Is my cooling system operating normal?

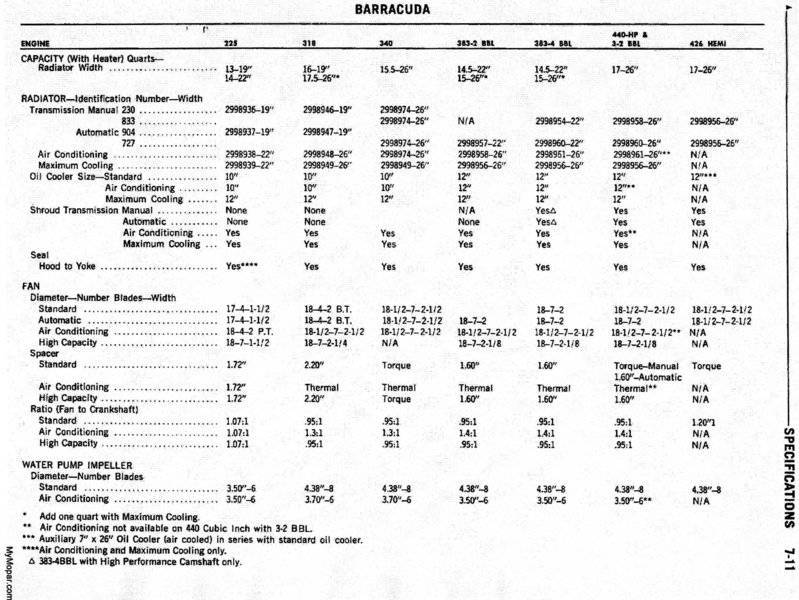

So the factory AC cars got a 6 vane water pump with a smaller impeller and were run at a pulley ratio of 1.3 or 1.4:1 depending on the engine/car etc. The non-AC cars got an 8 vane water pump with a larger impeller but a .95:1 pulley ratio. Here's the factory pulley ratio's, as well as the fan diameters, water pump impeller size and radiator sizes. You can see that for most of the applications the AC option also upsized the radiator, with a few performance engine exceptions.

Obviously I don't know for sure, but my somewhat educated guess would be that the factory wanted to move more air to cool the loads incurred from running the AC equipment more so than increase water flow. But of course with a mechanical fan you can't spin the fan faster to push more air without spinning the water pump faster too. So they sized the water pump down. But that may have had more to do with water pump cavitation because of the impeller speed than just the actual flow rate. I think it's probably assuming too much to say the flow rates stayed the same without actually seeing the GPM numbers for the pumps. It may have just been because of the pump efficiency at the higher RPM, or even the rated RPM of the pump impellers, with the larger impeller being rated for a lower peak operating RPM. I mean, if you're at 1.4:1 instead of .95:1, and you spin your engine up to 6k RPM the pump impeller goes to 8,400 rpm vs 5,700. That's a BIG jump.

Problem is most water pump manufacturers don't publish GPM vs RPM graphs. For small block applications you just get "high volume" or "low volume" and if you're lucky an impeller vane count. But you'd have to compare the GPM outputs of the pumps, and even then you'd be comparing those outputs at different engine and pump RPM's to be apples to apples.

So the factory AC cars got a 6 vane water pump with a smaller impeller and were run at a pulley ratio of 1.3 or 1.4:1 depending on the engine/car etc. The non-AC cars got an 8 vane water pump with a larger impeller but a .95:1 pulley ratio. Here's the factory pulley ratio's, as well as the fan diameters, water pump impeller size and radiator sizes. You can see that for most of the applications the AC option also upsized the radiator, with a few performance engine exceptions.

Obviously I don't know for sure, but my somewhat educated guess would be that the factory wanted to move more air to cool the loads incurred from running the AC equipment more so than increase water flow. But of course with a mechanical fan you can't spin the fan faster to push more air without spinning the water pump faster too. So they sized the water pump down. But that may have had more to do with water pump cavitation because of the impeller speed than just the actual flow rate. I think it's probably assuming too much to say the flow rates stayed the same without actually seeing the GPM numbers for the pumps. It may have just been because of the pump efficiency at the higher RPM, or even the rated RPM of the pump impellers, with the larger impeller being rated for a lower peak operating RPM. I mean, if you're at 1.4:1 instead of .95:1, and you spin your engine up to 6k RPM the pump impeller goes to 8,400 rpm vs 5,700. That's a BIG jump.

Problem is most water pump manufacturers don't publish GPM vs RPM graphs. For small block applications you just get "high volume" or "low volume" and if you're lucky an impeller vane count. But you'd have to compare the GPM outputs of the pumps, and even then you'd be comparing those outputs at different engine and pump RPM's to be apples to apples.