500 Hp Slant 6

A long time ago people did a lot with a lil, just took some $$$$ and a lot of thought.

1974 was the year...

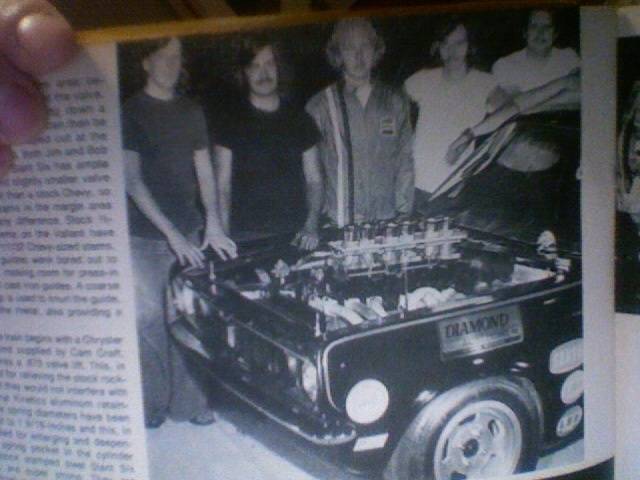

cricket modified 225 slant triple induction intake ports bored out and tubes brazed in [mega flow]/chevy trans what ever for the rear.

Here's a quote from the magazine on the cylinder head work and camshaft used, good stuff!

cars magazine writes..

''What's so hot about the slant 6?

Until last year, for instance, it powered a lil Anglia pannel truck and ran in E/altered, gernerally well under the record. Now, in the Criket it's running in L/Gas, still well under the record. Since L/ Gas has a 10-pound-per-cube weight break, a couple of hundred pounds was added to the Criket, all of it in the right place-over the rear wheels.''

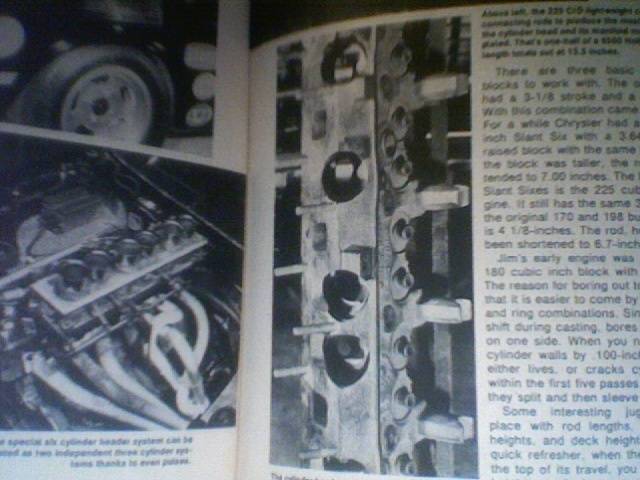

Probably the most striking single improvement and modification on the engine would be the cylinder head. the slant 6 starts out with a long ram manifold but Jim Witt definitely does it one better by transforming the cylinder head into a full independent runner head and manifold. For a good start, the intake passages were milled out to achieve a more straight line approach to the port/'valve' , cutting right through the water jacket and part of the valve cover rail. Tubes made up of 18 gauge exhaust pipe were form a snug fit at the head and extend well past the orig intake flange to create a new int flange. A transition manifold, in turn, provides the change in spacing from cylinder head ports to carburetor mounting flanges and also allows the carburetor to sit vertically. Tying the tubing and the cylinder head was something of a space work project. Both the head and the tube were copper plated prior to their being furnaced brazed in a neutral atmosphere . Vac-Hyd in detroit gets gets credit for this elaborate brazing procedure.''

''Jim Watt built his own flow bench and did an extensive amount of flow work to get the most out of this head. Part of the hump in the intake port was cut away to help the flow re-attach , and the back wall was carved out out on the intake side. The exhaust ports were enlarged and smoothed out. Also the exhaust valve guide projection and part of the hump and floor in the exh port were cut back. Jim Witt & Bob Brown section a few heads to find where they could and couldn't go.

The hump area [SHORT TURN] in the intake port is too critical to blindly grind on so don't.The stock 1.60 valves were swapped for 1.72's and the 1.36's were swapped to 1.50.The change was accomplished by use of early '61 corvette F.I valves w/ 11/32 stems.''

''During flow work Jim found that using the head of a pencil to create a disturbance at the valve seat near the valve head increased flow. This led him to try valve with a thick margin=,ore material between the seat and the head of the valve. This is easily done by cutting down a larger valve '' .

''The cam is a 'chrysler express' .675 lift solid, General Kenetics aluminum retainers, spring diameter increased to 1 9/16, Stock rockers that are plenty strong [folded steel] 'but with lock nuts'

Carbs are nascar 4500 1 11/16 straight bore from venturi down, each venturi feeds one cylinder, no balance pipe.=63 main jets & use of stacks to keep fog captured

fog=reversed pulse coming back to the carburetor, common with IR setups, you can use this if you keep it captured by say a stack on top like Jim Witt did.

The intake pipes are 13.5 inches from the top of the venturi to the top of the intake valve=perfect I.R length.

compression is 12.5 w/ 30cc chambers, 7'' rod was used with a 4.12 stroke bored+.100 over=238.

they used a mopar slant windage tray by means of 340 main cap bolts.

They changed dampeners and crank assembly's often do to torsional vibrations=torsioning.

aluminum oils pump would explode at the bearing so TRW cast iron or melling unit is used.

super T-10 trans and 6.17 gears are used''

In a nutshell

end.

I didn't wanna sit here and type the whole damn thing, don't have that much time..

A long time ago people did a lot with a lil, just took some $$$$ and a lot of thought.

1974 was the year...

cricket modified 225 slant triple induction intake ports bored out and tubes brazed in [mega flow]/chevy trans what ever for the rear.

Here's a quote from the magazine on the cylinder head work and camshaft used, good stuff!

cars magazine writes..

''What's so hot about the slant 6?

Until last year, for instance, it powered a lil Anglia pannel truck and ran in E/altered, gernerally well under the record. Now, in the Criket it's running in L/Gas, still well under the record. Since L/ Gas has a 10-pound-per-cube weight break, a couple of hundred pounds was added to the Criket, all of it in the right place-over the rear wheels.''

Probably the most striking single improvement and modification on the engine would be the cylinder head. the slant 6 starts out with a long ram manifold but Jim Witt definitely does it one better by transforming the cylinder head into a full independent runner head and manifold. For a good start, the intake passages were milled out to achieve a more straight line approach to the port/'valve' , cutting right through the water jacket and part of the valve cover rail. Tubes made up of 18 gauge exhaust pipe were form a snug fit at the head and extend well past the orig intake flange to create a new int flange. A transition manifold, in turn, provides the change in spacing from cylinder head ports to carburetor mounting flanges and also allows the carburetor to sit vertically. Tying the tubing and the cylinder head was something of a space work project. Both the head and the tube were copper plated prior to their being furnaced brazed in a neutral atmosphere . Vac-Hyd in detroit gets gets credit for this elaborate brazing procedure.''

''Jim Watt built his own flow bench and did an extensive amount of flow work to get the most out of this head. Part of the hump in the intake port was cut away to help the flow re-attach , and the back wall was carved out out on the intake side. The exhaust ports were enlarged and smoothed out. Also the exhaust valve guide projection and part of the hump and floor in the exh port were cut back. Jim Witt & Bob Brown section a few heads to find where they could and couldn't go.

The hump area [SHORT TURN] in the intake port is too critical to blindly grind on so don't.The stock 1.60 valves were swapped for 1.72's and the 1.36's were swapped to 1.50.The change was accomplished by use of early '61 corvette F.I valves w/ 11/32 stems.''

''During flow work Jim found that using the head of a pencil to create a disturbance at the valve seat near the valve head increased flow. This led him to try valve with a thick margin=,ore material between the seat and the head of the valve. This is easily done by cutting down a larger valve '' .

''The cam is a 'chrysler express' .675 lift solid, General Kenetics aluminum retainers, spring diameter increased to 1 9/16, Stock rockers that are plenty strong [folded steel] 'but with lock nuts'

Carbs are nascar 4500 1 11/16 straight bore from venturi down, each venturi feeds one cylinder, no balance pipe.=63 main jets & use of stacks to keep fog captured

fog=reversed pulse coming back to the carburetor, common with IR setups, you can use this if you keep it captured by say a stack on top like Jim Witt did.

The intake pipes are 13.5 inches from the top of the venturi to the top of the intake valve=perfect I.R length.

compression is 12.5 w/ 30cc chambers, 7'' rod was used with a 4.12 stroke bored+.100 over=238.

they used a mopar slant windage tray by means of 340 main cap bolts.

They changed dampeners and crank assembly's often do to torsional vibrations=torsioning.

aluminum oils pump would explode at the bearing so TRW cast iron or melling unit is used.

super T-10 trans and 6.17 gears are used''

In a nutshell

end.

I didn't wanna sit here and type the whole damn thing, don't have that much time..