The vacuum gauge in the dash on my ‘67 with the rally dash was not connected to the engine when I bought it. I have not found a photo of the routing of the vacuum line or where it connects to the engine. Anyone got a good description or photo?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

‘67 Barracuda vacuum gauge connection

- Thread starter Bobacuda

- Start date

-

DesertRat

Leading edge boomer

There should be a brass 1/4" fitting in the intake manifold with a 1/8" male hose end. From there, through the firewall grommet and to the vacuum gauge. Since yours is not hooked up look for a 1/4" NPT plug on the left side of your intake manifold. That is where the fitting would install.

You can also connect it to the carburetor on a full manifold vacuum port if you have one. That is where mine is connected.

That's it. Use one of them. For routing. Of course there isn't an original to copy for a '67 318 2bbl, but it should go back to the firewall and then through a grommet.The engine I need to hook up is a 318, 2 bbl. The manifold has a vacuum connection for the power brake booster that has two smaller, capped ports.

My car was originally a 225, but my guess is the grommet location was the same for v-8 with the vac gage.

That's the original hose. It's a smaller OD than the typical vac hose from the parts stores.

There were two occasions when I put the instrument panel back in and forget to attach this vacuum tubing to the gauge. It's pretty much impossible to connect from underneath too.

So... I got smart and created some markings. For this vacuum tube, I used some white heat shrink tubing that came from Harbor Freight over the black rubber tubing to make it more noticeable. Then I cut it about 5 inches behind the gauge and put a inline connector there.

My round harness connector has one inch long piece of blue zip tie super glued to its outside marking where the locating key in its center is (idea taken from the factories V notch on a steering box coupling), and its wrapped in white electrical tape. I can see and feel the little piece of zip tie so I don't need to see the factories key in the center to know where up/orientation is.

I didn't come up with a good orientation helper for the inline connector on the smaller board. Since that time another member here showed a slick mod for it. The 3 wires soldered onto the board, male and female harness connectors inline away from the board.

So... I got smart and created some markings. For this vacuum tube, I used some white heat shrink tubing that came from Harbor Freight over the black rubber tubing to make it more noticeable. Then I cut it about 5 inches behind the gauge and put a inline connector there.

My round harness connector has one inch long piece of blue zip tie super glued to its outside marking where the locating key in its center is (idea taken from the factories V notch on a steering box coupling), and its wrapped in white electrical tape. I can see and feel the little piece of zip tie so I don't need to see the factories key in the center to know where up/orientation is.

I didn't come up with a good orientation helper for the inline connector on the smaller board. Since that time another member here showed a slick mod for it. The 3 wires soldered onto the board, male and female harness connectors inline away from the board.

There were two occasions when I put the instrument panel back in and forget to attach this vacuum tubing to the gauge. It's pretty much impossible to connect from underneath too.

So... I got smart and created some markings. For this vacuum tube, I used some white heat shrink tubing that came from Harbor Freight over the black rubber tubing to make it more noticeable. Then I cut it about 5 inches behind the gauge and put a inline connector there.

My round harness connector has one inch long piece of blue zip tie super glued to its outside marking where the locating key in its center is (idea taken from the factories V notch on a steering box coupling), and its wrapped in white electrical tape. I can see and feel the little piece of zip tie so I don't need to see the factories key in the center to know where up/orientation is.

I didn't come up with a good orientation helper for the inline connector on the smaller board. Since that time another member here showed a slick mod for it. The 3 wires soldered onto the board, male and female harness connectors inline away from the board.

Great ideas. When I rebuilt my cluster and put it back in, I thought I was done. Have had it out twice since then (in about a year). Wish I had thought of this.

yeah I learned the hard way , do everything possible to avoid repeated R&R. Will I was servicing these gauges for other owners I advised them to do the same. My most recent mistake was cheap bulb sockets from ebay. They started failing after about 3 years. Of course the failures were at turn indicators. Again impossible to access from underneath.Great ideas. When I rebuilt my cluster and put it back in, I thought I was done. Have had it out twice since then (in about a year). Wish I had thought of this.

Good luck with yours.

Bumping this up to ask if anyone knows of any places selling the original style thin wall vacuum tubing.

It looks similar to the original washer hose to the squirters but a size up.

The one in my car is OK but I've had to splice in the engine compartment.

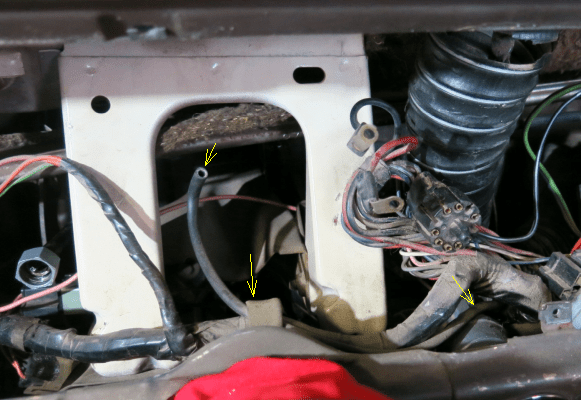

Related to earlier posts, here's a photo of the routing behind the instrument panel.

The original hose, where it is not stretched, measures 0.21" O.D.

The vacuum gage fitting measures 0.159" O.D.

Vacuum hose is usually listed by nominal sizing, which according to some tables does not always have the same nominal size as the fitting.

So the fitting may be nominal 5/32, or 1/8 and the hose could be nominal 7/64.

But I really don't know.

The easiest would be if someone is selling the correct hose.

It needs to be thin wall to go through the grommet and to fllow the route behind the dash without getting pinched.

It looks similar to the original washer hose to the squirters but a size up.

The one in my car is OK but I've had to splice in the engine compartment.

Related to earlier posts, here's a photo of the routing behind the instrument panel.

The original hose, where it is not stretched, measures 0.21" O.D.

The vacuum gage fitting measures 0.159" O.D.

Vacuum hose is usually listed by nominal sizing, which according to some tables does not always have the same nominal size as the fitting.

So the fitting may be nominal 5/32, or 1/8 and the hose could be nominal 7/64.

But I really don't know.

The easiest would be if someone is selling the correct hose.

It needs to be thin wall to go through the grommet and to fllow the route behind the dash without getting pinched.

Matt, I would go to parts store with gauge, they usually have a dispensing cabinet with different sizes.

Been theres.Matt, I would go to parts store with gauge, they usually have a dispensing cabinet with different sizes.

So far the closest OD I've found is Gates 27037, nominal 7/64 which is bit of stretch. OD measured .24

Cuda Al

Well-Known Member

This is what you need of similar,

1960-1965 Plymouth Parts | MP700214 | 1960-65 Mopar (except Charger & Hemi) - Intake Manifold Vacuum Fitting (1/8 connector) | Classic Industries

Alan

1960-1965 Plymouth Parts | MP700214 | 1960-65 Mopar (except Charger & Hemi) - Intake Manifold Vacuum Fitting (1/8 connector) | Classic Industries

Alan

Its supposed to be 1/8 I.D. tubing. No clamps requires tight fit to nipples. Thus the .16 O.D. of smooth nipple on gauge. Nipple at manifold has the small budge so it doesn't seize the entire length of nipple and will pull off with minimal effort, until it rots and breaks anyway. I would imagine their grommet was placed on the hose before placed into the firewall.

Here are some candidates from McMaster-Carr. Too soft and the tubing will collapse, high temperature can make it brittle over time. Fuel compatible? Only the first one has the right .21 OD but is red and only compatible with air and water. Good Luck

McMaster-Carr

McMaster-Carr

McMaster-Carr

McMaster-Carr

McMaster-Carr

McMaster-Carr

McMaster-Carr

McMaster-Carr

Redfish - Thank you - that makes sense now. I remember the intake manifold fitting that was on the car had a vacuum connection that probably was 1/8. I probably still have that fitting, which may or may not have been original to the car, but worked with the original hose.

Vacuum hoses for 1/8 fittings seem to be listed either as 1/8 (fitting size) or 7/64 (hose ID). Gates lists by hose ID.

Vacuum hoses for 1/8 fittings seem to be listed either as 1/8 (fitting size) or 7/64 (hose ID). Gates lists by hose ID.

That's too funny. I was looking through McMaster before going to sleep last night.Here are some candidates from McMaster-Carr. Too soft and the tubing will collapse, high temperature can make it brittle over time. Fuel compatible? Only the first one has the right .21 OD but is red and only compatible with air and water. Good Luck

McMaster-Carr

McMaster-Carr

McMaster-Carr

McMaster-Carr

I do think that's the answer though. The first one, nominal 1/8. Maybe not that exact hose but that size in vacuum hose.

I had a similar dilema with the vacuum and emmissions hoses on my '85 Grand wagoneer - except there was no grommet that needed to be slipped through. But there was what looked like 5 different sizes used and many had to be replaced. I found the table, used the parts and shop manuals for what it worth, measured what I could, and bought lots of hose to see what worked!

I've been upgrading to Viton for my vacuum tubing when I can. Tired of chasing cracked tubing, and I keep my cars forever.

I hear ya! I bought some 'silicone' hose from Summit during that project. Problem is getting any real info about it.

Gates washer/vac hose is EPDM, which isn't bad.

At least in the Barracuda there's room to route stuff away from the heat. The 85 GWagoneer is a nightmare in that respect.

edit: Gates has some info on silicone hose, not OD, on the current website

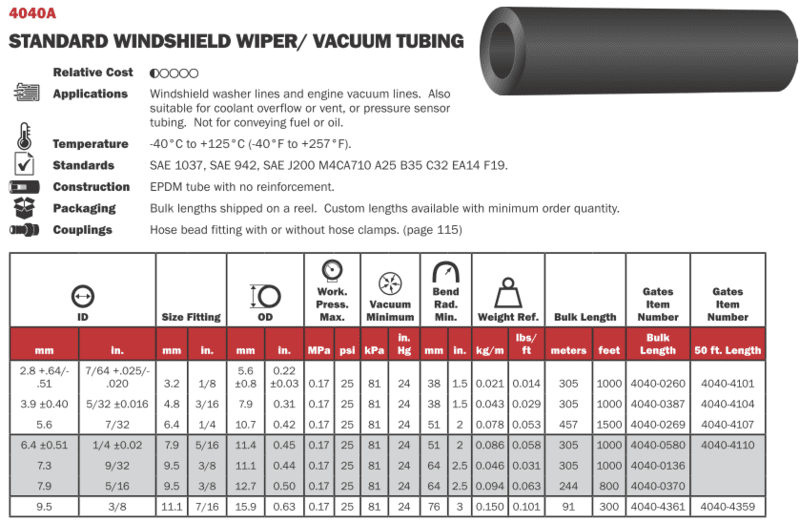

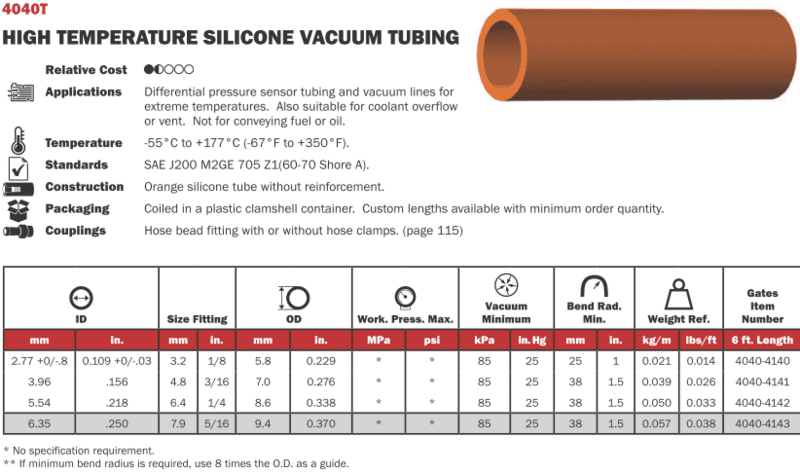

Silicone vacuum tubing

Non-reinforced EPDM vacuum tubing

from the industrial engine hose catalog 2018. pdf

Gates washer/vac hose is EPDM, which isn't bad.

At least in the Barracuda there's room to route stuff away from the heat. The 85 GWagoneer is a nightmare in that respect.

edit: Gates has some info on silicone hose, not OD, on the current website

Silicone vacuum tubing

Non-reinforced EPDM vacuum tubing

from the industrial engine hose catalog 2018. pdf

Last edited:

The silicone hose in that size will probably work if available in black. Still working on that possibilty.

In the meantime, I soaked the hose and the grommet in 3:1 solution of wintergreen oil and rubbing alcohol.

After a day or so the hose was much more flexible and the permanent set where it attached to the gage was gone.

So there's another option.

The grommet must have had other uses as well. Inside view.

The shine on the grommet is this cleaner/protector. Don't know that's its available. Not sure whats in it.

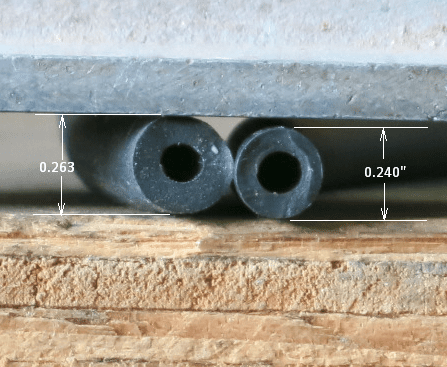

FWIW. Today I quickly remeasured the hose diameter using a vernier caliper and got 0.240"

That will pass through the grommet. Standard? washer/vac tube measured .267 (from Restoration Specialty Supply) and would not.

In the meantime, I soaked the hose and the grommet in 3:1 solution of wintergreen oil and rubbing alcohol.

After a day or so the hose was much more flexible and the permanent set where it attached to the gage was gone.

So there's another option.

The grommet must have had other uses as well. Inside view.

The shine on the grommet is this cleaner/protector. Don't know that's its available. Not sure whats in it.

FWIW. Today I quickly remeasured the hose diameter using a vernier caliper and got 0.240"

That will pass through the grommet. Standard? washer/vac tube measured .267 (from Restoration Specialty Supply) and would not.

Last edited:

Black Hose in a box marked Gates 27037 measured 0.245 o.d.

7/64 id (loose) for fittings designated 1/8" hose barbs.

Probably is what the box says but can't guarentee that.

This should work.

FWIW also have Gates 27075 box with orange silicone hose. Also 7/64 id. and 0.247 o.d.

7/64 id (loose) for fittings designated 1/8" hose barbs.

Probably is what the box says but can't guarentee that.

This should work.

FWIW also have Gates 27075 box with orange silicone hose. Also 7/64 id. and 0.247 o.d.

-