact. The issue is, I found this when I was redoing the wiring, so I changed both at the same time. The HEI module and conversion was done probably close to 15K miles ago in the Summer of 2019 when I pulled the heads and changed the cam.

As for testing to see if a twisted-pair wire would improve the signal, which is likely the easiest thing for me to do, could I use a twisted pair out of a Cat5e ethernet cable as a temp test cable and if it solves the issue get a nice 18ga twisted pair with shield ordered or would the 23ga Cat5e be too small? Also, the coil wire to the distributor is routed along with the rest of the cable bundle, but it always has been since I did the HEI conversion. While the spark plug leads are standard old Packard 7mm, the coil lead is a spiral wound 8mm as I had to build it to work between the Chrysler distributor and the Ford TFI coil.

Thanks for the help so far. I know this isn't a Ramcharger/1st Gen Ram board, but I've been less than pleased with the technical discussions on the sites specifically for my truck. Y'all seem to be a much more technically competent bunch and I really do appreciate the ideas.

Also, any ideas about the carb issue? I'm positive it is something that I'm doing wrong with that as it has occurred across multiple carbs with nothing in common other than the intake they are bolted to and the person doing the bolting.

I keep seeing .008" but my 1983 manual has .006". Granted, when I checked it yesterday, it was >.010" and I've set it at .006". My truck came with the 4111950 originally.

I'll be up front that I'm definitely not a Mopar guy. I grew up messing with Fords, Jeeps, and mostly imports. So, if there is some inside knowledge about the .008" I'll set it for that. The only place I see .008" in the service manual is for a "go/no-go" check. If it's wider than that, it says to set it to .006".

That is also of course with the engine off. It's a new Chinesium dizzy, so it may be fluctuating with advance. That is something I'm not really set up to test, or at least I'm not sure how I could. Any ideas would be helpful; the manual just says to "mount in a reliable stroboscope-type distributor tester" which I would if had access to one for checking the mechanical and vacuum advance curves. I'm sure I could rig something up with a drill press, but an actual old Sun 404 or 504 would set me back more than 4 or 5 distributors. If there is a "trick" I'm all ears.

I also remember from my days as a parts-counter guy at Autozone in the 1990s (store 0499 in Gastonia, NC where the old A&P was on Franklin Blvd) when Autozone still did component testing, ignition modules were, for the most part "bad/not-bad". I do remember testing a lot of Henry's modules bad (and selling Henry's special 5.5mm socket to swap them) but The General's HEI modules seemed much more reliable. We definitely sold them, as during the 1990s the common opinion was that anything "with a brain" (Gastoniaese for "part where the magic smoke was kept", i.e. anything more advanced than a motor or solenoid) was always the problem. Additionally, the module on the vehicle is an OE GM part.

I took the truck for a drive yesterday after adjusting the reluctor gap and nothing particularly improved. I feel that it is either a wiring issue or with the distributor. At this point I'm leaning more towards the dizzy, as the misfiring seems to be more associated with acceleration. Especially off-idle and low to mid RPMs. High speed and full throttle feel smoother, but even at cruise it is somewhat noticeable, but is worse when accelerating. The truck definitely ran better with the old dizzy even though the reluctor was literally grinding into the pick-up. This three-wing clip had broken in my old distributor (not my picture) which was allowing the contact. The issue is, I found this when I was redoing the wiring, so I changed both at the same time. The HEI module and conversion was done probably close to 15K miles ago in the Summer of 2019 when I pulled the heads and changed the cam.

As for testing to see if a twisted-pair wire would improve the signal, which is likely the easiest thing for me to do, could I use a twisted pair out of a Cat5e ethernet cable as a temp test cable and if it solves the issue get a nice 18ga twisted pair with shield ordered or would the 23ga Cat5e be too small? Also, the coil wire to the distributor is routed along with the rest of the cable bundle, but it always has been since I did the HEI conversion. While the spark plug leads are standard old Packard 7mm, the coil lead is a spiral wound 8mm as I had to build it to work between the Chrysler distributor and the Ford TFI coil.

Thanks for the help so far. I know this isn't a Ramcharger/1st Gen Ram board, but I've been less than pleased with the technical discussions on the sites specifically for my truck. Y'all seem to be a much more technically competent bunch and I really do appreciate the ideas.

Also, any ideas about the carb issue? I'm positive it is something that I'm doing wrong with that as it has occurred across multiple carbs with nothing in common other than the intake they are bolted to and the person doing the bolting.