You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2 post lift install -- documented

- Thread starter Righty Tighty

- Start date

-

Happy Thanksgiving, everyone.

Starting to set the rebar, and these tubes of epoxy go fast! I thought I could complete the job with two tubes, but one tube has only gotten me halfway through the first hole.

Starting to set the rebar, and these tubes of epoxy go fast! I thought I could complete the job with two tubes, but one tube has only gotten me halfway through the first hole.

One thing's for sure. You're doing this beyond right. Most people would have just bolted the lift right to the floor and never given it another thought. When you get done, that thing ain't goin nowhere! Nice work!

Thanks Rusty. I definitely don't want this thing to go anywhere when it's done, especially when someone's underneath it....haha.

Chuter

Member

Keep in mind they sell concrete by the yard. One big trench would about double it, plus the work to break the existing slab and dig out the sand below, and disposal of everything you dig out. Honestly, it looks very much like what I did a couple years ago. My biggest regret on the lift is that I waited so long to do it!

From the calculators I’ve used, I should be at about 1.5 yards total, not too bad.

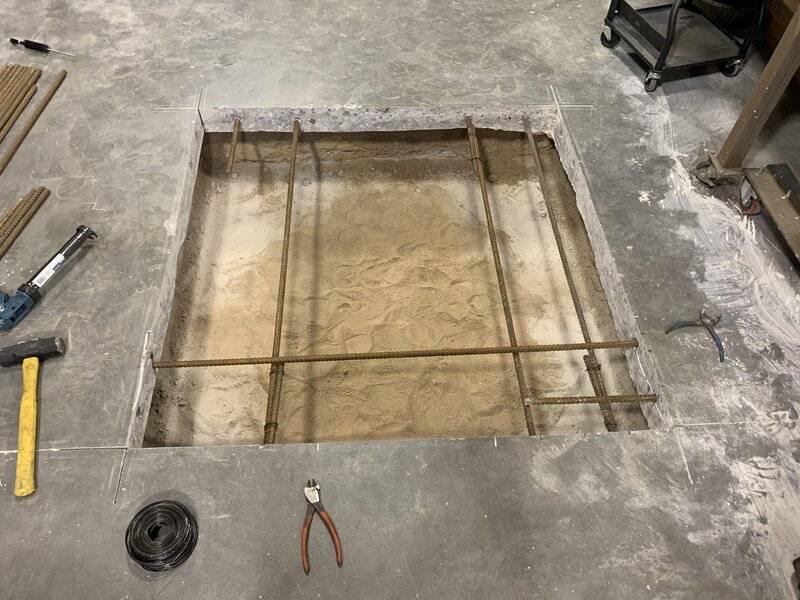

Finished setting the rebar yesterday, now it’s time to schedule the pour! Getting closer…

Finished setting the rebar yesterday, now it’s time to schedule the pour! Getting closer…

Pour day is finally here!

Ordered a short load, unfortunately their chute wasn’t long enough to pour directly into the holes, so we used wheelbarrows. Hired a day laborer to help, and boy am I glad I did. Watching a pro work is like poetry.

Ordered a short load, unfortunately their chute wasn’t long enough to pour directly into the holes, so we used wheelbarrows. Hired a day laborer to help, and boy am I glad I did. Watching a pro work is like poetry.

Concrete is finished. Now I’ll give it 30 days to cure, then it’s time to install!!

446acuda

Well-Known Member

I could google it, but I'll just ask. What is the epoxy for?Happy Thanksgiving, everyone.

Starting to set the rebar, and these tubes of epoxy go fast! I thought I could complete the job with two tubes, but one tube has only gotten me halfway through the first hole.

View attachment 1716014636

The epoxy is to affix the rebar to the existing slab.I could google it, but I'll just ask. What is the epoxy for?

Lift install is scheduled! They will be here February 7th and said it will take about 2 hours. The installers won't be handling any of the electrical, but that's okay, I can take care of wiring it to the panel myself.

I've purchased a couple underhoist screw jacks for the front and rear of the vehicle.

I've purchased a couple underhoist screw jacks for the front and rear of the vehicle.

Man you've done a great job on this.

Thanks, Rusty. My friends who aren't car guys think I'm crazy, but guess who's gonna be sniffin around my door when they need some work done??  But seriously, I've been working obscene hours to fund this, and you only live once, right? Tomorrow starts today.

But seriously, I've been working obscene hours to fund this, and you only live once, right? Tomorrow starts today.

The footers ended up being 14" thick, 3500 PSI mud, #5 rebar (5/8"), cured for 30 days. The concrete guy said I really didn't need the rebar with footers that thick, but it was already put in and it helps me sleep better at night knowing it's there.

I really do hope this thread can help someone in the future.

But seriously, I've been working obscene hours to fund this, and you only live once, right? Tomorrow starts today.

But seriously, I've been working obscene hours to fund this, and you only live once, right? Tomorrow starts today.The footers ended up being 14" thick, 3500 PSI mud, #5 rebar (5/8"), cured for 30 days. The concrete guy said I really didn't need the rebar with footers that thick, but it was already put in and it helps me sleep better at night knowing it's there.

I really do hope this thread can help someone in the future.

Excellent work, and great job of documenting the process.

JDMopar

Well-Known Member

You've done a good job with the prep. I kinda have an attitude of "If enough's enough, more is better" when it comes to doing things like this. My lift is a 4 post, and when I put a vehicle up to work on, I walk around to all 4 posts and physically check all 4 locks to make sure they are engaged. I'm too old to get mashed like a possum in the road!

Looking forward to see it put in.

Looking forward to see it put in.

Lift was installed yesterday! It took a little over three hours, and we had a couple hurdles to get over along the way. I don't know how this happened, but I mis-measured the height of the posts, and as a result, one of them wouldn't clear the ceiling where I had originally planned to set it. No problem, we moved it over 8-3/4" and we still had plenty of the deep slab to work with. The installer said that's exactly why they recommend a 4' x 4' square -- because that's a common situation. No big deal, now it's just off center in the bay by a bit.

The second hurdle is that the cross beam just in front of the lift is lower than the lift itself. This only means I may run into clearance issues with a taller vehicle, such as a full size truck. The lift is still very tall, so I'll still have plenty of room underneath.

Watching these guys work made me VERY glad I hired them. The process was pretty simple, but there were more steps than I anticipated and adjustments to the actual operation of the lift to be made that I wouldn't have a clue about. They tested/adjusted it under 110V power, but I still need to wire it for 220.

I told him this was my first lift, and he graciously gave me a rough tutorial and some of the dos/don'ts of lift operation, which I can't wait to put to use.

The second hurdle is that the cross beam just in front of the lift is lower than the lift itself. This only means I may run into clearance issues with a taller vehicle, such as a full size truck. The lift is still very tall, so I'll still have plenty of room underneath.

Watching these guys work made me VERY glad I hired them. The process was pretty simple, but there were more steps than I anticipated and adjustments to the actual operation of the lift to be made that I wouldn't have a clue about. They tested/adjusted it under 110V power, but I still need to wire it for 220.

I told him this was my first lift, and he graciously gave me a rough tutorial and some of the dos/don'ts of lift operation, which I can't wait to put to use.

mopowers

Well-Known Member

Thanks for documenting this. I've never had a lift, but hope to some day. What were some of the "dont's" that they mentioned?Lift was installed yesterday! It took a little over three hours, and we had a couple hurdles to get over along the way. I don't know how this happened, but I mis-measured the height of the posts, and as a result, one of them wouldn't clear the ceiling where I had originally planned to set it. No problem, we moved it over 8-3/4" and we still had plenty of the deep slab to work with. The installer said that's exactly why they recommend a 4' x 4' square -- because that's a common situation. No big deal, now it's just off center in the bay by a bit.

View attachment 1716046457

View attachment 1716046458

The second hurdle is that the cross beam just in front of the lift is lower than the lift itself. This only means I may run into clearance issues with a taller vehicle, such as a full size truck. The lift is still very tall, so I'll still have plenty of room underneath.

Watching these guys work made me VERY glad I hired them. The process was pretty simple, but there were more steps than I anticipated and adjustments to the actual operation of the lift to be made that I wouldn't have a clue about. They tested/adjusted it under 110V power, but I still need to wire it for 220.

View attachment 1716046459

View attachment 1716046460

I told him this was my first lift, and he graciously gave me a rough tutorial and some of the dos/don'ts of lift operation, which I can't wait to put to use.

View attachment 1716046461

View attachment 1716046462

The three main “don’ts” I remember are 1) don’t stop it without the lock engaged, 2) don’t bypass the locks on the arms and 3) don’t raise a vehicle from one end using only one arm.

These all seem obvious, but he said people do it all the time. I never even thought of that last one. He said they were called out to remove a lift that failed because the shop was doing that, and when they moved the vehicle there was a bloody mess.

These all seem obvious, but he said people do it all the time. I never even thought of that last one. He said they were called out to remove a lift that failed because the shop was doing that, and when they moved the vehicle there was a bloody mess.

I don't know where I went wrong with the post measurement in regards to ceiling clearance, but even after double checking my work, I still screwed up somehow. It's not the end of the world and it'll work just fine, it's just not perfect.

JDMopar

Well-Known Member

Looks like it all came together just fine. Now that you have a lift, you will have to adapt to new ways of working if you've never been used to one. It's a lot different (better) than laying on your back with cars on jackstands.

Thanks! It did come together okay, I'm just disappointed about the interference with the beam. When they said they were going to have to reposition it, I was almost certain they'd hit rebar. Somebody must be looking out for me though, because they missed the rebar on both posts.

And yes, I can't wait to not have to roll around on the floor. That makes for a long day.

And yes, I can't wait to not have to roll around on the floor. That makes for a long day.

Great job. Thanks for posting the progress.

Krooser

Building Chinese Free Engines since 1959...

I built my shop in '94...installed a used 9k Weaver lift in '96.

My shop floor is 4" six bag mix with fibermesh...

no wire or rebar.

I have never had a crack in my floor other than two hairline ones on the surface. I do have a good, well drained sandy base.

My shop floor is 4" six bag mix with fibermesh...

no wire or rebar.

I have never had a crack in my floor other than two hairline ones on the surface. I do have a good, well drained sandy base.

JDMopar

Well-Known Member

I thought about you and was happy for you again........while I was wallowing around in the floor removing the front suspension from my 20 year old Dakota to rebuild it! LOL.Thanks! It did come together okay, I'm just disappointed about the interference with the beam. When they said they were going to have to reposition it, I was almost certain they'd hit rebar. Somebody must be looking out for me though, because they missed the rebar on both posts.

And yes, I can't wait to not have to roll around on the floor. That makes for a long day.

-