Little $250 69 Valiant

Hey guys. Well I have spoken to my friend thats doing my gauge faces and its gonna be a few more weeks til I get them back so I decided while I have it apart, I may as well do a mod I seen a LONG time ago from Mopar Action magazine.

In the August 2000 Issue there is a write up on how to make your gauge cluster have stable needles! I have a bunch of old Mopar mags from when I was in the Navy on cruise. I just kept gettin' em' and collecting a little knowledge along the way.

Anyhow I thought Id transfer and summerize the procedure for anyone who hasnt seen this yet.

Here we go!

So here is the list of items they say you need.

1. A new regulator known as the "7805" in electronics world. (its the 3 pronged item) Got it from Radio Shack for less than a buck!

2. A small electrolytic capacitor. (the little barrel thing) Any value from 5-100uF. It must have a voltage rating of atleast 15 volts (more is fine) Mine as was the one in the magazine was a 10uF @ 100V. "Not critical" they say!

3. You need a heat sink to cool down the new regulator. I couldnt find one at Radio Shack so I made one from a strip of aluminum. I know from experiance with other things that these little buggers get really warm!

4. You need 3 pieces of wire anywhere from 20-26 gauge to tie all the components together.

NOTE: I bought the compund that helps to transfer thermal energy (heat) so that my home made heat sink may perform a little better. They say nothing about it in the artical.

Here is how this works: the regulator lets only a steady 5 volts go out, and the capacitor keeps any spikes from getting to the guages, so its somewhat like double protection there. Anyhow with all of this being better more reliable technology, it makes our old Mopars have some reliable readings!

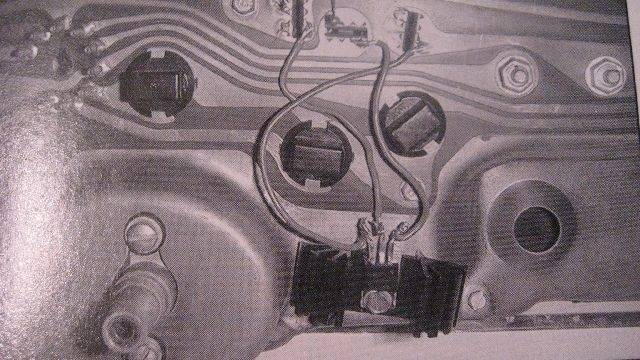

Well Ill leave you with the pictures at this point, they speak better than I anyhow! LOL

Oh and all of this stuf was less than 8.00

CAUTION!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

BE CAREFUL WHEN SOLDERING THESE COMPONENTS, THEY CANT TAKE PROLONGED HEAT FROM THE SOLDERING IRON!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

And yes it matters what wires go where, so copy them from the examples. The black and white pictures are directly from the mag!

Good luck guys!

Hey guys. Well I have spoken to my friend thats doing my gauge faces and its gonna be a few more weeks til I get them back so I decided while I have it apart, I may as well do a mod I seen a LONG time ago from Mopar Action magazine.

In the August 2000 Issue there is a write up on how to make your gauge cluster have stable needles! I have a bunch of old Mopar mags from when I was in the Navy on cruise. I just kept gettin' em' and collecting a little knowledge along the way.

Anyhow I thought Id transfer and summerize the procedure for anyone who hasnt seen this yet.

Here we go!

So here is the list of items they say you need.

1. A new regulator known as the "7805" in electronics world. (its the 3 pronged item) Got it from Radio Shack for less than a buck!

2. A small electrolytic capacitor. (the little barrel thing) Any value from 5-100uF. It must have a voltage rating of atleast 15 volts (more is fine) Mine as was the one in the magazine was a 10uF @ 100V. "Not critical" they say!

3. You need a heat sink to cool down the new regulator. I couldnt find one at Radio Shack so I made one from a strip of aluminum. I know from experiance with other things that these little buggers get really warm!

4. You need 3 pieces of wire anywhere from 20-26 gauge to tie all the components together.

NOTE: I bought the compund that helps to transfer thermal energy (heat) so that my home made heat sink may perform a little better. They say nothing about it in the artical.

Here is how this works: the regulator lets only a steady 5 volts go out, and the capacitor keeps any spikes from getting to the guages, so its somewhat like double protection there. Anyhow with all of this being better more reliable technology, it makes our old Mopars have some reliable readings!

Well Ill leave you with the pictures at this point, they speak better than I anyhow! LOL

Oh and all of this stuf was less than 8.00

CAUTION!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

BE CAREFUL WHEN SOLDERING THESE COMPONENTS, THEY CANT TAKE PROLONGED HEAT FROM THE SOLDERING IRON!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

And yes it matters what wires go where, so copy them from the examples. The black and white pictures are directly from the mag!

Good luck guys!