Grilled. After I selected the correct New Balance shoes.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1966 Factory V8 Valiant Signet Restoration For My Other Daughter

- Thread starter Jim Kueneman

- Start date

-

Scamp Rhonda

Well-Known Member

Nice! People don't realize how much tape we can go through working on this stuff. Lol.

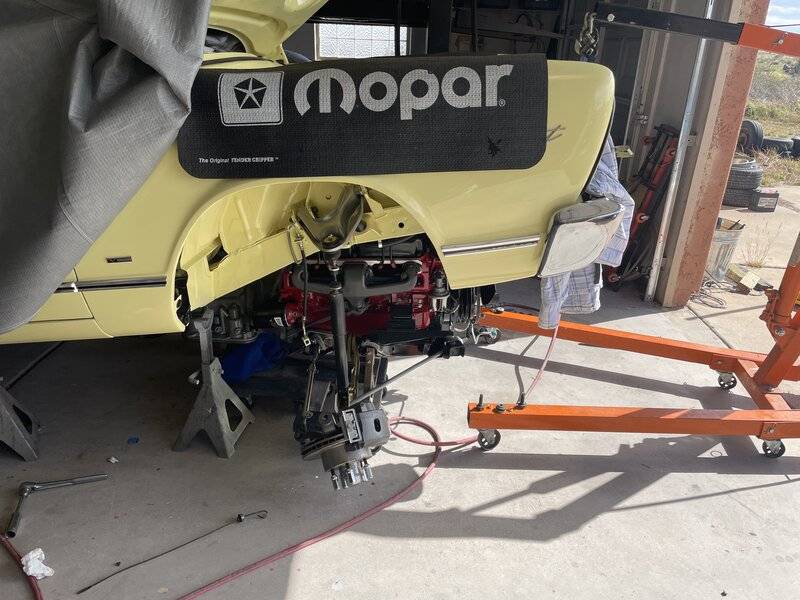

All mocked up and it is all looking great. Will start putting it together for real this week.

The disk brake booster and bolt in ‘73 proportioning valve was a fail. More to come once I get it on the lift and I decide how to do it. The proportioning valve was in the 2” it could not be for the factory manifold, of course.

The Accurate Exhaust would have been perfect if it did not have to space the LH manifold out 0.300” to clear the Edelbrock head. A bit of heat and some careful smacks with a hammer and it fits like a glove. Photos once I move it to the lift.

Need a bit of AC component restoration and get that bolted in. It’s coming together.

The disk brake booster and bolt in ‘73 proportioning valve was a fail. More to come once I get it on the lift and I decide how to do it. The proportioning valve was in the 2” it could not be for the factory manifold, of course.

The Accurate Exhaust would have been perfect if it did not have to space the LH manifold out 0.300” to clear the Edelbrock head. A bit of heat and some careful smacks with a hammer and it fits like a glove. Photos once I move it to the lift.

Need a bit of AC component restoration and get that bolted in. It’s coming together.

You Are amazing Jim.

Never recognize it as your car would you.

Karma, problems one day and the next this drops in my lap! Scored OEM power brake parts. Test fit when they get here and trip to Booster Exchange.

Last edited:

The rest of the HiPo 273 Accurate Exhaust fit like a glove. The Y pipe needed a tweak since I had to space the LH manifold out 0.300” to clear the Edelbrock head. Also it seems like maybe 273s did not have the engine to transmission brace on the RH side or the design was different as there was no way the pipe was going on with that bracket.

Also the 8.25” rear axle make my shaft too long. Need to take a bit off. 49.25” seems perfect.

Also the 8.25” rear axle make my shaft too long. Need to take a bit off. 49.25” seems perfect.

I would never recognise it as the car I sold to you. I'll be sending pictures to the original owner of the car also In their wildest dreams they would never expect to see their old car looking like it did when they bought it new & so close to the same color. Amazing,Jim

Been asked a few times what’s left. Not much. Weld a dryer together with R134 compatible desiccant, a install few miserable grill nuts, bead blast and clear coat the AC lines so they won’t re-rust, install the AC line o-rings, new expansion valve, paint and install the 4 barrel modified 340 throttle cable bracket, new pinion seal and install the yoke, driveshaft is at the shop getting shortened to the right length (8.25” swap), paint and install the AC clutch coil, get the factory booster restored and get the proportioning valve and brake line sorted out, install the RH fender star, install the A frame seals, replace a few bad AC vent blades with a ‘67 vent (blades look identical), install the K frame shields, connect the starter wires, tighten down the mocked up radiator parts, fill with fluids and fire it up.

A reminder of the journey over the last 18 months

Not a huge fan of restoring the AC lines like this but there was no finish left and this is the first item that I have ever had flash rust in the garage in the desert. Seymour’s Stainless Steel rattle can with Universal Clear over it for resistance to chemicals and grease. Many of my to dos are covered here. The main items are welding the dryer back up and finishing the brakes.

SWEET. Will she be ready for Nov. 12th? You have done a fantastic job Jim. Being on a fixed income & lacking your knowledge in my hands the Valiant would most likely still be gray,but it would run good. LOL Well done Jim.

Beautiful work !! Just wondering if you don't mind me asking, about how many hours to take that car from 1st picture to the 2nd picture ?A reminder of the journey over the last 18 months

View attachment 1716002524

View attachment 1716002525

Beautiful work !! Just wondering if you don't mind me asking, about how many hours to take that car from 1st picture to the 2nd picture ?

Rough guess 20 hours a week average for 18 months

SWEET. Will she be ready for Nov. 12th? You have done a fantastic job Jim. Being on a fixed income & lacking your knowledge in my hands the Valiant would most likely still be gray,but it would run good. LOL Well done Jim.

Doubtful. The brake booster will stop us.

Buttoned up the AC lines. Pressure tested it and then pulled a vacuum. Now I know when I weld up the other drier I know if it is the dryer if it leaks. Heater hoses installed, ordered a molded 90 degree for the valve to core. Mounted all the AC and shut off valve brackets. Plasti-dipped the line clamps. Installed a new wire on AC clutch and installed the clutch. Rear ground wire installed. The reproduction 4 barrel throttle cable bracket is a perfect fit (cut off the kickdown linkage). Just need to make sure of the position of the line clamp on the radiator support before drilling.

I was so sure I was done blasting. Guess not with the OEM booster. Need to blast and paint the pivot bracket and vacuum tank. The booster is on its way to Washington to Booster Exchange.

New yoke seal and ready for the driveshaft next week. Starter cables sorted out and installed. The 73 disk distribution/proportioning block repositioned and it won’t take a lot of work. The front is where I had it and where the 73 A Body lines want it. The rear is were it was. I think I have it in one of the Z bar holes if this was a stick or column shift. K-frame shields installed.

Early A dryer. All that is in them is black charcoal, like a fish filter and an string filter. Removed the charcoal and decided to reuse the filter so it has a filter. Inserted a R134 compatible desiccant bag. Made a crude brass sheet insert to make sure the bag did not plug the baffle hole between the cambers. A few bends make it fit tight so it won’t rattle. Make sure you remove the blow out valve before welding or you will melt the solder out! Once I know it works I may do a bit better job of body work to hide the grind marks better. It is holding a vacuum…..

B-i-n-g-o

Well-Known Member

Your "I'm waffling between satisfied and not" exceeds my "That turned out awesome!" That car is just rolling artwork!

Beautiful work! Showing off your skills very nicely Jim!...BTW ...where did you get the plug wire holder that I circled in the pic?

View attachment 1716004760

Summit. I would rather have plastic clip type.

-