Finally, got my 5.9 Dart to the track. It went well, then it went to hell.

I'm totally happy with the hughes. The price is right.

I will not be even close to 7000 rpm. I'll probably limit the engine to 6500 to fall back on about 6000-6200 on the 1-2.

For the price, there is nothing IMO that is really comparable with maybe the exception of the harlands, but I really dont know about them. There are some from racer brown, but the pics I saw of them were ****.

I am not up for paying over a grand for rockers though when I really dont need them on a motor, but when I do need them....

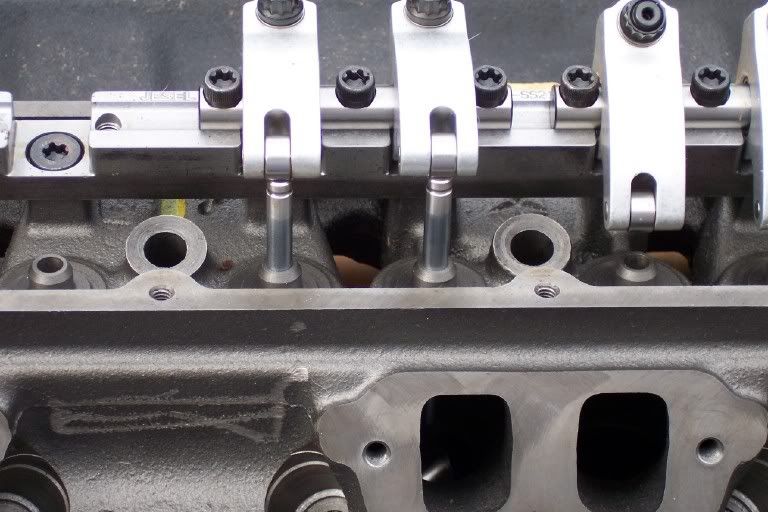

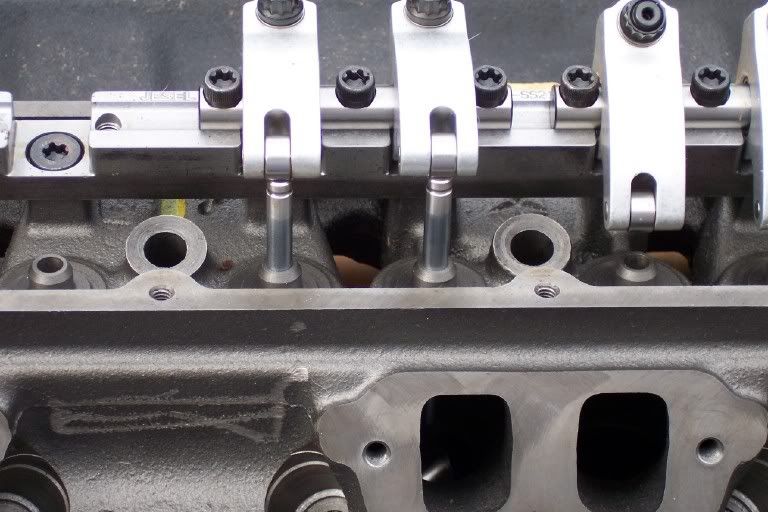

check these out! hehe

:yawinkle:

I'm totally happy with the hughes. The price is right.

I will not be even close to 7000 rpm. I'll probably limit the engine to 6500 to fall back on about 6000-6200 on the 1-2.

For the price, there is nothing IMO that is really comparable with maybe the exception of the harlands, but I really dont know about them. There are some from racer brown, but the pics I saw of them were ****.

I am not up for paying over a grand for rockers though when I really dont need them on a motor, but when I do need them....

check these out! hehe

:yawinkle: